Comparison of Graphite Gland Packing and PTFE Packing: Performance, Cost, and Application Scenarios

2025.09.12

2025.09.12

Industry News

Industry News

- 1 Introduction

- 2 Performance Comparison

- 3 Cost Analysis

- 4 Application Scenarios

- 5

- 6 FAQ

- 6.1 What is the primary difference between graphite and PTFE gland packing?

- 6.2 Which gland packing material is more cost-effective?

- 6.3 Can PTFE gland packing handle high temperatures?

- 6.4 Is graphite gland packing suitable for all chemicals?

- 6.5 Which gland packing is better for high-speed applications?

Introduction

In industrial sealing applications, choosing the right gland packing material is crucial for ensuring equipment efficiency and longevity. Two commonly used materials are graphite gland packing and PTFE gland packing. Each offers distinct advantages and is suited for specific operational conditions. This article delves into a detailed comparison of these materials, focusing on their performance, cost-effectiveness, and ideal application scenarios.

Performance Comparison

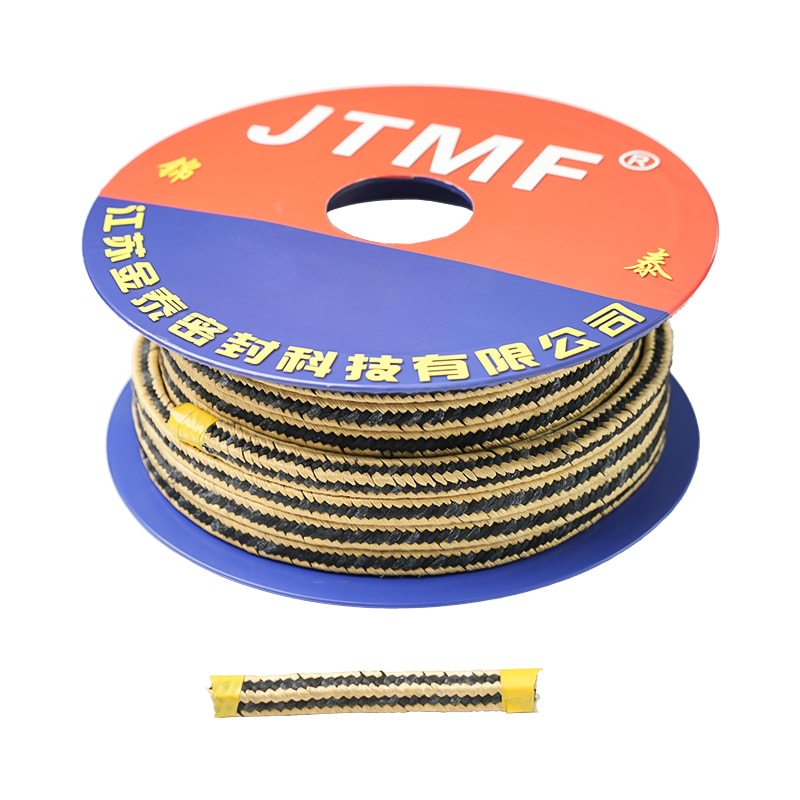

Graphite Gland Packing

Graphite gland packing is renowned for its high-temperature resistance and chemical inertness. It performs exceptionally well in dynamic sealing applications, especially in centrifugal pumps handling water, petroleum derivatives, and various chemicals under high-speed and high-pressure conditions. Its self-lubricating properties and dimensional stability make it a reliable choice for long-term operations.

- High Temperature Resistance: Effective in temperatures up to 450°C.

- Chemical Resistance: Resistant to a wide range of chemicals, except strong oxidizers.

- Self-Lubricating: Reduces friction, enhancing sealing efficiency.

- Dimensional Stability: Maintains shape under varying operational conditions.

