Graphite Gasket Seals: Reliable Solutions for High-Temperature and High-Pressure Applications

2025.05.10

2025.05.10

Industry News

Industry News

Exploring Graphite Gland Packing, Spiral/Metal-Toothed/Corrugated Metal Gaskets

In industrial applications where extreme temperatures, corrosive environments, and high pressures are common, selecting the right sealing solution is critical. Among the most effective options are graphite-based seals, including Graphite Gland Packing, Spiral Wound Gaskets, Metal-Toothed Gaskets, and Corrugated Metal Gaskets.

Mechanical/Water Pump PTFE Seal Packing Ramie Fiber Gland Packing

Graphite Gasket Seals: Superior Performance in Demanding Conditions

Graphite gasket seals are widely used in industries such as oil & gas, chemical processing, power generation, and refineries due to their exceptional properties:

High-Temperature Resistance: Graphite can withstand temperatures up to 1000°C (1832°F) in non-oxidizing environments.

Chemical Inertness: Resistant to most acids, alkalis, and solvents, making it ideal for corrosive applications.

Excellent Compressibility & Recovery: Ensures a tight seal even under fluctuating pressures and thermal cycling.

Low Friction & Self-Lubricating: Reduces wear on mating surfaces, extending equipment life.

Common types of graphite gaskets include:

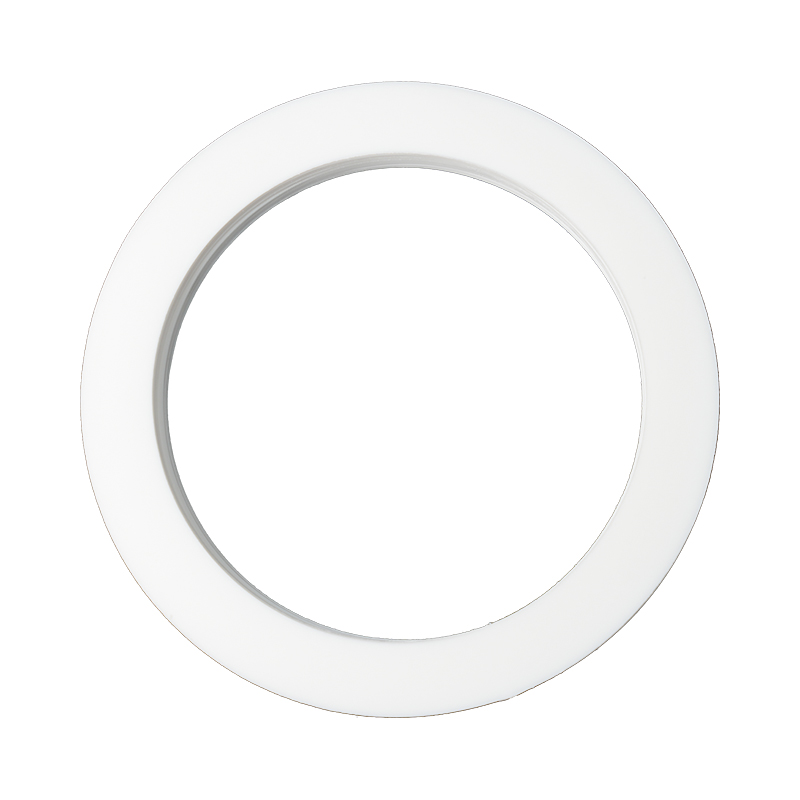

Flexible Graphite Gaskets – Used in flanges, heat exchangers, and valve seals.

Graphite Foil Gaskets – Ideal for irregular surfaces due to their conformability.

Reinforced Graphite Gaskets – Incorporate metal inserts for added strength.

