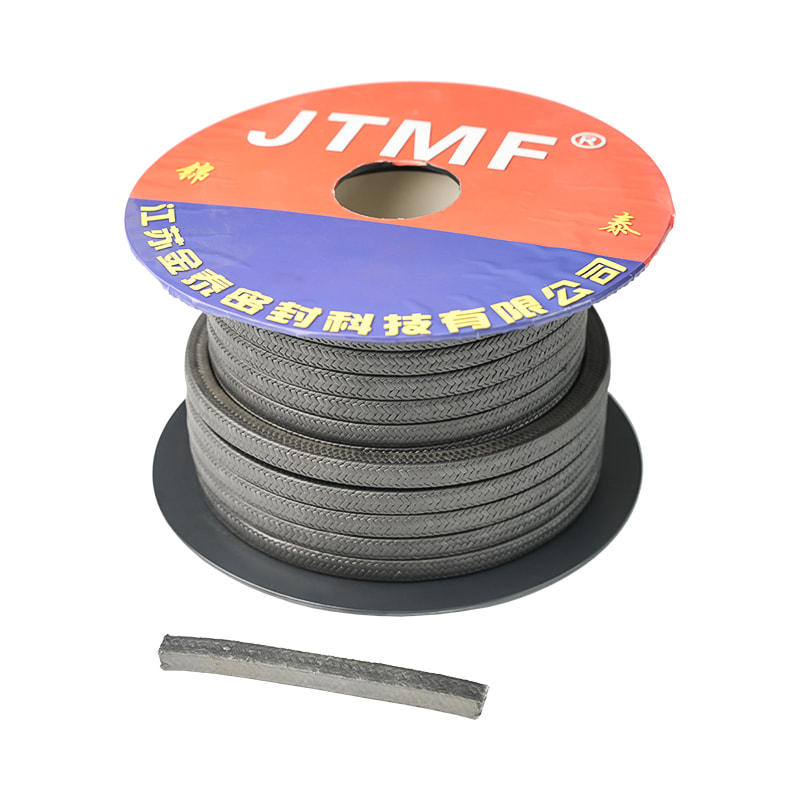

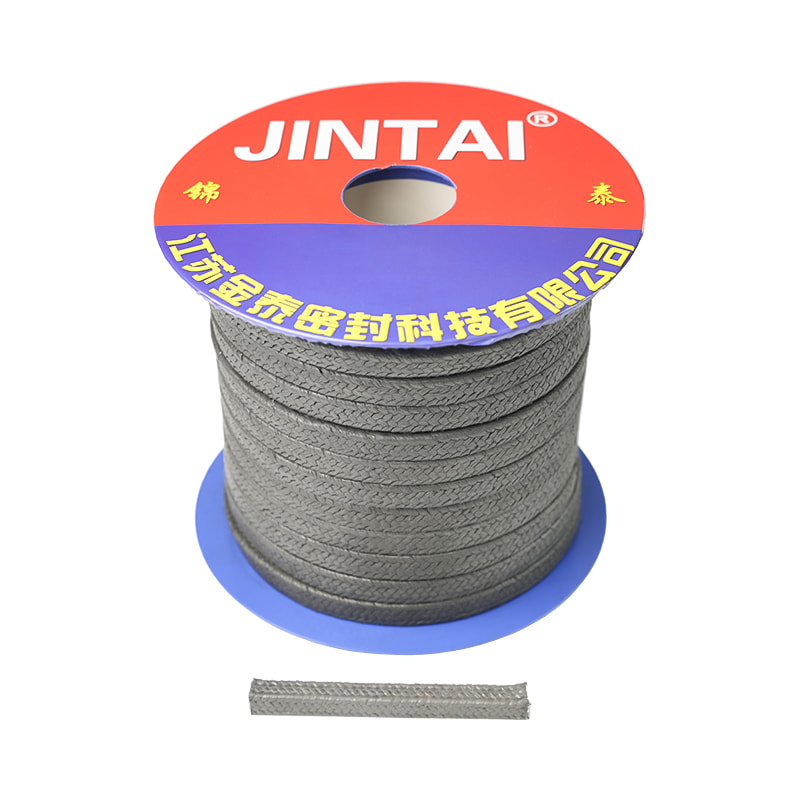

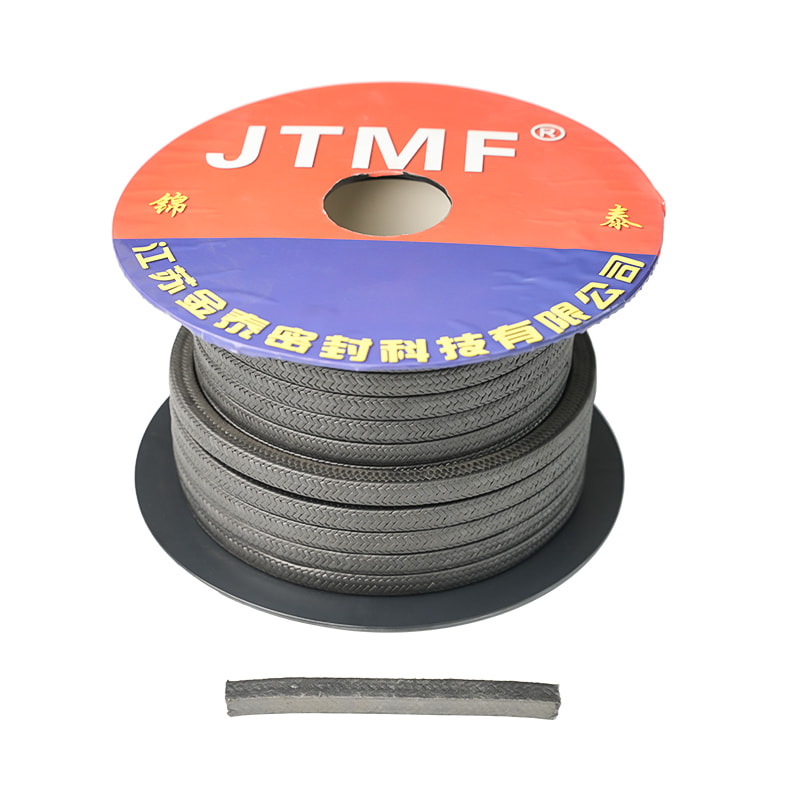

Graphite PTFE Gland Packing Material Gland Seal Packing

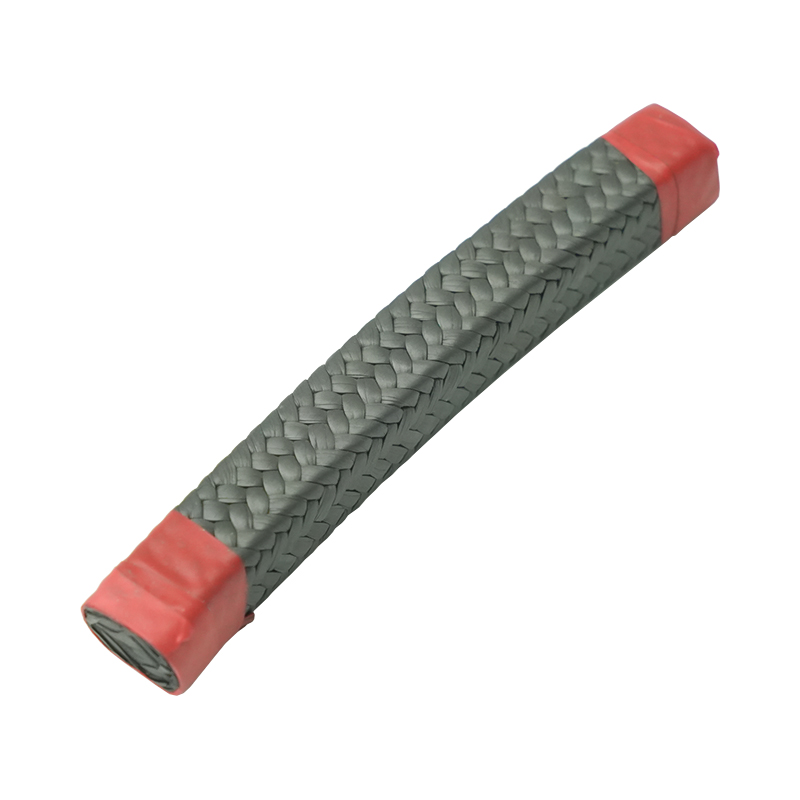

Composite aramid fiber packing is made of imported chopped Aramid fiber mixed with imported technology and impregnated with polytetrafluoroethylene and high-temperature lubricant. The packing is softer than ordinary long-fiber aramid packing. Polytetrafluoroethylene The content of vinyl fluoride emulsion and high-temperature lubricant is higher and the density is better, ensuring high lubrication and low wear of the shaft. It is especially suitable for rotating and reciprocating equipment with abrasive and sand-containing media, high pressure, and high linear speed. seal.

Graphite PTFE Gland Packing Material Gland Seal Packing - Engineered for Industrial Sealing Performance

Product Features

- Composition: Manufactured from a combination of graphite and polytetrafluoroethylene (PTFE) to provide chemical resistance and thermal stability.

- Sealing Capability: Offers consistent compression recovery and low friction for rotary and reciprocating equipment applications.

- Operational Range: Suitable for a broad temperature and pressure range, enabling use in demanding industrial processes.

