Graphite Gland Packing: The Core of High-Temperature Sealing and Fluid Control

2025.09.04

2025.09.04

Industry News

Industry News

- 1 The Importance and Applications of Graphite Gland Packing

- 2 What is Flexible Graphite Packing?

- 3 Key Technologies of Graphite Packing Seals

- 4 Graphite Gland Packing Price and Cost-Benefit Analysis

- 5 High-Temperature Packing Material Selection and Challenges

- 6

- 7 Pump Packing Selection Guide

- 8 Prospects for the Future Development of Graphite Gland Packing

- 9

- 10 Frequently Asked Questions (FAQ)

The Importance and Applications of Graphite Gland Packing

Graphite Gland Packing is an indispensable sealing material in modern industry. Made from highly purified flexible graphite fibers, it offers excellent resistance to high temperatures, high pressures, and chemical corrosion, along with self-lubricating properties. It is these unique characteristics that make it an irreplaceable choice for extreme operating conditions.

Why is Graphite Gland Packing So Important?

1. Excellent Temperature Resistance:

Graphite Gland Packing operates stably across a wide temperature range. It can withstand continuous high temperatures up to 450°C in an oxidative environment, and its temperature limit can reach up to 1200°C in non-oxidative environments. This makes it an excellent performer for sealing applications in high-temperature valves and pumps in industries such as steel, petrochemicals, and power generation.

2. Strong Pressure and Corrosion Resistance:

In addition to temperature resistance, Graphite Gland Packing can also withstand high pressures, with a pressure resistance range of up to 25 MPa. Due to the stable chemical structure of graphite, it effectively resists the erosion of most acids, alkalis, and organic solvents (with the exception of strong oxidizing acids), ensuring long-term effective sealing in harsh chemical environments.

3. Self-Lubricating Properties:

Graphite Gland Packing has good self-lubricating properties, which significantly reduces friction with the shaft or valve stem, lowers torque, minimizes wear, and thus extends the service life of equipment while reducing maintenance costs.

Overview of Graphite Gland Packing Applications

Graphite Gland Packing is widely used in various critical industrial equipment to prevent fluid or gas leakage, ensuring production safety and efficiency.

| Application Scenario | Typical Equipment | Reason for Use |

| Petrochemical Industry | Pumps, valves, reactors | Addresses sealing challenges of high-temperature, high-pressure, and corrosive chemical media. |

| Power Generation Industry | Thermal power units, nuclear power plants | Sealing for steam valves and feedwater pumps, resistant to high-temperature and high-pressure steam. |

| Steel and Metallurgy | Blast furnaces, continuous casting equipment | Seals high-temperature gases and liquids, and resists thermal shock. |

| Paper Industry | Pumps, mixers | Resists abrasive media and corrosive fluids. |

In these applications, Graphite Gland Packing effectively prevents the leakage of harmful gases (such as steam, flue gas) and liquids (such as corrosive acids, oils), protecting the environment, ensuring employee safety, and guaranteeing stable equipment operation. It is not just a simple sealing material but a core guarantee of fluid control and industrial safety.

What is Flexible Graphite Packing?

Flexible Graphite Packing, as an advanced sealing material, is a crucial member of the Graphite Gland Packing family. Its core advantage lies in its unique material structure and exceptional flexibility, which allow it to provide reliable sealing in various demanding industrial environments.

Materials and Structure of Flexible Graphite Packing

Unlike traditional braided fiber packing, Flexible Graphite Packing is primarily made from highly purified flexible graphite foil. These graphite foils are processed through special braiding or winding techniques to form a high-density packing structure. This material and process give it several key characteristics:

- High-purity Graphite: Typically, the graphite purity is above 99%, which ensures it remains chemically stable at high temperatures and maintains consistent physical properties.

- Flexibility: "Flexible" is its most significant feature. This allows the packing to better conform to the minor irregularities of the shaft or valve stem surface, creating a tighter and more effective seal.

- High Density: The special braiding or winding method results in a density far greater than that of ordinary fiber packing, effectively reducing media permeation and improving sealing performance.

