Non Metallic Gasket & Sheet Gasket: Essential Solutions for Industrial Sealing

2025.06.01

2025.06.01

Industry News

Industry News

In industrial applications, sealing solutions play a critical role in ensuring leak-proof connections, enhancing safety, and improving operational efficiency. Non-Metallic Gaskets and Sheet Gaskets are widely used due to their flexibility, chemical resistance, and adaptability to various operating conditions. This article explores key aspects of these gaskets, focusing on high-temperature applications, compressed non-asbestos gasket sheets, and custom cutting services.

9900/9900N Improved Non Asbestos Filled PTFE Sheet Gasket Material

1. Non Metallic Gasket for High-Temperature Applications

Why Choose Non-Metallic Gaskets for High Heat?

Non-metallic gaskets are ideal for high-temperature environments due to their ability to withstand extreme heat without degrading. Materials such as graphite, PTFE (Teflon), and ceramic fiber offer excellent thermal stability, making them suitable for:

Power plants & boilers

Petrochemical refineries

Aerospace & automotive exhaust systems

Key Benefits:

Thermal Resistance – Can endure temperatures up to 1000°C (1832°F) depending on the material.

Chemical Inertness – Resistant to corrosive fluids and gases.

Compression Recovery – Maintains seal integrity under thermal cycling.

Latest Trend: Eco-friendly high-temperature gaskets made from bio-based materials are gaining traction in sustainable industries.