Product Description

The Graphite PTFE Gland Packing is designed for effective sealing of pumps, valves, and other rotary or reciprocating machinery. Its structure integrates the lubricity of PTFE with the thermal conductivity and chemical inertness of graphite, ensuring minimal leakage and extended operational life under challenging conditions.

Manufactured in accordance with international standards, this gland seal packing undergoes precision extrusion and compression processes. It demonstrates reliable performance across various chemical media, including acids, alkalis, and solvents, and meets technical requirements for industrial sealing solutions.

Applications

This gland packing material is applicable in the following industrial scenarios:

- Sealing of chemical processing pumps and valves handling aggressive fluids.

- High-temperature steam and thermal fluid systems in industrial plants.

- Rotary and reciprocating machinery in petrochemical, power generation, and water treatment facilities.

FAQ

1. What types of fluids can Graphite PTFE Gland Packing handle?

This packing is compatible with a wide range of fluids including acids, alkalis, solvents, oils, and steam, due to its chemical inertness and thermal stability.

2. How is this gland packing installed for optimal performance?

Installation requires proper gland compression: ensure even tightening around the shaft, avoid over-compression, and stagger packing rings to prevent leakage and reduce wear.

3. What are the temperature and pressure limits for this packing material?

The material operates effectively between -200°C and 280°C, with a pressure rating up to 40 bar, making it suitable for both high-temperature and moderate-pressure industrial applications.

Specifications

|

Temperature |

-75℃-+280℃ |

||

|

Pressure |

2.5Mpa(Rotary pump) |

8Mpa(Reciprocating pump) |

15Mpe(Valve) |

|

FH Value |

0-14 |

|

|

|

Line speed |

12M/S(Rotary pump) |

2M/S(Reciprocating pump) |

2 M/S(Valve) |

|

Available cross-section sizes |

≥1/8''~≤3''(3x3-75×75mm) |

||

|

Density |

1.65-1.75g/cm³ |

||

|

Note: (1) Gore fiber packing imported from the United States can also be provided upon request. Various performance ratiosPolyethylene graphite packing is better and has a long service life (2) If necessary, iron-red silicone strip elastomer can be added to the core of the packing. |

|||

KEEP IN TOUCH

-

In the demanding environments of power generation, petrochemical processing, and maritime engineering, the integrity of a flanged joint is paramount. Engineers often face the dilemma of selecting betw...

READ MORE -

In high-utility power generation, the integrity of a steam turbine relies heavily on the performance of its static sealing interfaces. A metal gasket ring is often the first line of defense against ca...

READ MORE -

In the demanding landscape of industrial fluid handling, maintaining seal integrity in high-temperature environments is a paramount challenge for engineers. As centrifugal pumps and valves operate und...

READ MORE

Environmental protection and high efficiency coexist, how does graphite PTFE packing lead the new trend of sealing technology?

In the industrial wave of pursuing high efficiency and sustainable development, sealing technology, as a key link to ensure stable operation of equipment and environmental protection, is undergoing unprecedented changes. Jiangsu Jintai Sealing Technology Co., Ltd., a well-known enterprise located in Yuanzhu Industrial Park, Taixing City, Jiangsu Province, has been leading the new direction of sealing technology since its establishment in 2004 with technology as the rudder and innovation as the sail. Among them, graphite PTFE packing is the shining pearl among its many innovative achievements.

Graphite PTFE packing, an innovative product that combines the dual advantages of graphite and polytetrafluoroethylene (PTFE), is a profound interpretation of Jiangsu Jintai's concept of high efficiency and environmental protection. Graphite, with its excellent high temperature resistance, corrosion resistance and self-lubricating properties, provides a solid performance foundation for packing; while PTFE, with its excellent chemical stability, low friction coefficient and non-stickiness, adds more flexibility and durability to the packing. The perfect combination of the two not only improves the sealing performance of the packing, but also sets a new benchmark in the field of environmental protection.

With its excellent performance, graphite PTFE packing has won the favor of many industries such as shipbuilding, electricity, steel, chemical industry, machinery, etc. In the field of shipping, it guards the heart of engines and pumps to ensure the safety and smoothness of navigation; in the power industry, it helps the stable operation of boilers and steam turbines to escort light and warmth; in the chemical industry, it has become a capable assistant in handling corrosive media, building a solid line of defense for production safety.