Performance Advantages of Flexible Graphite Packing

Flexible Graphite Packing is widely used in high-temperature, high-pressure, and highly corrosive conditions due to its significant performance advantages. Here is a parameter comparison with traditional asbestos packing:

| Performance Parameter | Flexible Graphite Packing | Asbestos Packing (largely phased out) |

| Max. Service Temperature | ~450°C in oxidative environments, up to 1200°C in non-oxidative environments | ~250°C |

| Chemical Resistance | Excellent resistance to most acids, alkalis, and organic solvents | Poor resistance to strong acids and alkalis |

| Self-Lubrication | Excellent, reduces friction and wear, extends equipment life | Poor, requires additional lubricants |

| Thermal Conductivity | Good, effectively dissipates heat, protecting the shaft and stuffing box | Poor, can easily trap heat |

| Flexibility & Compressibility | Excellent, easy to install, conforms to uneven surfaces | Poor, tends to harden after installation, affecting the sealing effect |

| Health and Safety | Non-toxic, harmless to humans | Contains carcinogenic asbestos, harmful to health |

Flexible Graphite Packing, with its outstanding thermal stability, chemical resistance, and self-lubricating properties, provides an excellent sealing solution for valves, pumps, and various static equipment. It not only withstands extreme working environments but also brings long-term economic benefits to industrial production by reducing equipment wear and maintenance costs.

Key Technologies of Graphite Packing Seals

Graphite Packing Seals are a crucial technology in industrial fluid control. They use the compression characteristics of Graphite Gland Packing within the equipment's stuffing box to create an effective seal, preventing fluid or gas leakage. To achieve a reliable and long-lasting seal, mastering the following key technical points is essential.

1. Working Principle: Compression and Plastic Deformation

The core working principle of a Graphite Packing Seal is to use external pressure, such as the bolts of the packing gland, to radially compress the Graphite Gland Packing inside the stuffing box. Due to the unique plasticity of graphite, the packing expands inward and outward under the compression force, tightly adhering to the surface of the equipment's shaft or valve stem and the inner wall of the stuffing box.

- Radial Expansion: The compression force causes the Graphite Gland Packing to expand inward, filling the tiny gap between the shaft and the stuffing box.

- Axial Compression: The packing is tightly compressed, forming a solid sealing ring that effectively blocks fluid leakage.

2. Key Factors Affecting Sealing Performance

The performance of a Graphite Packing Seal is not only determined by the material; installation and operational parameters are also critical.

- Pre-tightening Force: The pre-tightening force applied to the packing gland is the first step in creating an effective seal. Too little force will not allow the packing to expand sufficiently, leading to leakage. Too much force will increase friction, causing wear on the shaft or valve stem and potentially damaging the packing itself.

- Installation Method: Correct installation is key to success. Graphite Gland Packing is usually cut into rings with a 45-degree diagonal cut and pressed into the stuffing box one ring at a time. Each ring must fit snugly without gaps to ensure the integrity of the seal.

- Equipment Precision: The surface finish and concentricity of the equipment's shaft or valve stem have a direct impact on the sealing effect. The smoother the surface, the lower the friction and the better the sealing performance.

3. Common Failures and Troubleshooting

Although Graphite Packing Seals are very reliable, some common issues can still arise in practical applications.

| Common Problem | Possible Cause | Solution |

| Leakage | Insufficient pre-tightening force, improper installation, worn packing | Properly increase the pre-tightening force, reinstall the packing correctly, or replace with new Graphite Gland Packing |

| Packing Overheating | Excessive pre-tightening force, high friction, insufficient cooling | Properly loosen the pre-tightening bolts, check and improve the cooling system |

| Stem or Shaft Wear | Excessive packing pre-tightening force, or improper selection | Re-adjust the pre-tightening force, or select a Graphite Gland Packing product with a lower friction coefficient |

By mastering these key technologies, you can maximize the advantages of Graphite Gland Packing Seals and ensure the long-term, efficient, and safe operation of industrial equipment.

Graphite Gland Packing Price and Cost-Benefit Analysis

The Graphite Gland Packing Price is not the only criterion for purchasing decisions. In industrial applications, the focus should shift from the initial procurement cost to the long-term comprehensive cost-effectiveness. A seemingly expensive Graphite Gland Packing product can offer a higher overall cost-benefit if it leads to a longer service life, fewer maintenance cycles, and greater equipment efficiency.

Key Factors Affecting the Price of Graphite Gland Packing

The pricing of Graphite Gland Packing is influenced by multiple factors, which directly determine its performance and reliability:

- Graphite Purity: Graphite purity is a core factor determining the performance of Graphite Gland Packing. High-purity graphite (typically >99% purity) has better temperature and chemical corrosion resistance, but its production cost is also higher.

