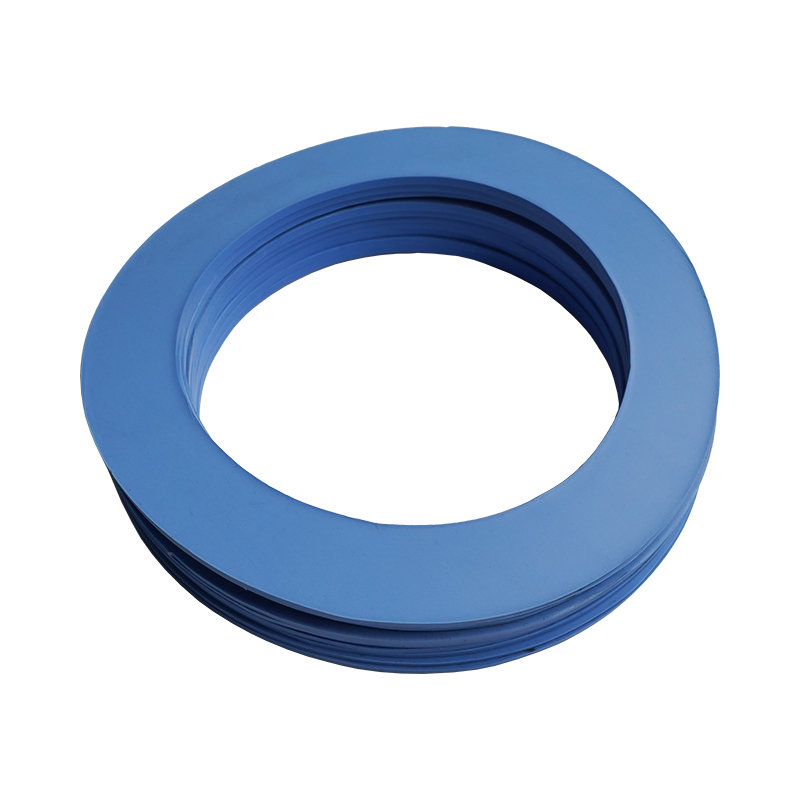

Soft Expanded Modified PTFE Sheet With Graphite, PTFE Teflon Sealing

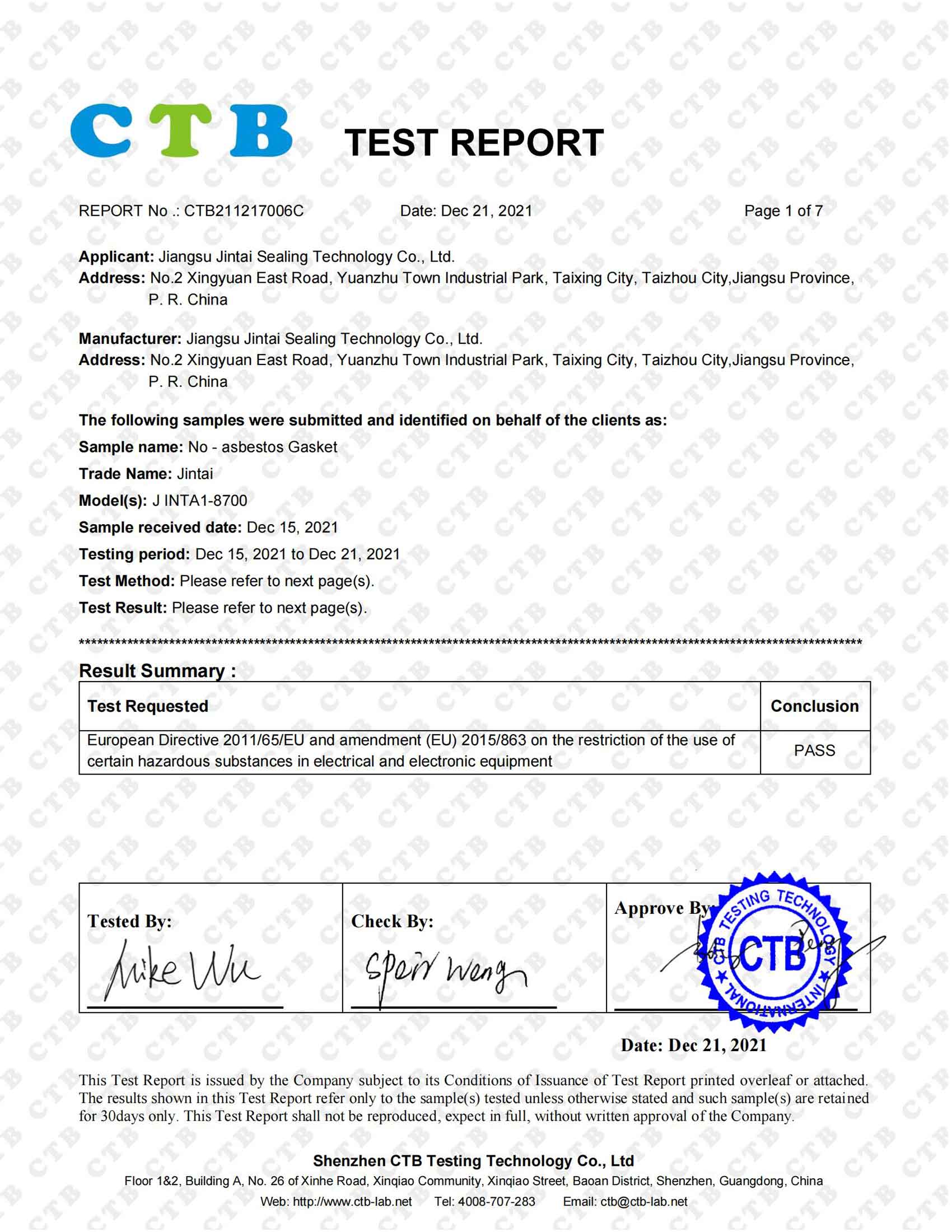

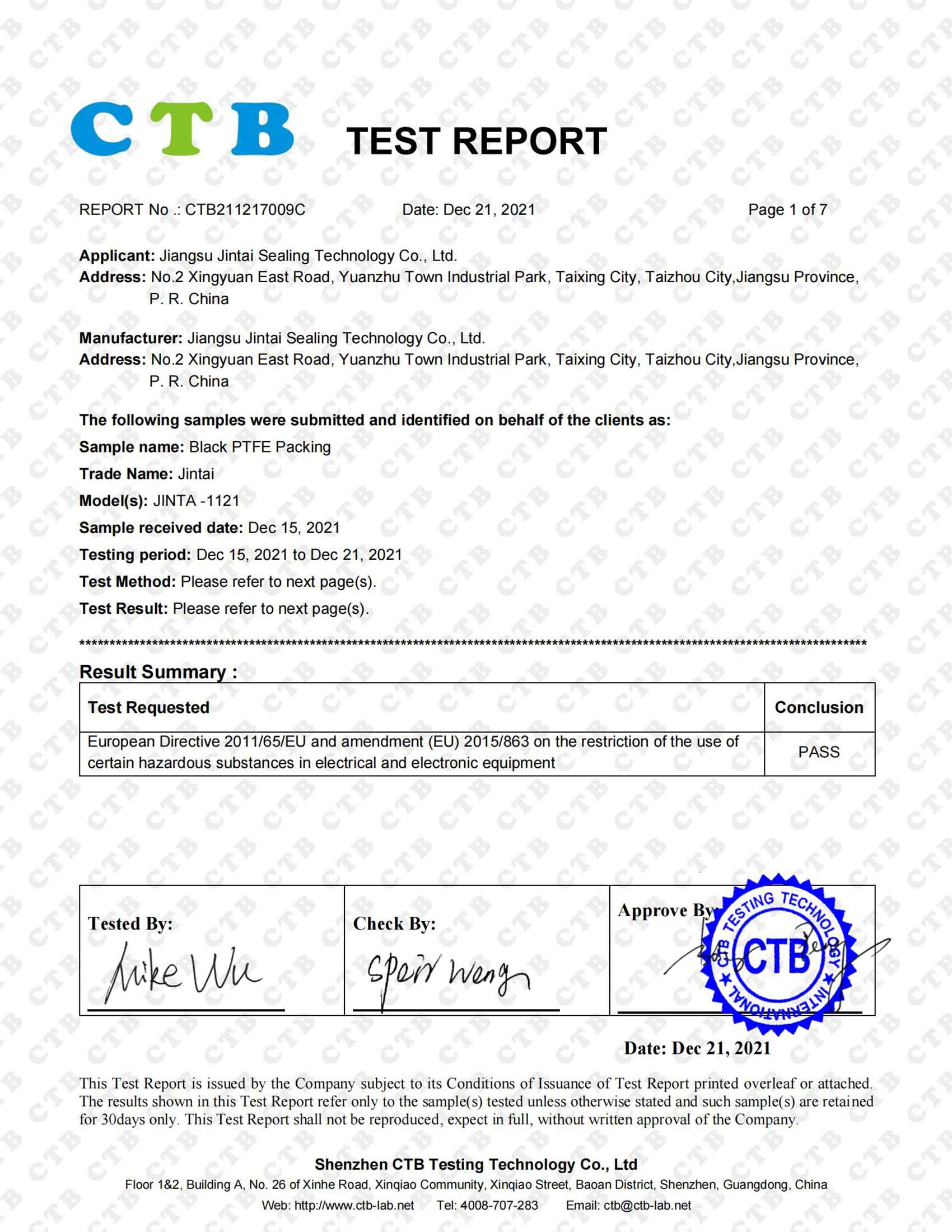

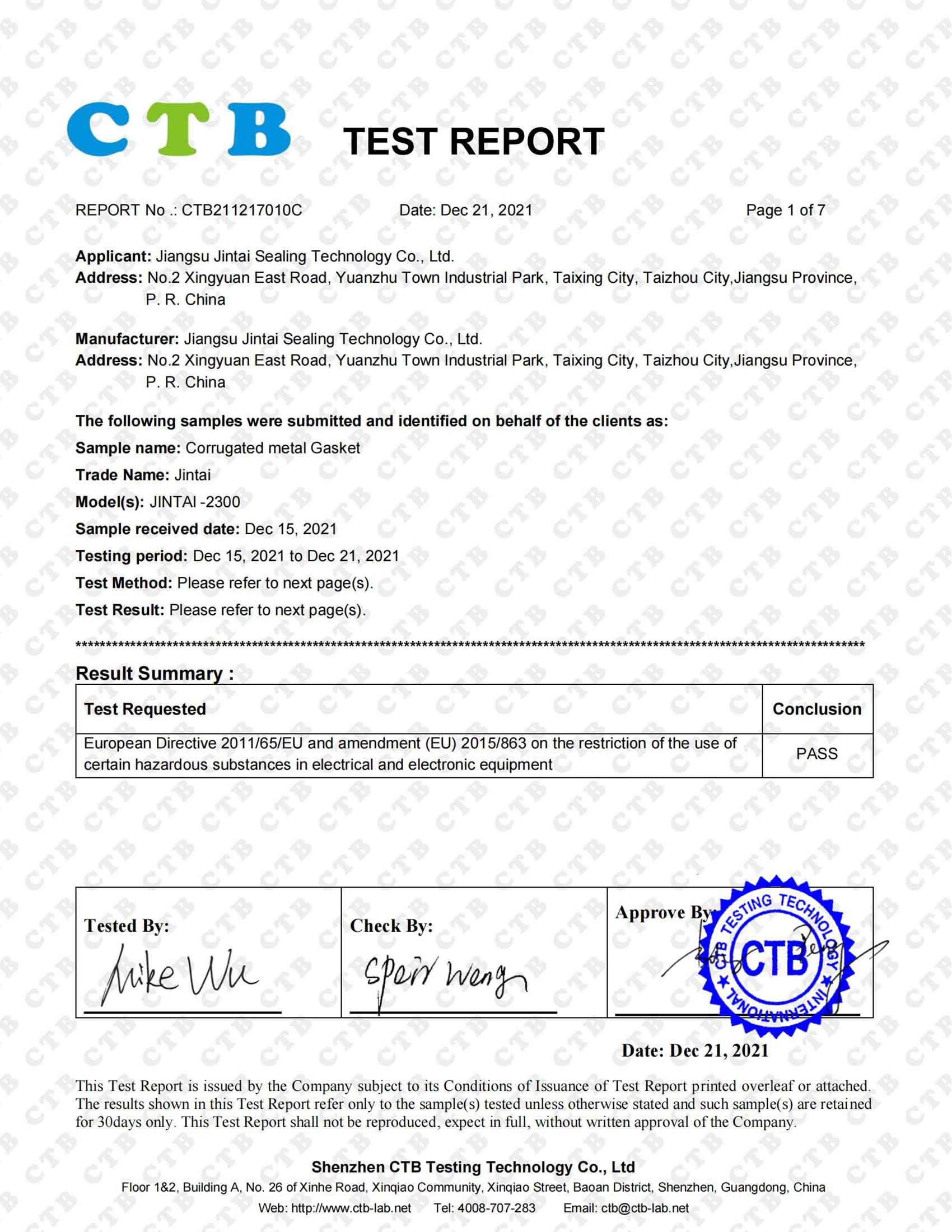

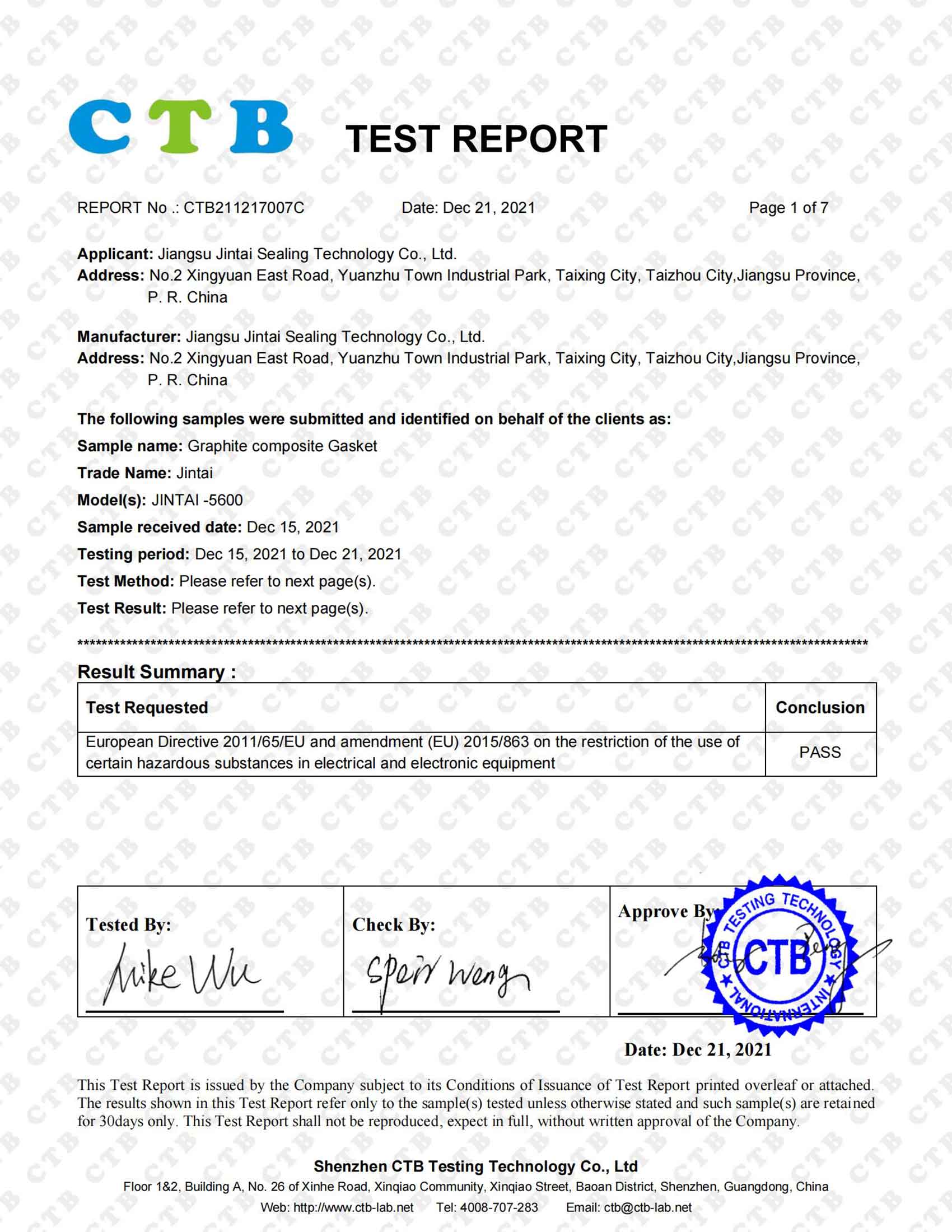

Soft Expanded Modified PTFE Sheet With Graphite is made of pure polytetrafluoroethylene (PTFE) modified with graphite. It has excellent chemical resistance, high