How does METAL GASKET prevent damage to equipment by corrosive media?

2024.06.06

2024.06.06

Industry News

Industry News

In the chemical industry, how does METAL GASKET prevent damage to equipment by corrosive media?

In the chemical industry, METAL GASKET plays an important role in preventing damage to equipment by corrosive media through its high temperature resistance and corrosion resistance. The following is a specific explanation of how METAL GASKET prevents damage to equipment by corrosive media:

Material selection:

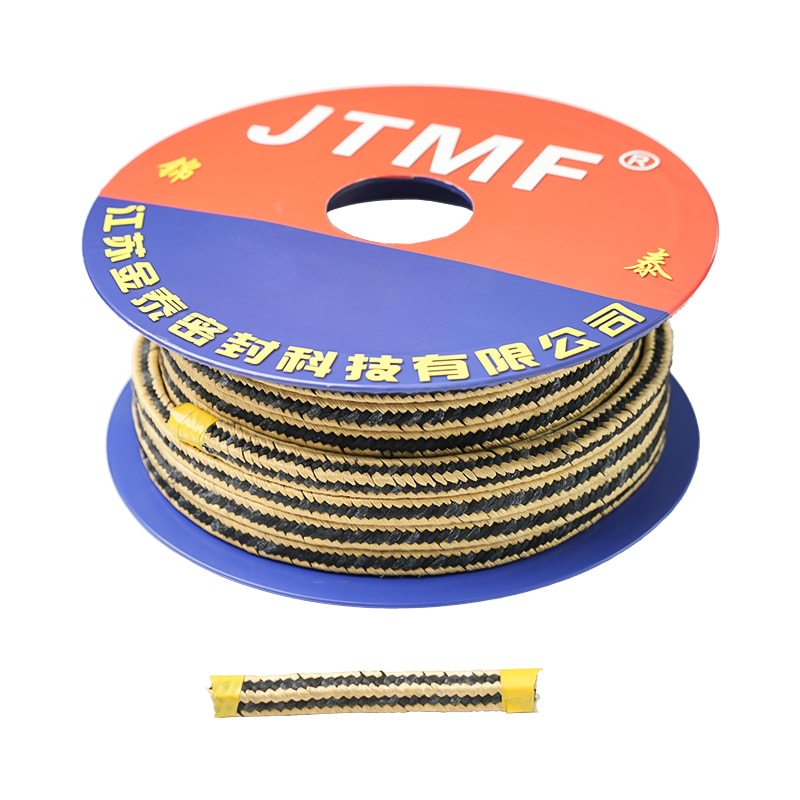

METAL GASKET is usually made of corrosion-resistant materials, such as stainless steel, carbon steel and other alloy materials. These materials can maintain stable performance in various corrosive media and are not easily corroded.

Multi-layer structure:

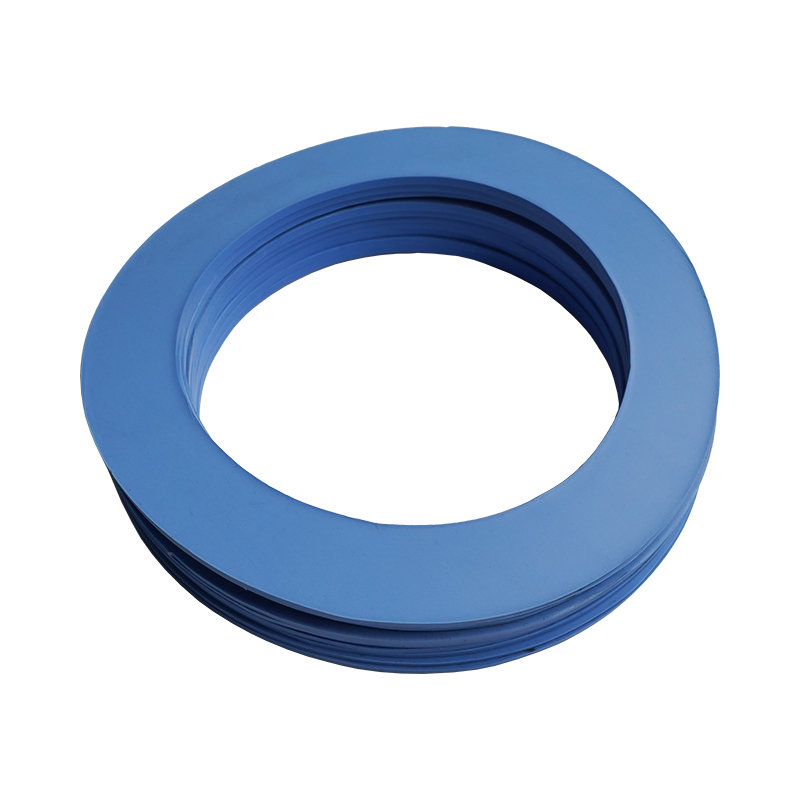

METAL GASKET may adopt a multi-layer structure, and each layer is specially treated to enhance its corrosion resistance. The multi-layer structure can more effectively isolate the corrosive medium and prevent it from penetrating into the interior of the equipment.

Sealing performance:

METAL GASKET has sealing performance, which can ensure the tightness of the equipment connection and prevent the corrosive medium from leaking into the equipment through the gap. This helps to keep the inside of the equipment clean and intact and extend the service life of the equipment.

High temperature resistance:

In the chemical industry, many corrosive media become more active and destructive at high temperatures. The high temperature resistance of METAL GASKET enables it to maintain stable performance in high temperature environments and continue to play a role in sealing and corrosion prevention.

Maintenance and replacement:

Regularly checking the status of METAL GASKET and replacing it when necessary is an important measure to prevent corrosive media from damaging equipment. Timely replacement of damaged or aged METAL GASKET can ensure that the sealing performance and corrosion resistance of the equipment are continuously guaranteed.

In summary, METAL GASKET effectively prevents corrosive media from damaging equipment in the chemical industry through its corrosion-resistant material selection, multi-layer structure, sealing performance, high temperature resistance, and regular maintenance and replacement. These characteristics make METAL GASKET one of the indispensable sealing components in the chemical industry.

Eng

Eng  русский

русский