Comparison with Other High-Performance Sealing Solutions

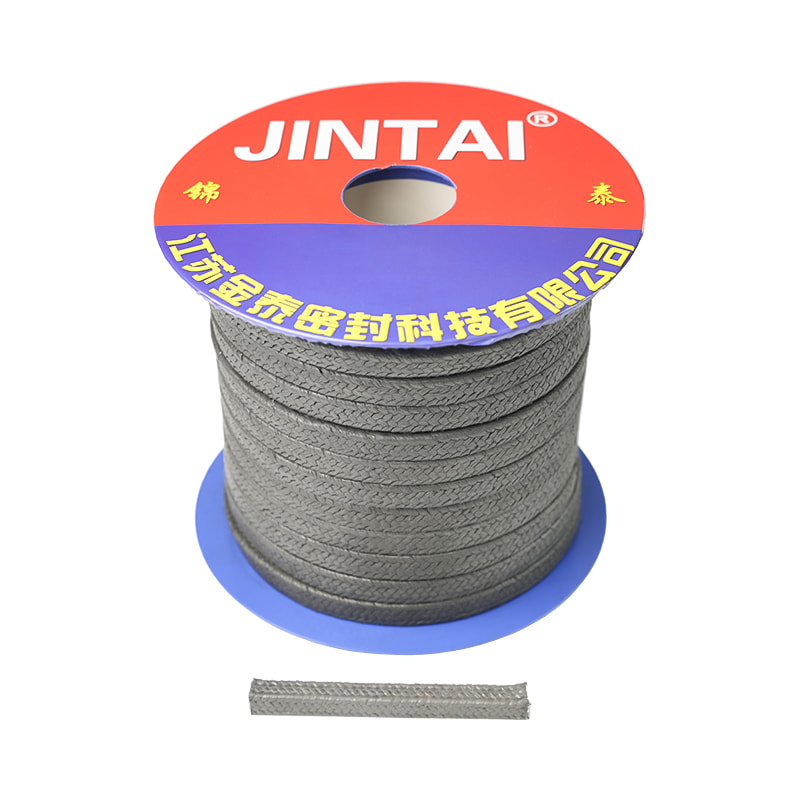

1. Graphite Gland Packing

Used in rotary and reciprocating equipment (pumps, valves, agitators).

Composed of braided graphite yarn for low leakage and high thermal stability.

Suitable for steam, hot oil, and chemical services.

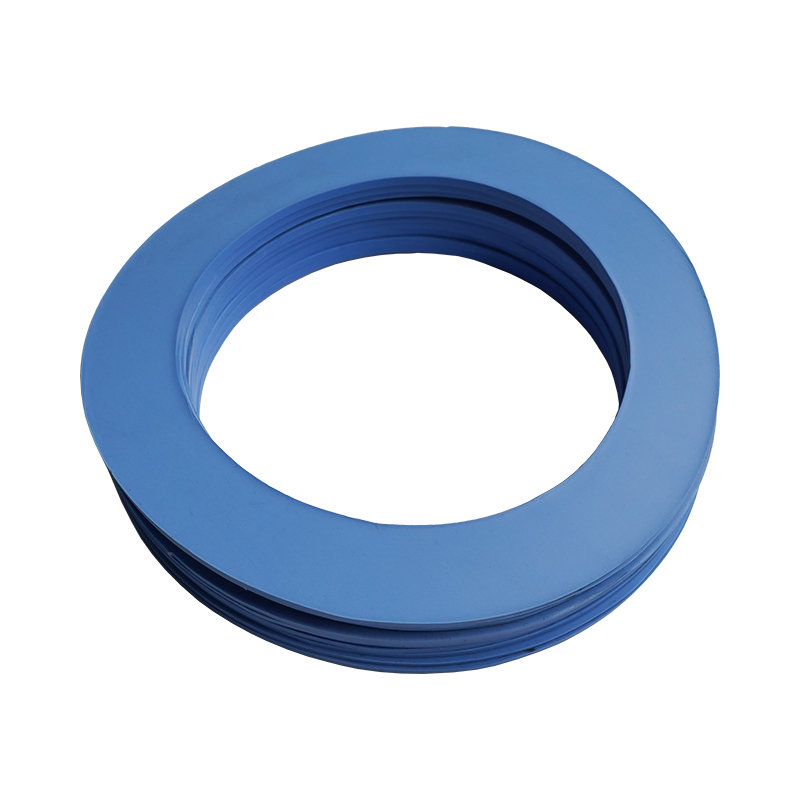

2. Spiral Wound Gaskets (Metal-Toothed & Corrugated Metal Gaskets)

Spiral Wound Gaskets: Combine graphite filler with metal windings (stainless steel, Inconel) for high-pressure sealing.

Metal-Toothed Gaskets: Feature serrated metal surfaces for bite-in sealing in flange connections.

Corrugated Metal Gaskets: Use a ridged design for enhanced compression and resilience.

Choosing the Right Seal for Your Application

For extreme heat & chemical resistance → Graphite Gasket Seals

For dynamic sealing in pumps & valves → Graphite Gland Packing

For high-pressure flange connections → Spiral Wound or Metal-Toothed Gaskets

For resilient, compression-resistant sealing → Corrugated Metal Gaskets

Eng

Eng  русский

русский