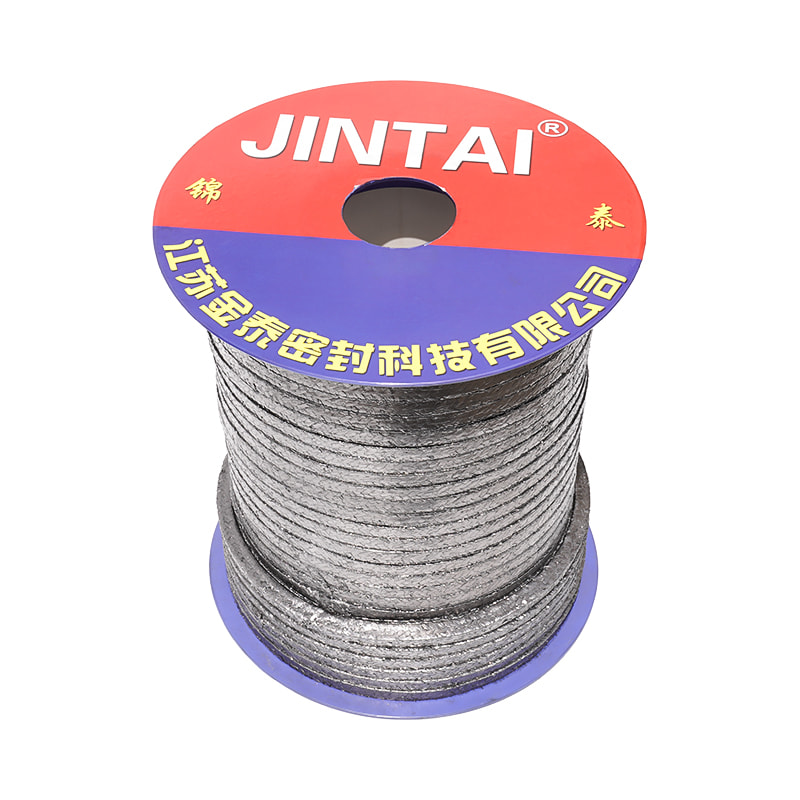

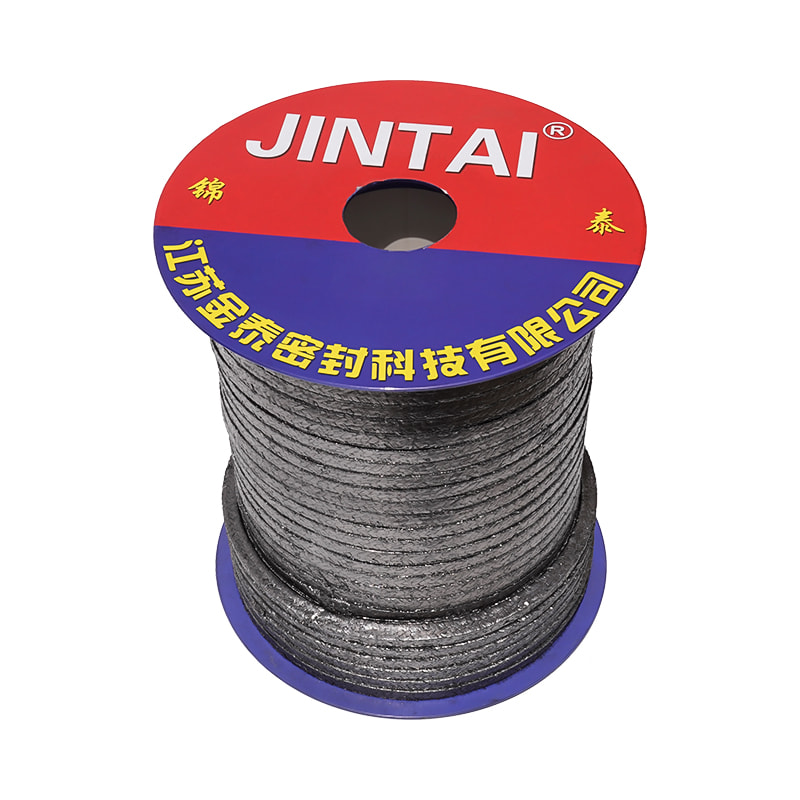

Pure Graphite Braided Gland Packing For Valves Pupm

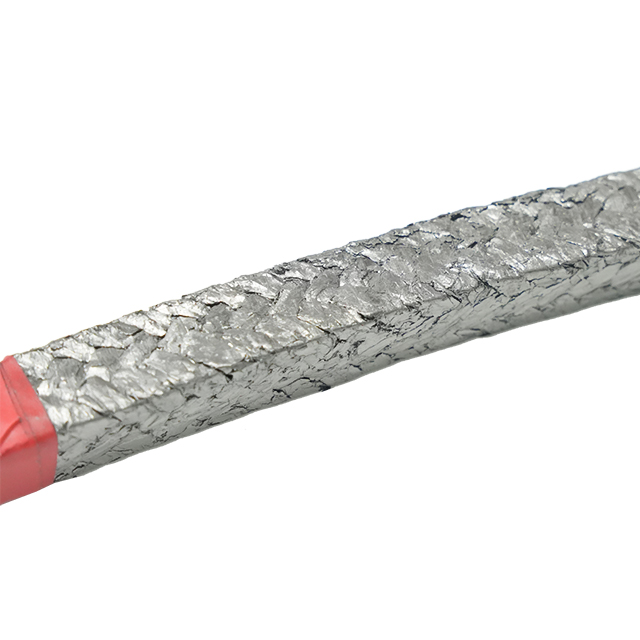

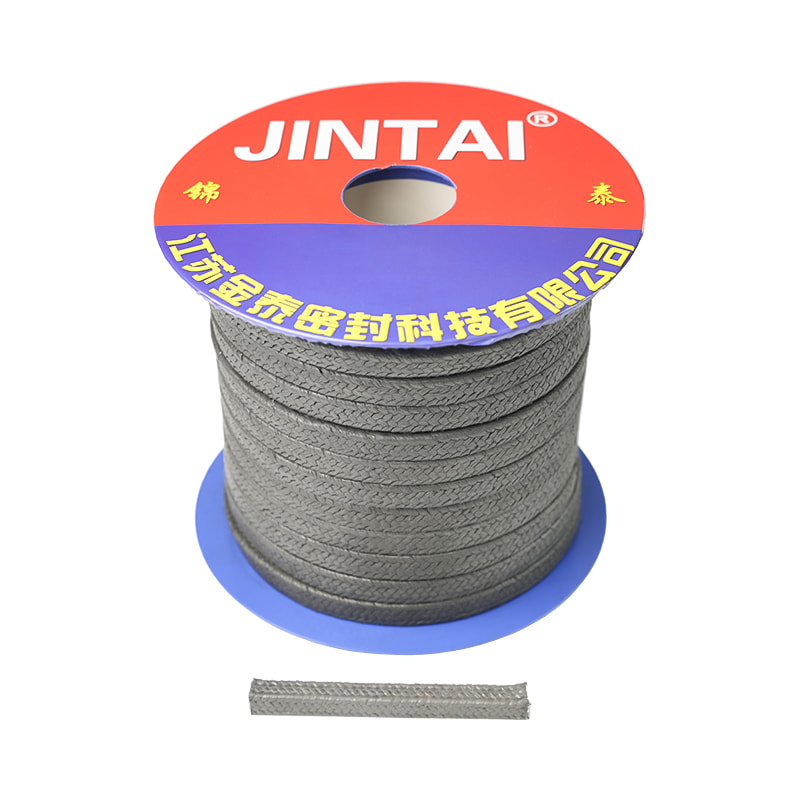

Pure Graphite Braided Gland Packing For Valves and Pumps adopts pure graphite braiding technology, which has high temperature resistance, corrosion resistance and thermal conductivity, and can provide long-term and reliable sealing effect in extreme working environments. Pure Graphite Braided Gland Packing is suitable for various industrial fields, especially high-demand industries such as petroleum, chemical, metallurgy, and electricity. Pure Graphite Braided Gland Packing provides reliable sealing effect for steam, hot water, oil, and chemical media, effectively preventing leakage.