- Braiding Process and Structure: Complex braiding processes, such as multi-strand diagonal braiding, can provide higher density and better structural stability, thereby improving sealing performance and service life, but this increases manufacturing costs.

- Size and Specifications: The price of Graphite Gland Packing varies with different sizes and cross-sectional shapes. For example, packing used for large pumps or valves requires more material, so the price is naturally higher.

- Reinforcing Materials: Some Graphite Gland Packing products are enhanced with reinforcing materials like carbon fibers or stainless steel wires to improve their compression and anti-extrusion capabilities. These reinforcing materials directly impact the final product price.

Cost-Benefit Analysis of Graphite Gland Packing

When evaluating the value of Graphite Gland Packing, we should not just look at the initial price but conduct a comprehensive cost-benefit analysis. Here is a parameter comparison between high-quality Graphite Gland Packing and low-cost alternatives over long-term use:

| Parameter | High-quality Graphite Gland Packing | Low-cost Graphite Gland Packing or Alternative |

| Initial Procurement Cost | Higher | Lower |

| Service Life | Long (can last for years) | Short (typically a few months) |

| Maintenance Frequency | Low | High |

| Equipment Downtime | Minimal | Frequent |

| Friction and Energy Consumption | Lower (good self-lubricating properties) | Higher (high friction, requires more power) |

| Safety and Leakage Risk | Very low (reliable seal) | Higher (prone to leakage, poses safety risks) |

| Overall Cost | Lower (initial cost + low maintenance + low energy consumption) | Higher (initial cost + high maintenance + high downtime loss) |

As the table shows, while the initial investment in high-quality Graphite Gland Packing is higher, its long-term benefits are clear. By reducing equipment downtime, maintenance costs, and energy consumption, its overall cost over the product's life cycle is far lower than that of cheap but unstable products.

Therefore, when selecting Graphite Gland Packing for critical equipment, investing in a high-quality product is not only a wise economic decision but also an important measure to ensure production safety and efficiency.

High-Temperature Packing Material Selection and Challenges

In industrial production, many pieces of equipment must operate at extremely high temperatures, which places stringent demands on sealing materials. The selection of a suitable High-temperature Packing Material is crucial, as it directly impacts equipment safety, stable operation, and maintenance costs. Among various high-temperature sealing materials, Graphite Gland Packing stands out due to its unique properties, but its application also faces certain challenges.

Criteria for Selecting High-Temperature Packing Materials

When selecting a High-temperature Packing Material, several key factors must be considered:

- Temperature Resistance: This is the most basic requirement. The packing material must maintain its physical and chemical stability at the actual working temperature without decomposition, hardening, or melting.

- Pressure Resistance: High-temperature conditions are often accompanied by high pressure, so the packing must have excellent resistance to extrusion and pressure.

- Corrosion Resistance: High-temperature fluids are often corrosive. The chosen packing material must be able to resist chemical attack from the working medium.

- Thermal Conductivity: Good thermal conductivity helps dissipate heat from the friction area, preventing local overheating and protecting both the shaft and the packing itself.

- Self-Lubrication: In high-temperature environments, external lubricants can easily fail. Packing with good self-lubricating properties effectively reduces friction, lowering torque and wear.

Comparison of Graphite Gland Packing with Other High-Temperature Materials

Graphite Gland Packing performs exceptionally well against these criteria. Here is a comparison with some traditional high-temperature sealing materials:

| Parameter | Flexible Graphite Packing | PTFE Packing | Aramid (Kevlar) Packing |

| Max. Service Temperature | ~450°C in oxidative environments, up to 1200°C in non-oxidative environments | ~260°C | ~280°C |

| Chemical Resistance | Excellent resistance to most acids, alkalis, and solvents, but can be corroded by strong oxidizing acids | Very strong resistance to almost all chemical media | Good resistance to most chemical media |

| Thermal Conductivity | Excellent | Poor | Poor |

| Self-Lubrication | Excellent | Good | Poor, high friction coefficient |

| Application Limitations | Should be avoided in strong oxidative environments | Limited to low-to-medium pressure and low-to-medium speed applications | Can be abrasive to the shaft, requires a high-hardness shaft |

Challenges and Solutions

Although Graphite Gland Packing is an ideal High-temperature Packing Material, it also faces challenges in practical applications:

- Strong Oxidative Environments: In high-temperature, high-pressure, and strongly oxidative media (such as certain concentrated nitric or chromic acids), the graphite material can oxidize, affecting the sealing performance.

