Reinforced PTFE packing uses high-strength inorganic fibers to make up for the lack of strength of t...

Iron and steel smelting SEAL Explore More

Iron and steel smelting SEAL Explore More

Petroleum and Ship SEAl Explore More

Petroleum and Ship SEAl Explore More

Specialize in researching, manufacturing and selling various types of Flange Seal Explore More

Specialize in researching, manufacturing and selling various types of Flange Seal Explore More

Iron and steel smelting SEAL Explore More

Iron and steel smelting SEAL Explore More

Petroleum and Ship SEAl Explore More

Petroleum and Ship SEAl Explore More

Specialize in researching, manufacturing and selling various types of Flange Seal Explore More

Specialize in researching, manufacturing and selling various types of Flange Seal Explore More

Iron and steel smelting SEAL Explore More

Iron and steel smelting SEAL Explore More

Petroleum and Ship SEAl Explore More

Petroleum and Ship SEAl Explore More

customers of industrial.

Custom Sealing Gaskets, Sealing Packing, Rubber Products Suppliers

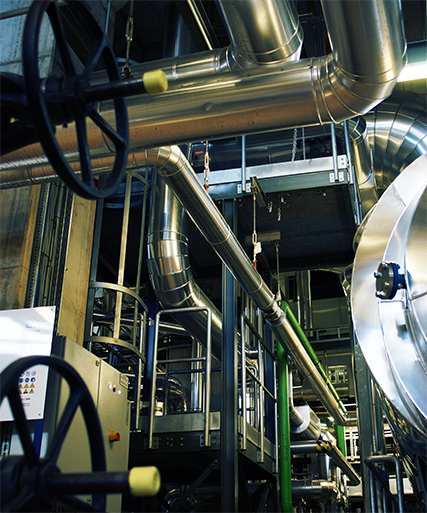

, we are a large comprehensive sealing technology enterprise, we specialize in researching, manufacturing and selling various types of seals, environment-friendly asbestos-free gaskets, specialized rubber material products and parts insulation materials for pneumatic and hydraulic systems. Moreover, we have formed a complete set with many industries such as shipping, power, iron and steel, chemistry, and machinery for many successive years.-

Gland Packing

-

Metal GasketMetal Gasket

Produced by a thin layer of metal-coated soft inorganic sealing filler with high heat resistance. Th...

-

Non Metallic Gasket&SheetNon Metallic Gasket&Sheet

It is suitable for gaskets needed in a wide range of fields. It is vulcanized with polymers and vari...

-

Graphite Seal ProductsGraphite Seal Products

It is an improved semi-metal gasket, which is the compound of expanded graphite. Its performance is ...

-

Gland PackingGland Packing

Reinforced PTFE packing uses high-strength inorganic fibers to make up for the lack of strength of t...

-

Metal GasketMetal Gasket

Produced by a thin layer of metal-coated soft inorganic sealing filler with high heat resistance. Th...

-

Non Metallic Gasket&SheetNon Metallic Gasket&Sheet

It is suitable for gaskets needed in a wide range of fields. It is vulcanized with polymers and vari...

-

Graphite Seal ProductsGraphite Seal Products

It is an improved semi-metal gasket, which is the compound of expanded graphite. Its performance is ...

-

Gland PackingGland Packing

Reinforced PTFE packing uses high-strength inorganic fibers to make up for the lack of strength of t...

-

Metal GasketMetal Gasket

Produced by a thin layer of metal-coated soft inorganic sealing filler with high heat resistance. Th...

-

Non Metallic Gasket&SheetNon Metallic Gasket&Sheet

It is suitable for gaskets needed in a wide range of fields. It is vulcanized with polymers and vari...

-

Graphite Seal ProductsGraphite Seal Products

It is an improved semi-metal gasket, which is the compound of expanded graphite. Its performance is ...

Founded in 2004 , which located on Xingyuan Road, Yuanzhu Industrial Park, in Taixing, Jiangsu Province. With the accumulated years of scientific experiments and manufacture, our company has possessed sound quality management manuals and monitoring systems.

Packing

Packing Graphite Gland Packing

Graphite Gland Packing Metal Gasket

Metal Gasket PTFE Gland Packing

PTFE Gland Packing Semi-metal Gasket

Semi-metal Gasket Nonmetal Sheet

Nonmetal Sheet

-

0

Years of In-depth industry expertise

-

0

Square meters company area

-

0+

Complete sealing Projects

-

0+

Dedicated skillful employees

Manufacturer in The Quality

-

Comprehensive Sealing Technology Enterprise

Comprehensive Sealing Technology Enterprise

The factory price is low, and professional technical engineers will answer your questions if you need.

-

Rich Experience in The Sealing Industry

Rich Experience in The Sealing Industry

Over 20 years of production experience, with semi-automatic and efficient precision production support.