Pure Graphite Braided Gland Packing For Valves & Pumps - Engineered for Reliable Sealing Performance

Product Features

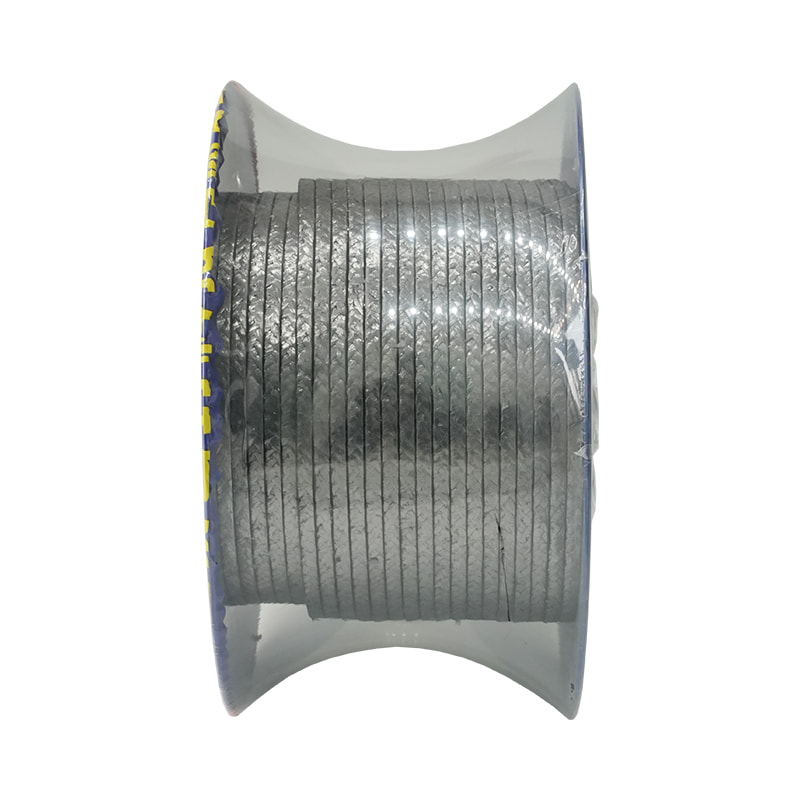

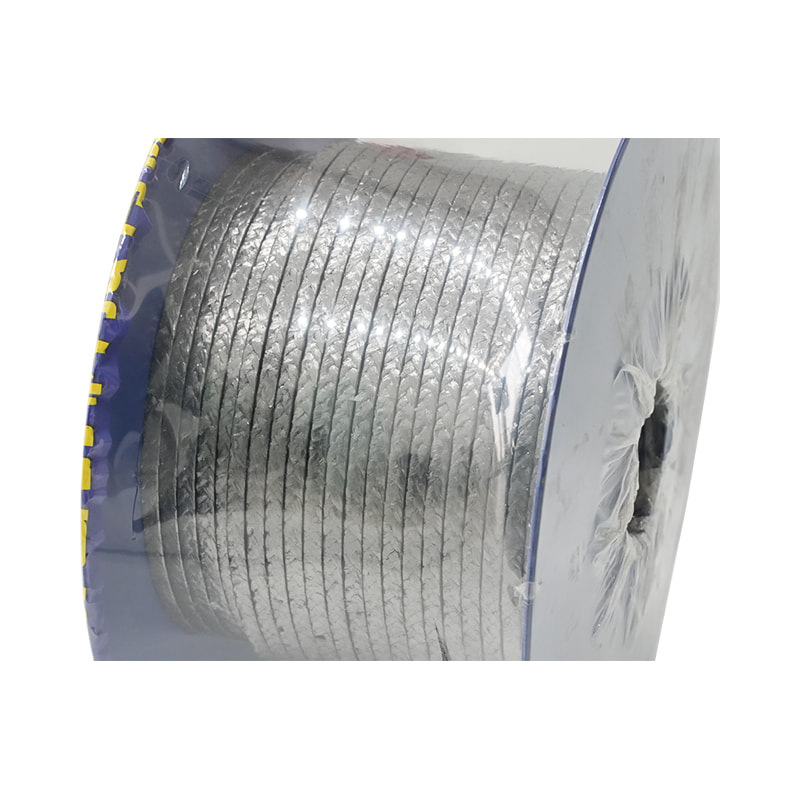

- Material Composition: Constructed from high-purity graphite fibers braided into a uniform structure to maintain dimensional stability under thermal and chemical stress.