- Solution: For such conditions, a Graphite Gland Packing with added anti-oxidant agents can be used, or an enhanced type with higher chemical resistance, such as carbon fiber or stainless steel wire reinforced packing.

- Installation and Compression Force: Incorrect installation and excessive compression force can damage the structure of the Graphite Gland Packing, leading to seal failure or equipment wear.

- Solution: Follow the manufacturer's instructions for installation and use a torque wrench to control the compression force, ensuring it stays within the recommended range.

By thoroughly understanding these challenges and adopting corresponding solutions, you can fully leverage the superior performance of Graphite Gland Packing and ensure the long-term, reliable operation of equipment in extreme high-temperature environments.

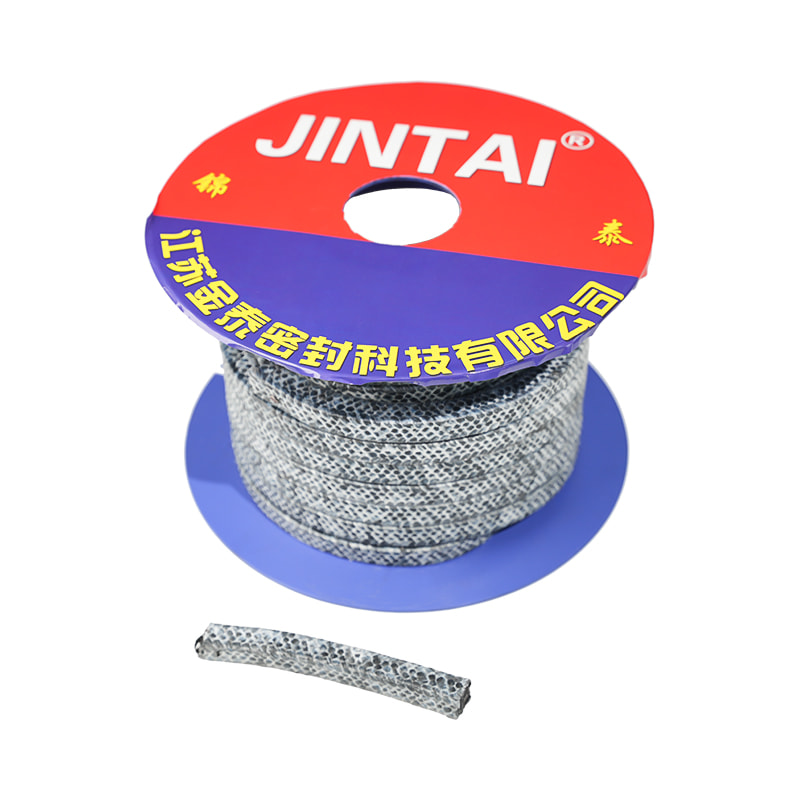

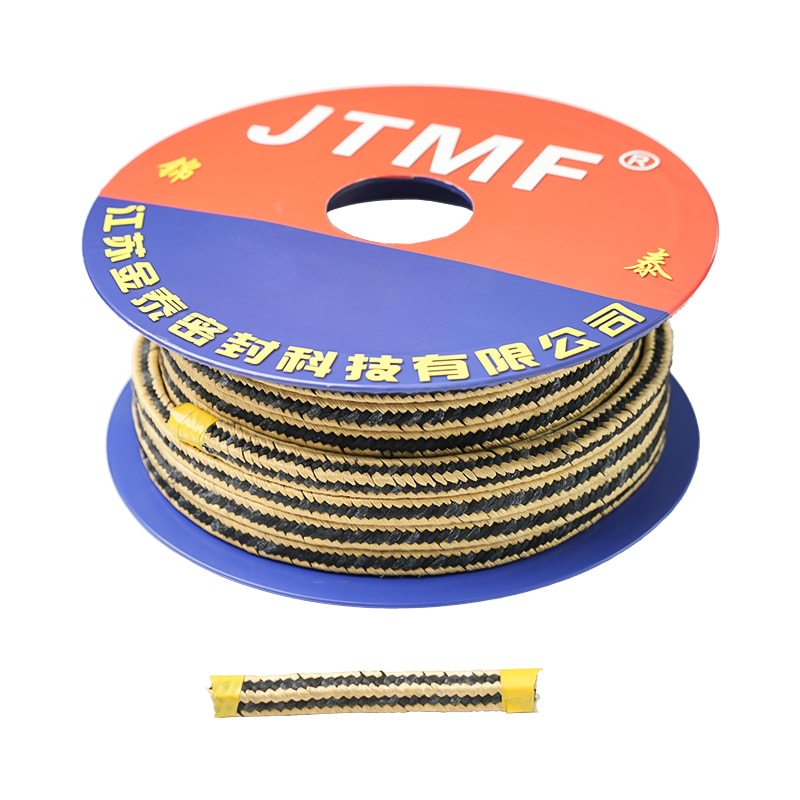

Fire Pump Valve Packing Glands Carbon Fiber Graphite Gland Packing

Pump Packing Selection Guide

Choosing the right packing for a pump is crucial for ensuring its efficient and safe operation. The correct Pump Packing Selection can significantly reduce leakage, lower energy consumption, and extend equipment life. And Graphite Gland Packing, with its superior performance, plays a vital role in the field of pump sealing. This guide provides professional advice on how to select the right Graphite Gland Packing for different operating conditions.

1. Determine the Pump's Operating Conditions

Before selecting Graphite Gland Packing, you must have a comprehensive understanding of the pump's working environment. Here are a few key parameters to consider:

- Fluid Medium: Is it water, oil, chemicals, or slurry? This determines the packing's corrosion and abrasion resistance.

- Temperature: The temperature range of the medium, especially the maximum temperature. This directly affects the packing's temperature resistance.

- Pressure: The internal pressure of the pump. The packing must be able to withstand it without being extruded.

- Shaft Speed: The rotational speed of the pump shaft. High-speed operation generates more heat, requiring better thermal conductivity and self-lubricating properties from the packing.

2. Types of Graphite Gland Packing and Application Selection

Based on different working conditions, Graphite Gland Packing can have various reinforced structures to meet specific needs.

| Packing Type | Structural Features | Suitable Conditions | Advantages |

| Pure Flexible Graphite Packing | Braided from pure flexible graphite foil, no reinforcing materials. | High-temperature, high-pressure, low-to-medium speed pumps, suitable for most fluid media (except strong oxidizing acids). | Excellent temperature resistance and self-lubricating properties, very low friction coefficient, and no wear on the shaft. |