-

Support OEM and ODM Customized Service

Support OEM and ODM Customized Service

strong R&D team, we can produce OEM and ODM systems, as well as tracking services during trade processes.

-

Complete After-sale Service

Complete After-sale Service

Professional foreign trade team, highly efficient and thoughtful after-sales service, 18h online

We are a large comprehensive sealing technology manufacturer and have more than 20 years of industry experience.

-

01Advanced Processing EquipmentView More+

Jintai Sealing has several imported production equipment, advanced production technology and production efficiency, laying the foundation for continued production.

-

02Complete Quality InspectionView More+

With the accumulated years of scientific experiments and manufacture, our company has complete quality management system and inspection equipment.

-

03Professional R&D TeamView More+

As a professional manufacturer we have a strong R&D team, we can develop and produce products according to the drawings or samples.

-

04Eco-friendly Technology ProcessView More+

Our products have achieved the CCS classification society quality system identification, and passed the CiT test for environmental protection.

Our comprehensive application cases can meet the application needs of customers in different industries.

Widely used in automobiles, motorcycles, ships, petrochemicals, power generation, metallurgy, machinery, and other industries.

Over 20 years' experience in the customized sealing processing service.

-

PTFE Graphite Gland Packing: A Comprehensive Guide to Flexible Graphite Gland Packing and Graphite Packing SealsRead More+

PTFE graphite gland packing is a high-performance sealing solution widely used in industrial applica...

-

Graphite Gasket Seals: Reliable Solutions for High-Temperature and High-Pressure ApplicationsRead More+

Exploring Graphite Gland Packing, Spiral/Metal-Toothed/Corrugated Metal Gaskets In industrial applic...

-

Graphite Filler Gasket: Superior Sealing Solutions for Industrial ApplicationsRead More+

Graphite-based sealing materials are widely used in industrial applications due to their excellent t...

-

PTFE Gland Packing for High Temperature Applications: A Reliable Sealing SolutionRead More+

In industrial environments where high temperatures and harsh chemicals are present, choosing the rig...

-

Non Metallic Gasket & Sheet Gasket: Essential Solutions for Industrial SealingRead More+

In industrial applications, sealing solutions play a critical role in ensuring leak-proof connection...

-

Spiral/Metal-Toothed/Corrugated Metal Gaskets: High-Performance Sealing SolutionsRead More+

Metal gaskets are critical components in industrial applications where high pressure, extreme temper...

-

PTFE Graphite Gland Packing: A Comprehensive Guide to Flexible Graphite Gland Packing and Graphite Packing SealsRead More+

PTFE graphite gland packing is a high-performance sealing solution widely used in industrial applica...

-

Graphite Gasket Seals: Reliable Solutions for High-Temperature and High-Pressure ApplicationsRead More+

Exploring Graphite Gland Packing, Spiral/Metal-Toothed/Corrugated Metal Gaskets In industrial applic...

-

Graphite Filler Gasket: Superior Sealing Solutions for Industrial ApplicationsRead More+

Graphite-based sealing materials are widely used in industrial applications due to their excellent t...

-

PTFE Gland Packing for High Temperature Applications: A Reliable Sealing SolutionRead More+

In industrial environments where high temperatures and harsh chemicals are present, choosing the rig...

-

Non Metallic Gasket & Sheet Gasket: Essential Solutions for Industrial SealingRead More+

In industrial applications, sealing solutions play a critical role in ensuring leak-proof connection...

-

Spiral/Metal-Toothed/Corrugated Metal Gaskets: High-Performance Sealing SolutionsRead More+

Metal gaskets are critical components in industrial applications where high pressure, extreme temper...

-

PTFE Graphite Gland Packing: A Comprehensive Guide to Flexible Graphite Gland Packing and Graphite Packing SealsRead More+

PTFE graphite gland packing is a high-performance sealing solution widely used in industrial applica...

-

Graphite Gasket Seals: Reliable Solutions for High-Temperature and High-Pressure ApplicationsRead More+

Exploring Graphite Gland Packing, Spiral/Metal-Toothed/Corrugated Metal Gaskets In industrial applic...

-

Graphite Filler Gasket: Superior Sealing Solutions for Industrial ApplicationsRead More+

Graphite-based sealing materials are widely used in industrial applications due to their excellent t...

-

PTFE Gland Packing for High Temperature Applications: A Reliable Sealing SolutionRead More+

In industrial environments where high temperatures and harsh chemicals are present, choosing the rig...

Copyright © 2024. Jiangsu Jintai Sealing Technology Co., Ltd. All rights reserved. Custom Sealing Gaskets, Sealing Packing, Rubber Products

Eng

Eng  русский

русский