Why Graphite Gland Packing is Revolutionizing Industrial Sealing Solutions Industrial sealing technologies have evolved significantly, with graphite g...

READ MORE

-

-

Comprehensive Understanding of Graphite Gland Packing Technology Graphite gland packing represents a significant advancement in sealing technology, of...

READ MORE -

Graphite gland packing is a cornerstone in industrial sealing, prized for its exceptional performance in demanding environments. This article delves ...

READ MORE -

High-temperature metal gaskets are critical components in industries such as oil & gas, power generation, chemical processing, and aerospace. They...

READ MORE -

Gaskets play a critical role in industrial sealing, ensuring leak-proof connections in high-pressure and high-temperature environments. Among the most...

READ MORE

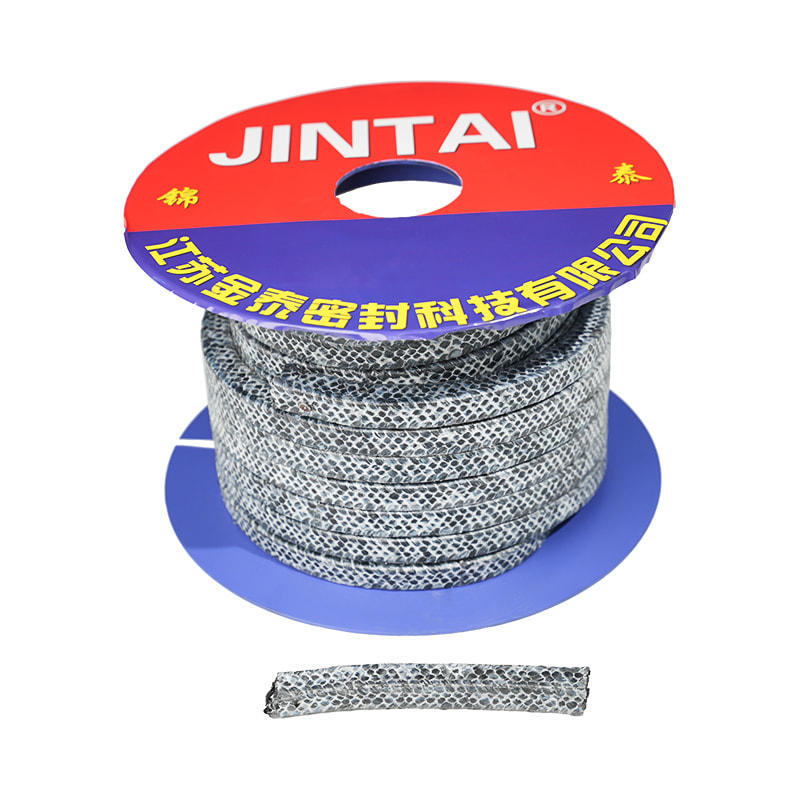

What materials are mainly composed of Graphite Gland Packing? How does the selection of these materials affect its overall performance?

Graphite Gland Packing (graphite packing seal) is mainly composed of graphite matrix and other reinforcing or auxiliary materials. The selection of these materials has a crucial impact on its overall performance.

Main constituent materials

Graphite matrix:

Graphite is the main component of Graphite Gland Packing. It has self-lubricity, dimensional stability, gas and liquid impermeability, and corrosion resistance.

The low coefficient of friction, high thermal conductivity and good sliding speed of graphite make it soft and compliant under high temperature and high pressure conditions, thus providing excellent sealing performance.

Reinforcement materials:

In order to improve the extrusion resistance and pressure bearing capacity of Graphite Gland Packing, reinforcement materials such as Inconel wire (a high-strength, corrosion-resistant alloy material) or glass fiber are usually added.

These reinforcement materials are combined with the graphite matrix by weaving or winding to form a composite filler with higher strength and stability.

Auxiliary materials:

Some Graphite Gland Packing may also contain inhibitors or other additives to improve its chemical resistance, high temperature resistance or improve its processing performance.

The impact of material selection on overall performance

Sealing performance:

The self-lubricity and low friction coefficient of the graphite substrate help reduce the wear of the sealing surface and improve the sealing performance.

The addition of reinforcement materials can further improve the packing's anti-extrusion and pressure bearing capacity, ensuring that it can still maintain a good sealing effect under extreme working conditions.

High temperature and corrosion resistance:

The high thermal stability and corrosion resistance of graphite enable Graphite Gland Packing to work stably in high temperature and corrosive media.

The addition of auxiliary materials can further enhance these properties and make it suitable for a wider range of industrial environments.

Mechanical properties:

The addition of reinforcement materials significantly improves the mechanical properties of Graphite Gland Packing, such as tensile strength, shear strength and fatigue resistance.

The improvement of these properties helps to extend the service life of the packing and reduce equipment maintenance costs.

Processing performance:

The appropriate material selection and manufacturing process can ensure that Graphite Gland Packing has good processing performance and is easy to manufacture and install.

Compared with traditional packing seals, in what aspects does Graphite Gland Packing show obvious performance advantages?

Compared with traditional packing seals, Graphite Gland Packing shows obvious performance advantages in many aspects. Here are some major advantages:

High temperature resistance:

Graphite Gland Packing can maintain excellent sealing performance in high temperature environments due to the extremely high thermal stability of its main component graphite. In contrast, traditional packing seals may soften, deform or lose their sealing effect under high temperature conditions.

Corrosion resistance:

Graphite material has excellent corrosion resistance to a variety of chemical media, which makes Graphite Gland Packing particularly suitable for occasions handling corrosive media. Traditional packing seals may be corroded in corrosive media, resulting in reduced sealing performance.

Self-lubricity:

Graphite has good self-lubricity and can form a lubricating film during the sealing process to reduce friction and wear. This feature makes Graphite Gland Packing perform well in equipment that requires frequent start-up and shutdown, and can extend the service life of the equipment. Traditional packing seals may require additional lubricants to maintain their sealing effect.

Stable sealing effect: The sealing effect of Graphite Gland Packing will not change significantly due to changes in the temperature, pressure, etc. of the liquid or gas, so it has stable sealing performance within a certain range. In contrast, traditional packing seals may leak or fail to seal under extreme conditions.

Long service life: Due to its excellent high temperature resistance, corrosion resistance and self-lubrication properties, Graphite Gland Packing usually has a longer service life than traditional packing seals. This helps reduce equipment downtime and maintenance costs.

Wide range of applications: Graphite Gland Packing is suitable for sealing various rotating and reciprocating equipment, including pumps, valves, compressors, etc. Its wide applicability enables it to be used in multiple industrial fields.

Environmental protection: In some cases, Graphite Gland Packing may use more environmentally friendly materials and manufacturing processes, reducing pollution to the environment. In contrast, traditional packing seals may contain ingredients that are harmful to the environment or produce harmful substances during use.

Eng

Eng  русский

русский