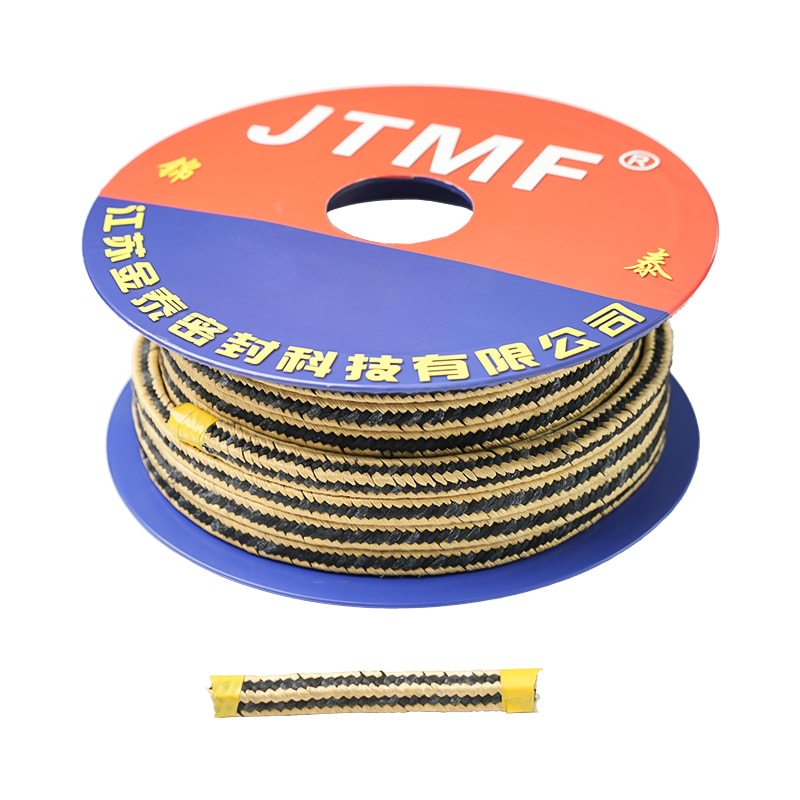

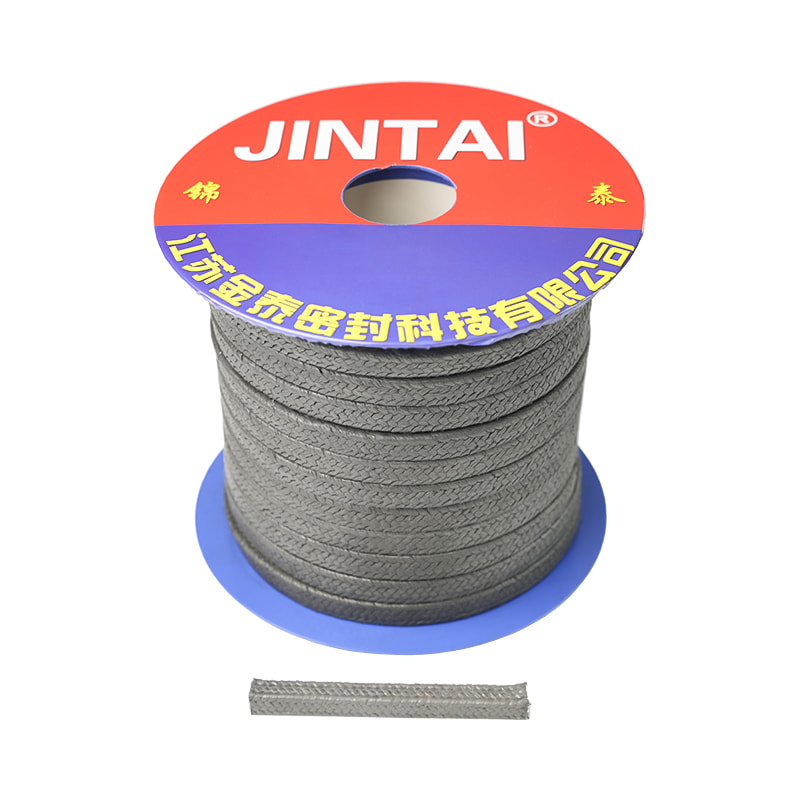

2. Compressed Non-Asbestos Gasket Sheet Suppliers

The Shift from Asbestos to Safer Alternatives

With the ban on asbestos due to health hazards, compressed non-asbestos (CNA) gasket sheets have become the preferred choice. These sheets are reinforced with aramid fibers, glass fibers, and elastomeric binders, offering superior sealing performance.

Applications:

Oil & gas pipelines

Chemical processing plants

Marine & heavy machinery

Choosing the Right Supplier:

When sourcing CNA gasket sheets, consider:

Material Compliance – Meets ASTM F104, BS 2815, and DIN 28090 standards.

Custom Thickness & Density – Available in various grades (e.g., 1.5mm to 6mm).

Global Supply Chain – Reliable suppliers with ISO 9001 certification.

Market Insight: Leading suppliers now offer digital inventory tracking and fast global shipping to meet urgent industry demands.

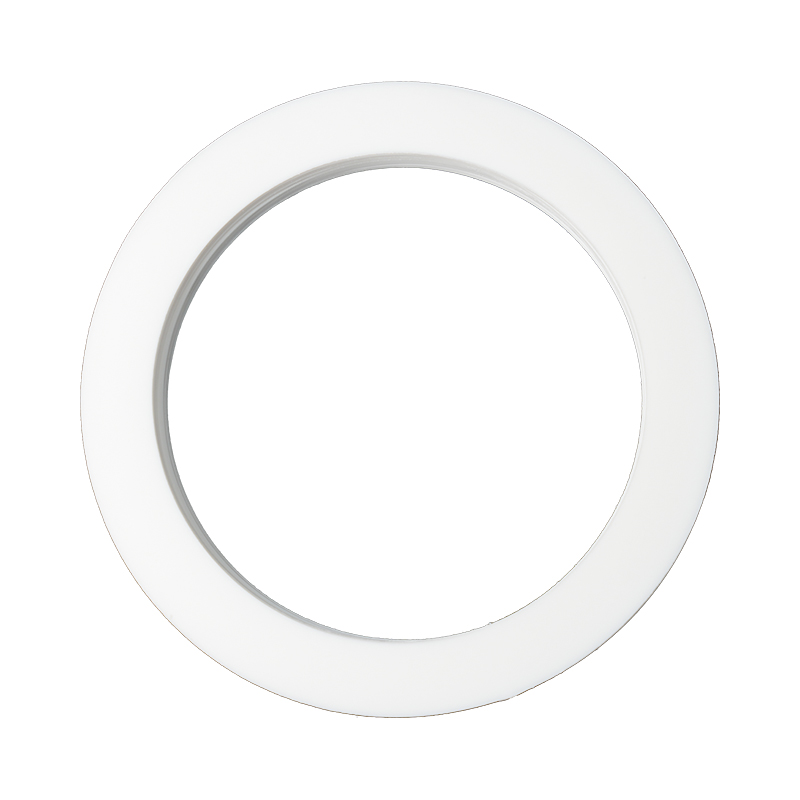

3. Custom Sheet Gasket Cutting Service

Precision Cutting for Optimal Performance

Off-the-shelf gaskets may not always fit specialized equipment. Custom sheet gasket cutting services ensure precise dimensions, reducing leaks and downtime.

Technologies Used:

CNC Waterjet Cutting – For intricate shapes without material distortion.

Laser Cutting – High precision for thin materials like PTFE and rubber.

Die Cutting – Cost-effective for bulk orders.

Industries Benefiting from Custom Cutting:

Food & Pharmaceuticals – Hygienic, contamination-free seals.

Renewable Energy – Gaskets for solar panel and wind turbine assemblies.

HVAC Systems – Custom-fit gaskets for ducting and compressors.

Emerging Trend: AI-driven automated cutting systems are improving accuracy and reducing material waste.

Non-Metallic Gaskets and Sheet Gaskets are indispensable in modern industries, offering durability, safety, and efficiency. Whether you need high-temperature-resistant gaskets, certified non-asbestos sheets, or custom-cut solutions, selecting the right material and supplier is crucial.

Eng

Eng  русский

русский