What Are the Performance Advantages of carbon gland packing in High-Temperature Pump Applications?

2026.01.29

2026.01.29

Industry News

Industry News

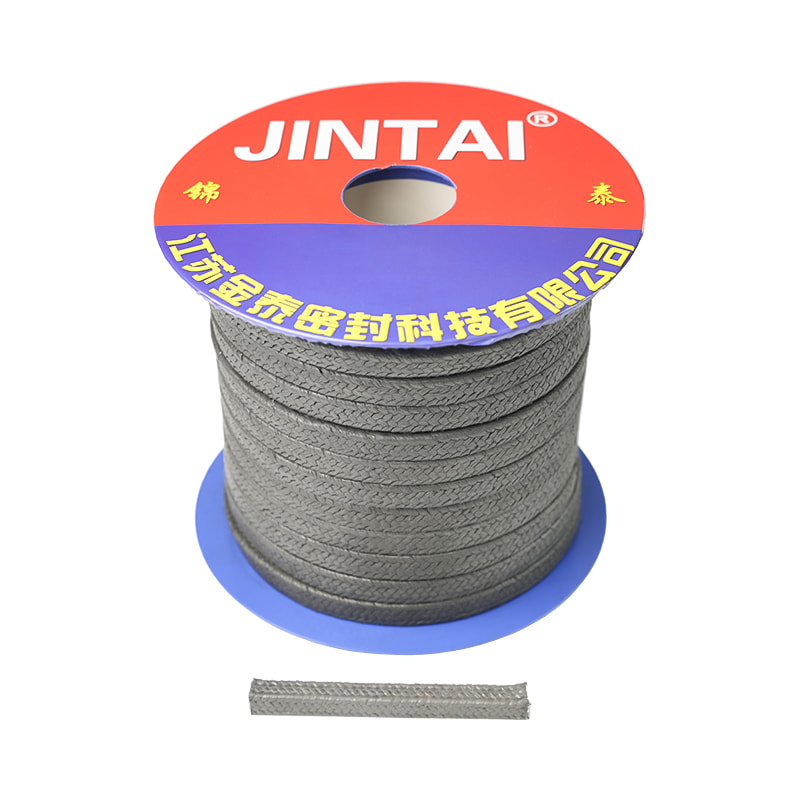

In the demanding landscape of industrial fluid handling, maintaining seal integrity in high-temperature environments is a paramount challenge for engineers. As centrifugal pumps and valves operate under extreme thermal loads, traditional sealing materials often fail due to carbonization or loss of elasticity. This is where carbon gland packing emerges as a critical solution. Jiangsu Jintai Sealing Technology Co., Ltd., founded in 2004, has spent decades perfecting the manufacture of these high-end components. Through our premium brand, Nofstein, we provide industrial sealing solutions with carbon gland packing that meet the rigorous needs of the power, chemistry, and iron and steel industries. Our products, backed by CCS classification society identification and rigorous environmental testing, represent the pinnacle of sealing technology.

Thermal Stability and Heat Dissipation Capabilities

The primary advantage of carbon gland packing lies in its exceptional thermal conductivity. Unlike synthetic fibers that may act as insulators and trap heat, carbon fibers facilitate the rapid dissipation of heat away from the shaft. This prevents localized "hot spots" that can lead to premature sleeve wear. According to the 2024 standards published by the European Sealing Association (ESA), advanced carbon-based materials are now rated for continuous operation at temperatures exceeding 600°C in non-oxidizing atmospheres, providing a safety margin that significantly exceeds standard PTFE-based packings.