temperature resistance and low friction coefficient, and can maintain stable performance in extreme temperature ranges from -190℃ to 260℃. The product is corrosion-resistant, aging-resistant and non-sticky, and is suitable for harsh environments such as strong acids, strong alkalis and organic solvents. The addition of graphite further enhances the thermal conductivity and compressive resistance of the material, making it perform well under high temperature and high pressure conditions. It is widely used in chemical, pharmaceutical, food processing, aerospace and other industries, especially for flange connections, pipe seals and equipment gaskets with extremely high sealing requirements. It complies with FDA and RoHS standards.

High-Performance Graphite-Infused Expanded PTFE Sheet for Superior Sealing

Our Soft Expanded Modified PTFE Sheet with Graphite is an advanced sealing solution designed for demanding industrial applications. This innovative material combines the exceptional properties of PTFE with the lubricating benefits of graphite, delivering unmatched performance in high-temperature and corrosive environments.

The graphite-filled expanded PTFE sheet offers superior chemical resistance, excellent compressibility, and outstanding thermal stability. Its unique modified composition enhances creep resistance while maintaining the flexibility required for effective sealing.

- Enhanced Thermal Conductivity: Graphite particles improve heat dissipation

- Reduced Friction: Self-lubricating properties minimize wear

- Chemical Inertness: Resists virtually all industrial chemicals

- Excellent Compression Recovery: Maintains seal integrity under pressure fluctuations

- Temperature Resistance: Performs from -268°C to +315°C (-450°F to +600°F)