| Stainless Steel Wire Reinforced Graphite Packing | Stainless steel wire is added to the graphite braid for reinforcement. | High-pressure, high-speed pumps, or conditions requiring higher mechanical strength. | Extremely high resistance to extrusion and pressure, effectively resists high-pressure shock and prevents packing deformation. |

| Carbon Fiber Reinforced Graphite Packing | Carbon fiber is added to the graphite, typically for corner reinforcement. | Conditions requiring both high temperature/pressure and higher wear resistance and structural strength, especially for fluids containing particles. | Combines the self-lubrication of graphite with the wear resistance and strength of carbon fiber, offering balanced performance. |

3. Solutions for Common Pump Packing Problems

In practice, various issues can be encountered. Here are some recommendations for common problems:

- Leakage Issues: If the leakage is excessive, it may be due to insufficient packing pre-tightening force or improper installation. You should gradually tighten the gland bolts and observe the leakage rate until it reaches an acceptable range. If leakage persists, the packing may be worn or the wrong type was selected.

- Overheating Issues: Packing overheating is usually caused by excessive pre-tightening force or high friction between the shaft and the packing. You can properly loosen the gland bolts or consider using a Graphite Gland Packing with better self-lubricating properties. For high-speed pumps, a good cooling system is essential.

- Wear Issues: Shaft wear may be caused by improper packing selection (e.g., using packing with a high friction coefficient) or the presence of hard impurities in the packing. In this case, re-evaluate the working conditions and choose a more shaft-friendly pure flexible Graphite Gland Packing or a properly flushed carbon fiber-reinforced type.

By gaining a deep understanding of pump operating parameters and the performance characteristics of Graphite Gland Packing, you can make a professional Pump Packing Selection, thereby ensuring the efficient, reliable, and economical operation of your equipment.

Prospects for the Future Development of Graphite Gland Packing

As a mature sealing technology, Graphite Gland Packing is not stagnant. With the growing industrial demand for higher performance, greater environmental friendliness, and more intelligence, Graphite Gland Packing is evolving in several key directions. These trends will not only enhance its performance in traditional fields but also open up new application areas.

1. Integration of New Composite Materials and Nanotechnology

Future Graphite Gland Packing will no longer be a single graphite material. It will integrate more advanced composite materials and nanotechnology to address current application pain points.