Source: European Sealing Association: Sealing Technology Standards and Packing Guide 2024

Comparison: Thermal Performance of Packing Materials

Carbon fiber maintains its structural integrity at temperatures where PTFE or aramid fibers begin to degrade or melt. This makes high temperature carbon fiber packing for pumps the preferred choice for boiler feed pumps and thermal oil systems.

| Material Property | PTFE Packing | Carbon Gland Packing |

| Max Temperature (Oxidizing) | ~260°C | ~450°C - 500°C |

| Thermal Conductivity | Low (Insulating) | High (Heat Dissipating) |

| Dimensional Stability | High creep/cold flow | Excellent; minimal shrinkage |

Friction Reduction and Mechanical Efficiency

Mechanical efficiency in pumps is often dictated by the friction coefficient at the stuffing box interface. Utilizing low friction carbon yarn packing for valves and pumps reduces the power consumption required to rotate the shaft. Carbon's self-lubricating properties, often enhanced with graphite impregnation, minimize the friction-generated heat. Industry data from 2025 suggests that upgrading to braided carbon gland packing specifications can improve pump energy efficiency by 2-5% in high-pressure applications compared to standard fibrous materials.

Source: Fluid Sealing Association: Technical Guidelines for Compression Packing Efficiency 2025

Chemical Resistance and Structural Integrity

In high-temperature chemical processing, seals must withstand aggressive media across the pH spectrum. A comprehensive carbon gland packing chemical resistance chart reveals that carbon is inert to almost all chemicals, including strong acids and alkalis, with the exception of strong oxidizers. This versatility allows procurement managers to standardize their inventory across multiple departments, from shipping to steel manufacturing. Jiangsu Jintai Sealing's commitment to quality ensures our Nofstein brand products utilize advanced manufacturing processes to maintain fiber density and structural strength even in acidic environments.

Comparison: Chemical and Pressure Limits

While asbestos-free gaskets and specialized rubber products have their place, carbon gland packing handles significantly higher pressure-velocity (PV) limits, making it suitable for high-speed rotating equipment.

| Operational Limit | Standard Synthetic Packing | Premium Carbon Fiber Packing |

| pH Range | 2 - 12 | 0 - 14 (Except strong oxidizers) |

| Shaft Speed (m/s) | Up to 10 m/s | Up to 25 m/s |

| Pressure (Bar) | Variable; typically lower | Up to 250 Bar (Static) / 25 Bar (Rotary) |

Environmental Compliance and Quality Management

Modern industry requires industrial sealing solutions with carbon gland packing that are not only effective but also environmentally responsible. Our facility at Yuanzhu Industrial Park adheres to strict quality management manuals and has passed the CiT test for environmental protection. Carbon fiber is inherently asbestos-free, aligning with the global push for non-hazardous industrial components. Since the completion of our sealing technology industrial park in 2012, we have focused on technological innovation to ensure that our braided products provide the lowest possible leakage rates, assisting companies in meeting increasingly stringent emission standards.

Conclusion: The Strategic Value of High-Spec Carbon Seals

The performance advantages of carbon gland packing in high-temperature pump applications—ranging from superior heat dissipation to low friction and broad chemical compatibility—make it an indispensable asset for high-end industrial operations. By sourcing from an established enterprise like Jiangsu Jintai Sealing Technology Co., Ltd., customers gain access to decades of scientific expertise and a vigorous foreign trade group capable of supporting major global projects. Whether you are in the power sector or chemical processing, our Nofstein brand ensures high-standard sealing solutions that improve equipment uptime and operational safety.

Frequently Asked Questions (FAQ)

- Can carbon gland packing be used in potable water applications? While carbon is chemically inert, it is primarily used in industrial and chemical processes. For potable water, specific food-grade certifications (such as WRAS or FDA) must be verified depending on the impregnation material used.

- How do I determine the correct braided carbon gland packing specifications for my pump? You must consider the shaft diameter, stuffing box depth, operating temperature, pressure, and the pH of the fluid. Our technical team can provide a tailored calculation for your specific equipment.

- Does high temperature carbon fiber packing for pumps require a break-in period? Yes. Like all compression packings, it should be adjusted gradually during the first few hours of operation to allow for thermal expansion and to establish a controlled leak rate for lubrication.

- What is the typical shelf life of industrial sealing solutions with carbon gland packing? Carbon fiber itself has an almost indefinite shelf life; however, the lubricants (like graphite or oil) may have a storage limit of 2-5 years depending on environmental conditions.

- Is low friction carbon yarn packing for valves suitable for steam service? Absolutely. It is one of the most reliable materials for high-pressure steam valves due to its resistance to volume loss and thermal shock.

Eng

Eng  русский

русский