- Temperature and Pressure Resistance: Capable of withstanding continuous temperatures up to 550°C and pressures up to 35 bar, suitable for demanding industrial environments.

- Chemical Compatibility: Resistant to a wide range of chemicals, including acids, alkalis, and solvents, ensuring consistent sealing in diverse process applications.

Product Description

The Pure Graphite Braided Gland Packing is designed to provide consistent sealing for valves and pumps across chemical, petrochemical, and power generation industries. Its braided graphite construction allows for low-friction operation while maintaining a tight seal under fluctuating temperatures and pressures.

Manufactured according to international sealing standards, the packing undergoes precise quality control to ensure uniform density and braid integrity. Its material properties contribute to reduced gland wear, lower maintenance frequency, and reliable long-term performance in continuous operation environments.

Applications

This packing is suitable for industrial scenarios requiring reliable sealing under extreme conditions:

- Rotary and reciprocating pumps handling aggressive chemical media

- Gate, globe, and ball valves in power generation plants

- Petrochemical process lines with high-temperature fluid transport

FAQ

What is the optimal gland compression for Pure Graphite Braided Packing?

The recommended initial gland compression is approximately 10–15% of the packing cross-sectional height. This ensures effective sealing while minimizing friction and wear on the shaft or valve stem.

Can this packing be used in steam applications?

Yes, the graphite braid is suitable for saturated and superheated steam service due to its high-temperature tolerance and chemical inertness. Continuous operation up to 550°C is supported.

How often should the packing be inspected or replaced?

Inspection frequency depends on operating conditions, but routine visual checks are advised every 3–6 months for moderate service and monthly for aggressive chemical or high-pressure applications. Replacement should occur when leakage increases or wear compromises sealing performance.

Specifications

|

Pressure |

25.00mpa (Only suitable for valves and other static parts) |

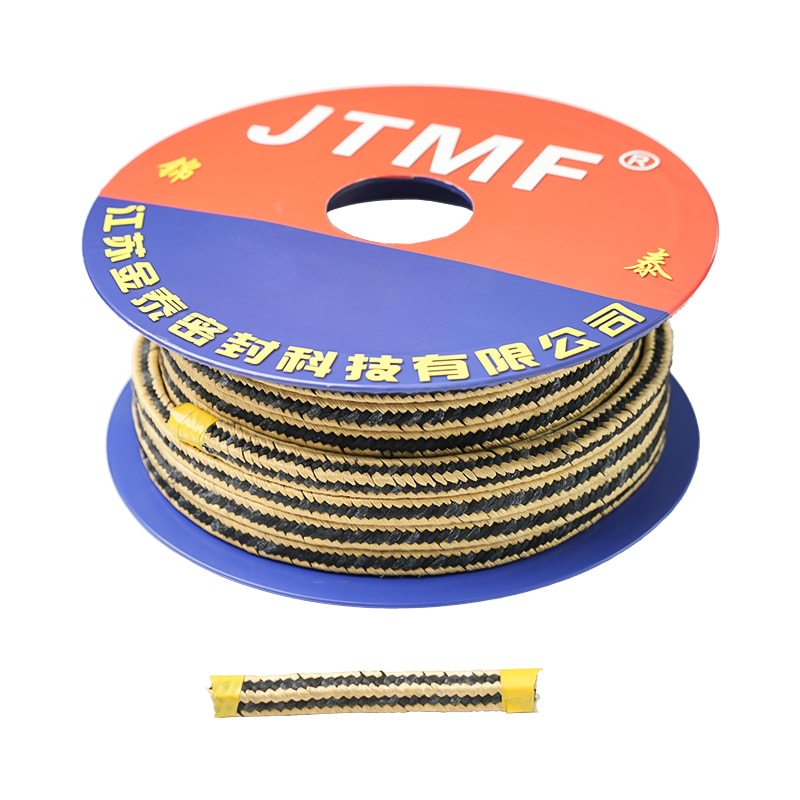

Graphite packing Contains carbon fiber, stainless steel wire, copper wire, inclined wire reinforcement |