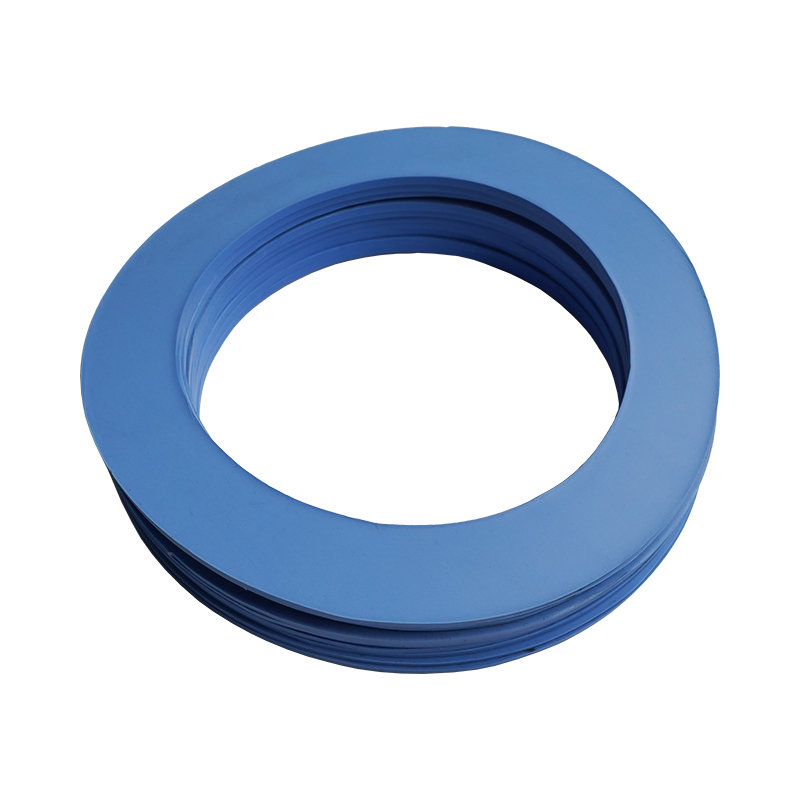

PTFE Gland Packing

PTFE gland packing, made from polytetrafluoroethylene, is known for its exceptional chemical resistance and low friction properties. It is suitable for applications involving aggressive chemicals and varying temperatures, especially in sensitive or non-contaminating environments. PTFE's versatility makes it widely applicable across diverse industrial setups.

- Chemical Resistance: Excellent resistance to most chemicals.

- Temperature Tolerance: Operates effectively in a wide temperature range.

- Low Friction: Minimizes wear and energy consumption.

- Non-Reactive: Ideal for sensitive applications where contamination is a concern.

Performance Comparison Table

| Feature | Graphite Gland Packing | PTFE Gland Packing |

| Temperature Resistance | Up to 450°C | Wide range |

| Chemical Resistance | Limited | Excellent |

| Self-Lubricating | Yes | Yes |

| Dimensional Stability | High | Moderate |

| Cost | Moderate | Higher |

Cost Analysis

When evaluating gland packing materials, cost is a significant factor. Graphite gland packing typically offers a balance between performance and cost, making it a cost-effective choice for many applications. PTFE gland packing, while offering superior chemical resistance and versatility, generally comes at a higher price point. However, its longevity and reduced maintenance needs can offset the initial investment over time.

Cost Comparison Table

| Material | Initial Cost | Maintenance Cost | Longevity | Overall Cost-Effectiveness |

| Graphite Gland Packing | Moderate | Low | High | High |

| PTFE Gland Packing | High | Low | Very High | Moderate |

Application Scenarios

Graphite Gland Packing Applications

Graphite gland packing is ideal for high-temperature, high-speed, and chemically demanding environments. Its self-lubricating property and dimensional stability make it suitable for pumps, valves, and rotary equipment across diverse industrial processes.

- High-Temperature Environments: Such as steam systems and high-temperature pumps.

- Chemical Processing: Handling a wide range of chemicals, excluding strong oxidizers.

- High-Speed Machinery: Where self-lubrication and dimensional stability are crucial.

PTFE Gland Packing Applications

PTFE gland packing is versatile for corrosive chemical handling, food, and pharmaceutical industries. Its non-reactive nature makes it ideal for applications requiring contamination-free operation, while maintaining flexibility across various temperatures.

- Corrosive Chemical Handling: Especially where graphite may not be compatible.

- Food and Pharmaceutical Industries: Due to its non-reactive nature.

- Low-Temperature Systems: Where materials need to maintain flexibility.

Valves Pump Gland Packing Seals White Pure PTFE Gland Packing

FAQ

What is the primary difference between graphite and PTFE gland packing?

The main difference lies in their chemical resistance and temperature tolerance. Graphite packing excels in high-temperature applications but has limited chemical resistance. PTFE packing offers excellent chemical resistance and operates effectively across a wide temperature range.

Which gland packing material is more cost-effective?

Graphite gland packing generally presents a more cost-effective solution due to its moderate initial cost and low maintenance requirements. PTFE gland packing, while more expensive initially, may offer cost savings in applications requiring high chemical resistance and reduced maintenance.

Can PTFE gland packing handle high temperatures?

PTFE gland packing can handle a wide range of temperatures; however, it may not be suitable for extremely high-temperature applications where graphite packing would perform better.

Is graphite gland packing suitable for all chemicals?

Graphite gland packing is resistant to many chemicals but should not be used with strong oxidizers. PTFE packing offers broader chemical resistance, making it suitable for more aggressive chemicals.

Which gland packing is better for high-speed applications?

Graphite gland packing is better suited for high-speed applications due to its self-lubricating properties and dimensional stability. PTFE packing can also be used but may wear faster under high-speed conditions.

Eng

Eng  русский

русский