| Parameter | Value |

|---|---|

| Material | Modified PTFE with Graphite |

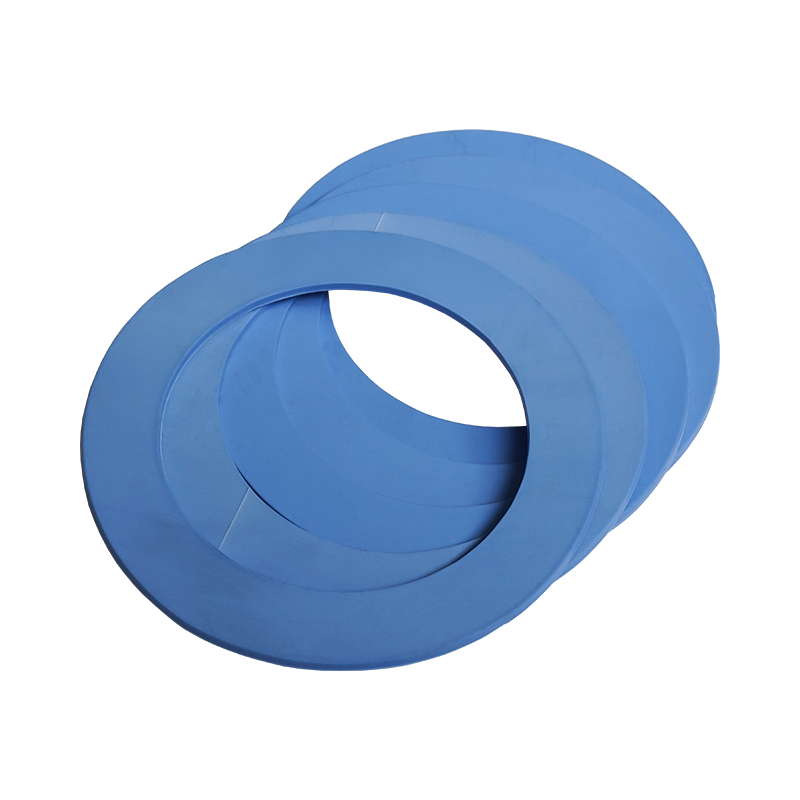

| Thickness Range | 0.5mm to 6.0mm |

| Density | 0.6-1.2 g/cm³ |

| Tensile Strength | 5-15 MPa |

| Compression Set | 15-30% (at room temperature) |

| Thermal Conductivity | 0.35 W/mK |

| Pressure Rating | Up to 200 bar (depending on thickness) |

Our graphite-PTFE composite sheet is ideal for:

- Chemical Processing: Gaskets for pumps, valves, and reactors

- Power Generation: Seals for turbines and heat exchangers

- Oil & Gas: Flange gaskets in refineries and pipelines

- Pharmaceutical: Sanitary gaskets for clean processes

- Food Processing: FDA-compliant sealing solutions

- Automotive: High-temperature engine compartment seals

Why Choose Our Graphite PTFE Sheet?

Compared to standard PTFE sheets, our modified version offers:

- 30% better creep resistance

- Improved load-bearing capacity

- Reduced cold flow characteristics

- Enhanced sealing performance under thermal cycling

- Longer service life in aggressive environments

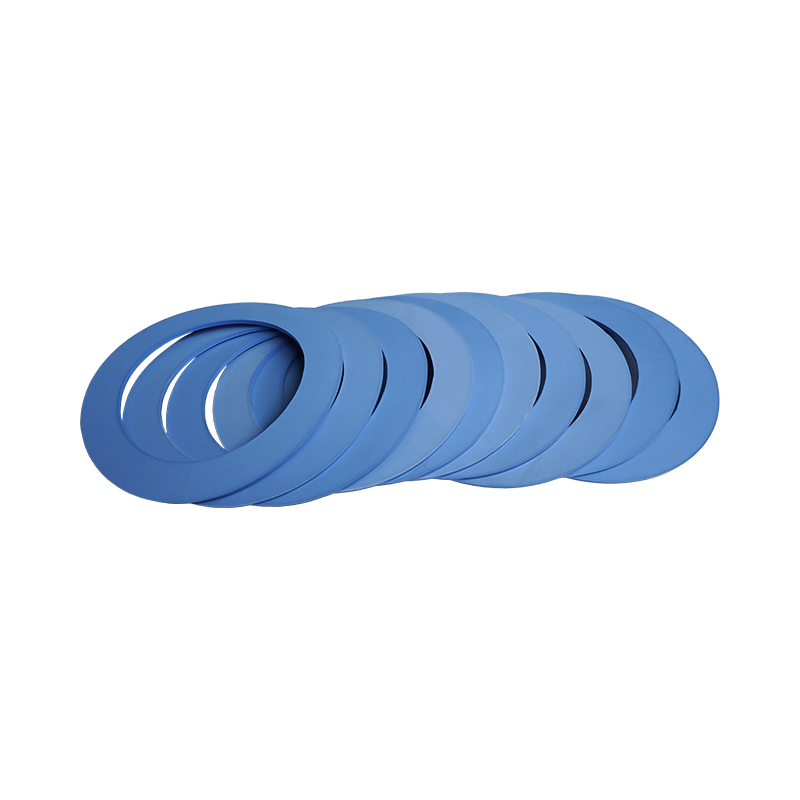

Customization Options

We can provide this material in various forms to meet your specific requirements:

- Custom-cut gaskets and shapes

- Adhesive-backed versions for easy installation

- Special thicknesses outside standard range

- Combination with other materials for multi-layer seals

Specifications

KEEP IN TOUCH

-

In the demanding environments of the chemical, petrochemical, and power industries, selecting the appropriate sealing component is critical for preventing hazardous leaks and ensuring operational long...