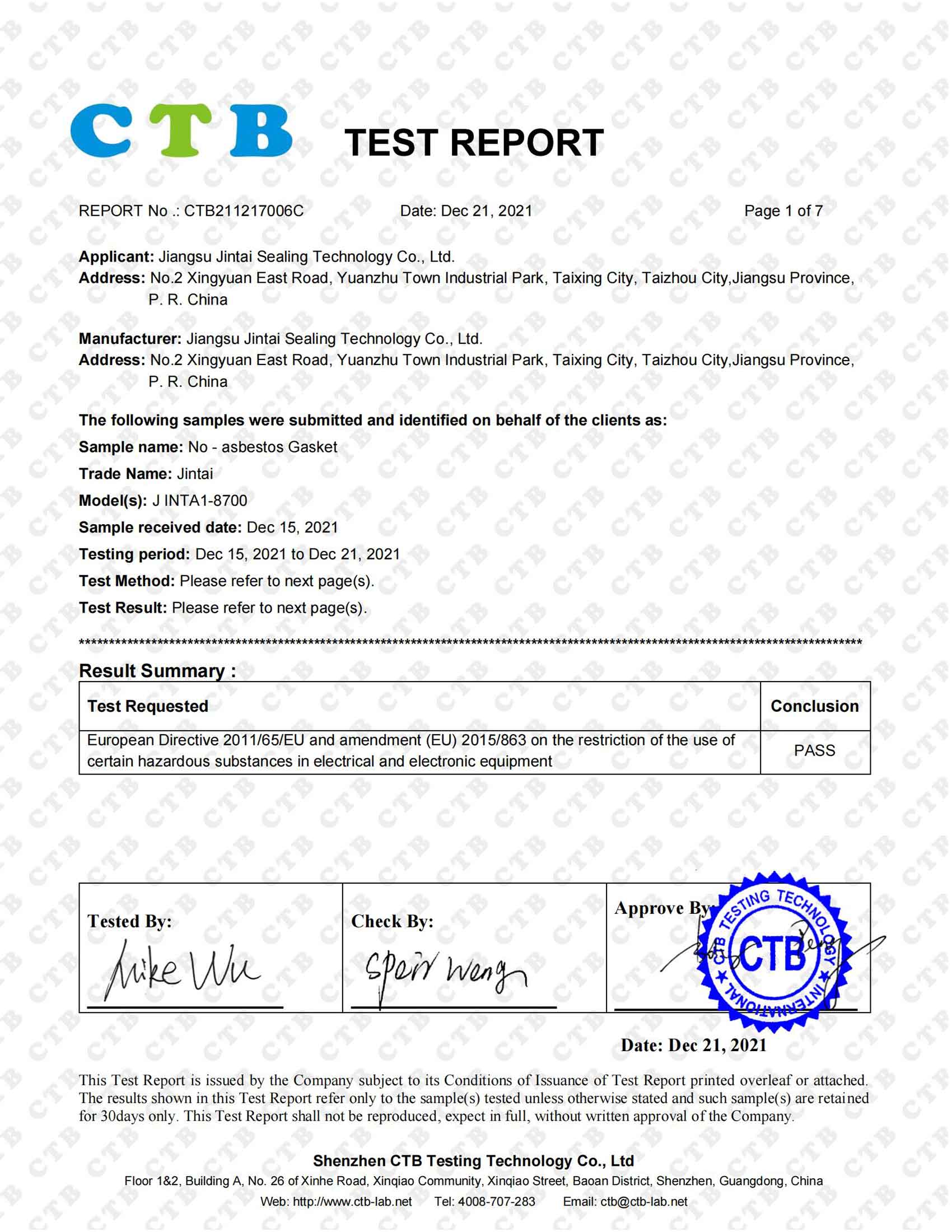

Jiangsu Jintai is well aware that scientific and technological innovation is the inexhaustible driving force for the development of enterprises, and product quality is the lifeline of enterprises. The company always puts scientific research investment and quality management first. By forming a research and development team composed of industry experts and technical backbones, we continue to overcome technical difficulties and launch new products that meet market demand. At the same time, we have established a complete quality management system and monitoring system to ensure that each product can meet the highest standards of the industry and win the trust and praise of customers.

Today, when environmental protection is becoming a global consensus, Jiangsu Jintai actively responds to the call of the country and is committed to the research and development and production of environmentally friendly sealing materials. As one of the best, graphite PTFE packing not only meets customers' demand for high-performance sealing materials, but also makes positive contributions to environmental protection. With its low friction and low energy consumption characteristics, it reduces energy consumption and carbon emissions during equipment operation; at the same time, its recyclable and reusable material characteristics also contribute to resource recycling and environmental protection.

Graphite PTFE packing is not only an outstanding achievement of Jiangsu Jintai Sealing Technology Co., Ltd. in the field of sealing technology, but also a vivid practice of the company's implementation of the concept of green development and promotion of industry progress. In the future, Jiangsu Jintai will continue to adhere to the development concept of innovation, environmental protection and high efficiency, and contribute more to promoting the advancement of my country's sealing technology and industrial upgrading.

Eng

Eng  русский

русский