|

35mpa (Only suitable for valves and other static parts) |

Inconickel wire outer graphite packing base graphite packing |

|

|

40mpa(Only suitable for valves and other static parts) |

|

|

|

Temperature |

-200℃-+650℃(Steam) |

-200℃-+566℃(Atmosphere) |

|

FH Value: |

0-14 Except for strong oxidants |

|

|

Available cross-section sizes |

≥1/8''~≤3''(3x3-75x75mm) |

|

|

Density |

1.10-1.35gcm² |

(Cotton yarn, fiberglass, SS304 Inconickel wire reinforcement) |

|

1.50-1.60g0m |

(Inconel wire graphite packing) |

|

|

Note: Cotton yarn, glass fiber, carbon fiber, stainless steel wire, copper wire, and Inconel wire reinforced graphite packing can be provided upon request. Inconel wire graphite packing and graphite shoulder disc packing (with adhesive backing) can be provided. |

||

KEEP IN TOUCH

-

In high-utility power generation, the integrity of a steam turbine relies heavily on the performance of its static sealing interfaces. A metal gasket ring is often the first line of defense against ca...

READ MORE -

In the demanding landscape of industrial fluid handling, maintaining seal integrity in high-temperature environments is a paramount challenge for engineers. As centrifugal pumps and valves operate und...

READ MORE -

In high-pressure and high-temperature industrial environments, achieving a hermetic seal is paramount for operational safety and environmental compliance. The corrugated graphite gasket has emerged as...

READ MORE

Pure graphite stuffing box: the green revolution in sealing technology

In the rapidly developing industrial field, sealing technology is a key link to ensure the stable operation of equipment and prevent medium leakage. Its importance is self-evident. Since its establishment in 2004, the sealing technology company located in Xingyuan Road, Yuanzhu Industrial Park, Taixing City, Jiangsu Province has become a leader in the field of domestic sealing technology with its outstanding R&D strength, strict quality management system and forward-looking market layout. Among them, the pure graphite stuffing box, as the company's star product, has won wide acclaim in the market for its excellent sealing performance, environmental protection characteristics and wide application fields.

As an important part of high-end sealing solutions, the pure graphite stuffing box is made of high-purity graphite materials. Graphite, one of the softest minerals in nature, has shown extraordinary hard power in the field of sealing. Its excellent high temperature resistance, corrosion resistance, self-lubrication and good compression rebound performance enable the pure graphite stuffing box to maintain a stable sealing effect under extreme working conditions, effectively extending the service life of the equipment and reducing maintenance costs.

Relying on a strong scientific research team and advanced production equipment, the company continuously optimizes the formula and manufacturing process of the pure graphite stuffing box to ensure that its product performance reaches the international advanced level. By precisely controlling the particle size distribution of graphite and adding appropriate amounts of reinforcing agents and lubricants, the stuffing box can maintain high sealing performance while also having good anti-scouring and anti-wear capabilities, and can adapt to the sealing needs under various complex working conditions.