READ MORE -

In high-pressure and high-temperature environments, the mechanical performance of a metal gasket ring is the definitive factor in preventing catastrophic system failures. Engineering a reliable seal r...

READ MORE -

In the demanding landscape of industrial fluid handling, the integrity of a sealing system can dictate the operational lifespan of expensive machinery. Selecting the appropriate carbon gland packing i...

READ MORE

Modified polytetrafluoroethylene sheet: a new era of high-performance materials, who can stop the wave of its industrial application?

In the ever-changing industrial field, the progress of materials science is one of the key forces driving the upgrading of the industry. Among them, modified polytetrafluoroethylene sheet (MPTFE), as an outstanding representative of high-performance materials, has shown extraordinary application potential in sealing, corrosion resistance, wear resistance and other fields with its unique physical and chemical properties. Jiangsu Jintai Sealing Technology Co., Ltd. has not only deeply cultivated the traditional sealing material market, but also made remarkable achievements in the research and development and production of modified polytetrafluoroethylene sheets, providing efficient and reliable sealing solutions for many industries such as shipping, electricity, steel, chemical industry, machinery, etc.

Modified polytetrafluoroethylene sheet is an advanced material made by introducing other elements or compounds into traditional polytetrafluoroethylene (PTFE) through a specific process to enhance its certain specific properties. Compared with pure PTFE, MPTFE not only maintains the original low friction coefficient, high chemical stability, excellent heat resistance and cold resistance, but also significantly improves its mechanical strength, wear resistance, creep resistance and dimensional stability, which is more adaptable to the needs of complex and changing industrial environments.

Jiangsu Jintai Sealing Technology Co., Ltd., relying on its deep accumulation in the field of sealing technology for many years, regards the research and development and production of modified polytetrafluoroethylene sheets as one of the important directions of the company's strategic development. The company has an elite team of material scientists, engineers and technicians, dedicated to the formulation optimization, production process improvement and new product development of MPTFE materials. By introducing advanced modification technology and production equipment, Jintai has successfully developed a series of modified polytetrafluoroethylene sheet products with excellent performance and complete specifications, meeting the high standards of sealing materials in different industries.

In the marine environment, the corrosion resistance and sealing of equipment are crucial. Modified polytetrafluoroethylene sheets are widely used in ship engines, pipeline systems, valve seals and other fields with their excellent corrosion resistance and good sealing performance to ensure the safety of ship navigation.

In the heat exchange system, steam pipeline and flue gas treatment system of power equipment, high temperature, high pressure and corrosive media pose severe challenges to sealing materials. MPTFE sheets have become ideal sealing materials in these fields with their excellent high temperature resistance and chemical corrosion resistance.

In the process of steel smelting and chemical production, the medium often has the characteristics of strong corrosiveness, high temperature and high pressure. Modified polytetrafluoroethylene sheets can not only effectively resist these harsh environments, but also provide a long-lasting and stable sealing effect, extending the service life of the equipment.

In precision machinery and automation equipment, there are high requirements for the wear resistance and low friction of parts. The application of MPTFE sheets can significantly reduce mechanical wear, improve equipment operation efficiency, and reduce maintenance costs.

With the continuous advancement of science and technology and the increasing diversification of industrial needs, the market prospects of modified polytetrafluoroethylene sheets will be broader. Jiangsu Jintai Sealing Technology Co., Ltd. will continue to uphold the corporate philosophy of "innovation, quality, and service", increase R&D investment, deepen cooperation with domestic and foreign scientific research institutions, and continuously launch more high-performance and high-value-added modified polytetrafluoroethylene sheet products to contribute to the development of my country's sealing materials industry, and also provide global customers with more high-quality and professional sealing solutions.

Eng

Eng  русский

русский