- Nano-enhanced Graphite Packing: By embedding nanomaterials like carbon nanotubes or graphene into the graphite matrix, the mechanical strength, wear resistance, and thermal conductivity of the packing can be significantly improved. This will allow the packing to perform better under higher pressure and speed conditions.

- Smart Composite Packing: By incorporating micro-sensors, future Graphite Gland Packing can monitor its own wear, temperature, and leakage in real-time. This data can be transmitted to a control center via the Internet of Things (IoT) technology, enabling predictive maintenance and shifting from reactive to proactive management.

2. Environmental Protection and Sustainable Development

With increasingly strict global environmental regulations, the future development of Graphite Gland Packing will focus more on its environmental performance throughout its life cycle.

- Halogen-free and Low-emission Formulas: Future Graphite Gland Packing will be produced using stricter processes to ensure it does not contain halogens or other harmful substances, preventing the generation of toxic gases upon high-temperature decomposition.

- Recyclable and Reusable: Research will be dedicated to developing recyclable Graphite Gland Packing products to reduce waste's environmental impact. This aligns with the concept of a circular economy and can also lower long-term operating costs.

3. Further Breakthroughs in Performance Parameters

Through the application of new materials and processes, the极限 parameters of future Graphite Gland Packing will be further enhanced. Here is a comparison of future achievable performance parameters with current mainstream products:

| Performance Parameter | Current Mainstream Graphite Packing | Future Enhanced Graphite Packing |

| Max. Service Temp. (non-oxidative) | ~1200°C | >1500°C |

| Max. Working Pressure | ~25 MPa | >40 MPa |

| Friction Coefficient | ~0.15 | <0.1 |

| Self-Lubrication Performance | Excellent | Extremely Excellent |

| Service Life | Relatively long | Longer and more predictable |

In summary, the future development of Graphite Gland Packing will focus on innovation in material science, the integration of smart technologies, and higher environmental standards. These advancements will make its performance in extreme conditions more outstanding, while providing the industry with safer, more efficient, and more sustainable sealing solutions.

Frequently Asked Questions (FAQ)

1. Why choose graphite gland packing as a high-temperature sealing solution?

Graphite gland packing is a top choice for high-temperature sealing due to its superior performance. It can withstand non-oxidative high temperatures up to 1200°C and has excellent resistance to high pressure and chemical corrosion. Its inherent self-lubricating properties significantly reduce friction and wear, extending equipment life. Our company, Jiangsu Jintai Sealing Technology Co., Ltd., through our high-end brand Nofstein, specializes in providing high-quality sealing solutions. We use advanced materials and manufacturing processes to ensure our graphite gland packing products meet the sealing needs of various industries under harsh high-temperature conditions, ensuring equipment safety and stable operation.

2. How can I ensure optimal performance and service life for graphite packing seals?

To achieve the best sealing effect, correct installation and selection are crucial. First, you must choose the appropriate type of graphite gland packing based on the pump's operating conditions (such as the fluid medium, temperature, pressure, and shaft speed). During installation, ensure the pre-tightening force is appropriate to avoid overheating and wear from excessive tightness. Jiangsu Jintai Sealing Technology Co., Ltd. is a large-scale comprehensive sealing technology enterprise. We not only research and manufacture various types of sealing products but also have a complete quality management and monitoring system. Our products have passed multiple rigorous tests and we partner with internationally renowned brands like Garlock and Flexitallic to provide you with professional selection advice and technical support, ensuring your graphite gland packing sealing system performs at its best.

3. What are the unique advantages of the graphite gland packing products from Jiangsu Jintai Sealing Technology Co., Ltd.?

As a professional company founded in 2004, Jiangsu Jintai Sealing Technology Co., Ltd. is dedicated to the research and production of high-quality sealing products. Our Nofstein brand focuses on technological innovation, continuously developing new sealing materials to meet market demands. Our graphite gland packing products not only resist high temperature and pressure but also have excellent self-lubricating and thermal conductivity properties, effectively reducing equipment operating energy consumption and maintenance costs. Our products have received CCS classification society quality system identification, passed the CiT environmental protection test and multiple national non-metal tests, proving their outstanding quality and reliability. With years of industry experience and technical expertise, we provide a complete set of sealing solutions for various industries, including shipping, power, iron and steel, and chemicals.

Eng

Eng  русский

русский