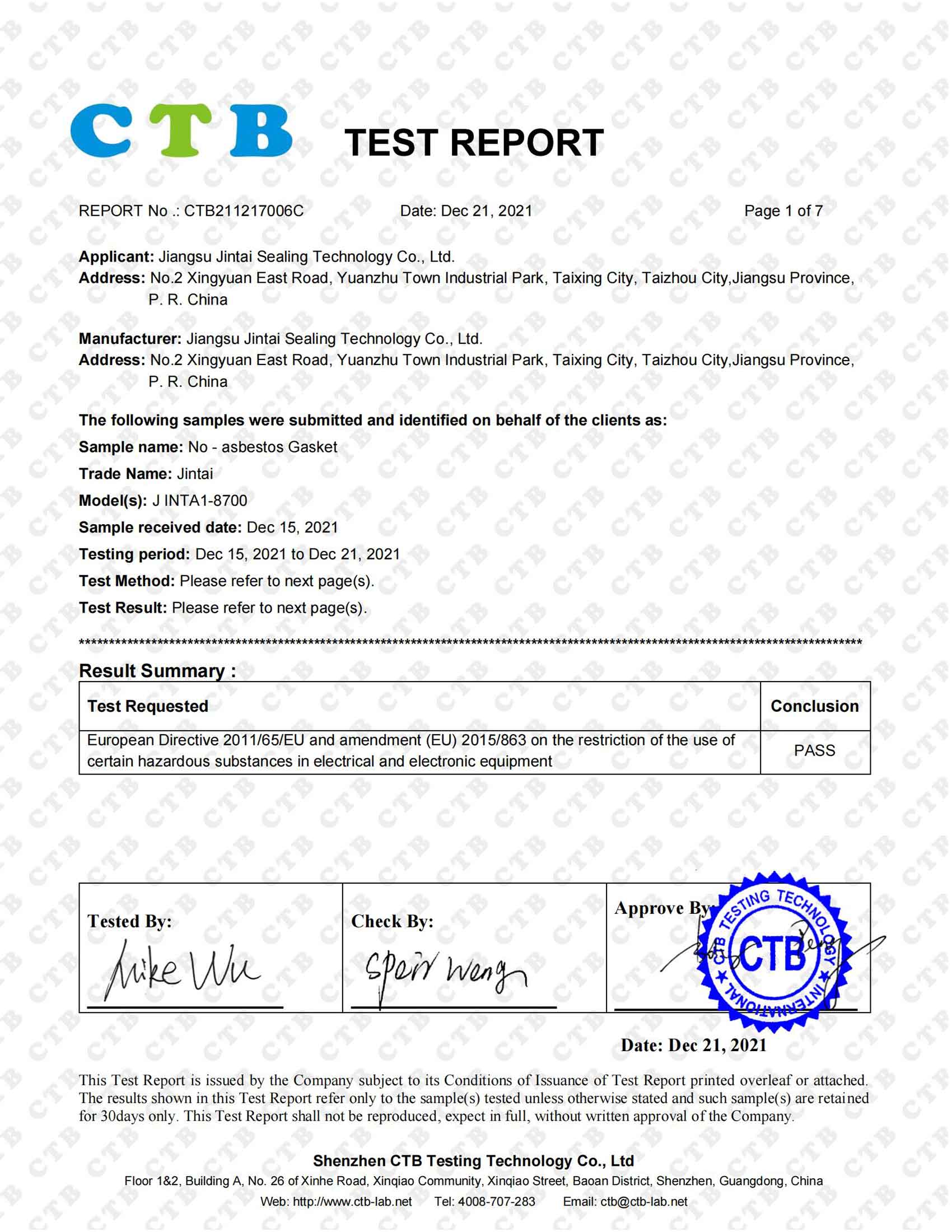

In the current context of global advocacy of green development, the company actively responds to national environmental protection policies and is committed to developing environmentally friendly sealing products. Pure graphite stuffing boxes, as asbestos-free and non-toxic environmentally friendly sealing materials, not only meet international environmental standards, but also greatly reduce potential harm to the environment and human body. This move not only reflects the company's sense of social responsibility, but also sets an example for promoting the green transformation of the entire sealing industry.

Pure graphite stuffing boxes have been widely used in many industries such as shipping, power, steel, chemical industry, and machinery due to their excellent performance and wide applicability. In the shipping industry, it can effectively prevent the erosion of equipment by media such as seawater and oil, and ensure the stable operation of the ship's power system; in the power industry, it has become the preferred material for high-pressure, high-temperature pipelines and valve sealing, ensuring the safety and reliability of power transmission; in the chemical industry, its corrosion resistance has become an ideal choice for equipment that handles corrosive media.

In the face of increasingly fierce market competition and changing customer needs, the company has always adhered to the innovation-driven development strategy, continuously increased R&D investment, and expanded product application areas. In the future, the company will continue to deepen cooperation with major industries, launch more high-performance sealing products that meet market demand, and actively explore the application of new materials and new technologies in the sealing field, contributing to the advancement of sealing technology in China and even the world.

Eng

Eng  русский

русский