How does GLAND PACKING ensure the sealing performance of pipeline joints?

2024.06.06

2024.06.06

Industry News

Industry News

In the petrochemical industry, how does GLAND PACKING ensure the sealing performance of pipeline joints?

In the petrochemical industry, GLAND PACKING plays a vital role in ensuring the sealing performance of pipeline joints. The following is a detailed explanation of how GLAND PACKING ensures the sealing performance of pipeline joints:

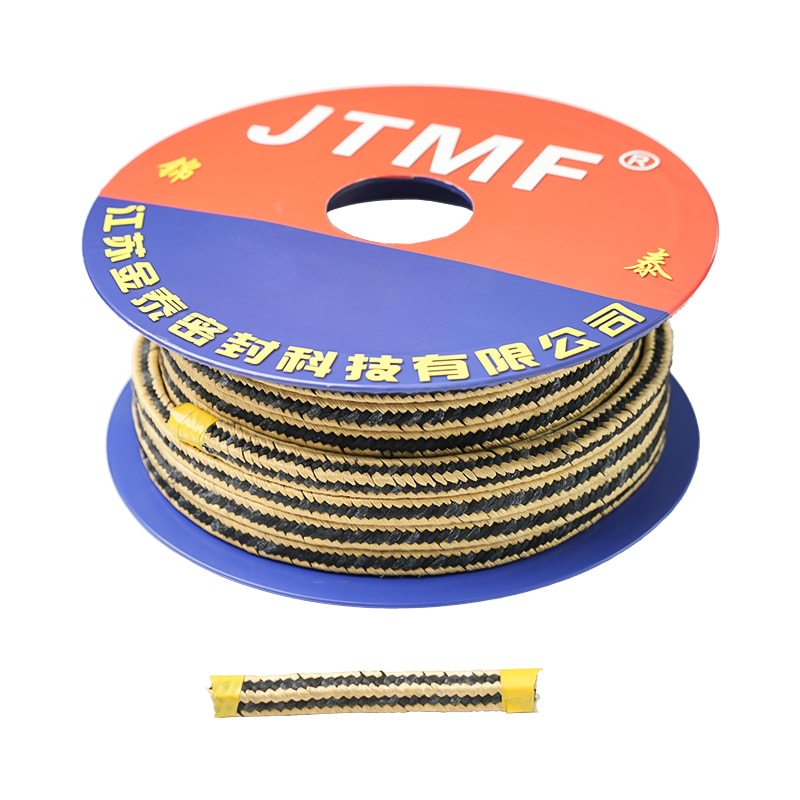

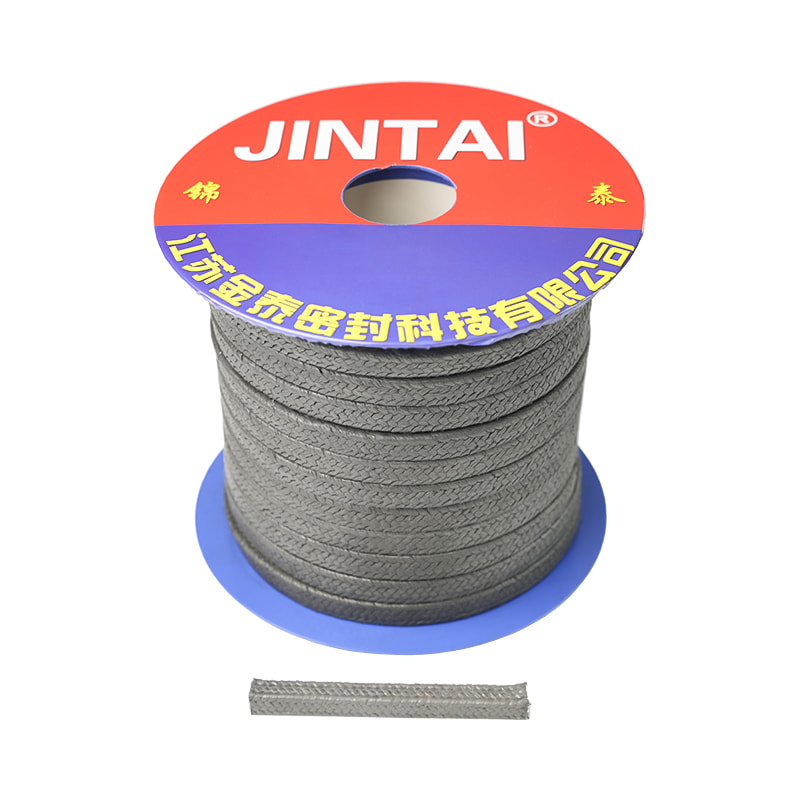

Multi-layer braided structure:

GLAND PACKING usually adopts a multi-layer braided structure, which can fit closely to the surface of the pipeline joint to form one or more sealing barriers.

This multi-layer design not only increases the reliability of the seal, but also maintains stable sealing performance under different pressure and temperature conditions.

Material selection and characteristics:

The material selection of GLAND PACKING is very important. It is usually necessary to select high temperature resistant, corrosion resistant and wear resistant materials to adapt to the harsh environment in the petrochemical industry.

Commonly used materials include high temperature resistant rubber, graphite, stainless steel wire, etc., which can maintain stable performance in high temperature, high pressure and corrosive media.

Easy to install and adjust:

GLAND PACKING is usually designed as a structure that is easy to install and disassemble, which makes it more convenient and quick to seal at pipeline joints.

Through proper compression and adjustment, it can ensure that GLAND PACKING fits tightly with the pipeline joints to achieve a good sealing effect.

Sealing performance detection:

In the petrochemical industry, regular testing of the sealing performance of GLAND PACKING is an important measure to ensure the safe operation of the pipeline.

By using leak detection instruments or observing whether there are signs of leakage at the pipeline joints, potential leakage problems can be discovered and repaired in time.

Maintenance and replacement:

Due to the special environment of the petrochemical industry, GLAND PACKING may be worn or damaged, so it needs to be maintained and replaced regularly.

By regularly checking the status of GLAND PACKING and replacing it as needed, it can be ensured that the sealing performance of the pipeline joints is always kept in the condition.

GLAND PACKING can ensure the stable and reliable sealing performance of the pipeline joints in the petrochemical industry through its multi-layered braided structure, high-quality material selection, easy installation and adjustment characteristics, and regular sealing performance testing and maintenance and replacement measures. This is of great significance for preventing leakage and ensuring production safety.

Eng

Eng  русский

русский