Engineering Sealing Integrity: Performance and Lifespan of PTFE Graphite Gland Packing in Extreme Conditions vs. pure graphite gland packing

2025.12.12

2025.12.12

Industry News

Industry News

- 1 I. Sealing Solutions for Extreme Industrial Environments

- 2 II. Material Science of PTFE Graphite Packing

- 3 III. Performance in High-Temperature and High-Pressure Environments

- 4 IV. Chemical Resistance and Corrosive Media

- 5 V. Service Life, Wear, and Maintenance

- 6 VI. Quality Assurance and B2B Procurement

- 7 VII. Conclusion: Specifying the Right Gland Packing

- 8 VIII. Frequently Asked Questions (FAQ)

- 8.1 1. What are the key factors limiting the maximum temperature of PTFE Graphite Packing?

- 8.2 2. When should an engineer choose reinforced graphite packing over standard pure graphite gland packing?

- 8.3 3. How is chemical compatibility assessed for PTFE Graphite Packing in a pump?

- 8.4 4. What leakage standards should B2B buyers reference for valve packing?

- 8.5 5. Is PTFE Graphite Packing suitable for high-pressure steam service?

I. Sealing Solutions for Extreme Industrial Environments

In critical industrial applications—spanning shipping, power generation, iron and steel, and chemistry—the integrity of dynamic seals is paramount. The choice of gland packing material, specifically the distinction between pure graphite gland packing (PGGP) and PTFE Graphite Packing (PTFE-GP), dictates operational reliability, maintenance cycles, and safety.

Jiangsu Jintai Sealing Technology Co., Ltd., founded in 2004, operates under the high-end sealing product brand Nofstein, focusing on providing sophisticated sealing solutions. With sound quality management manuals and certifications like the CCS classification society quality system identification, we leverage scientific expertise and advanced manufacturing processes to develop new materials that adapt to challenging market needs.

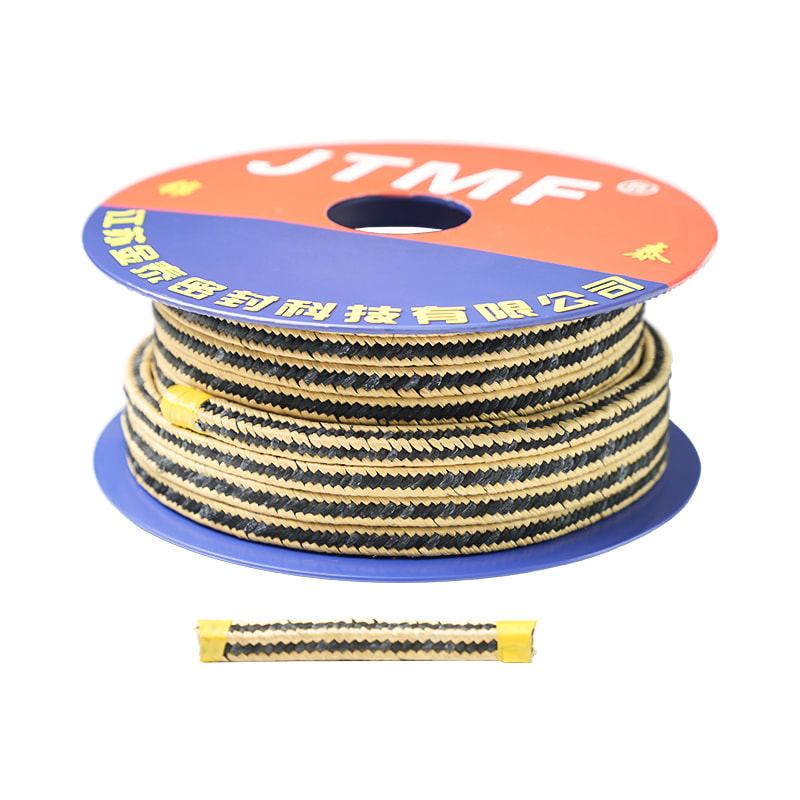

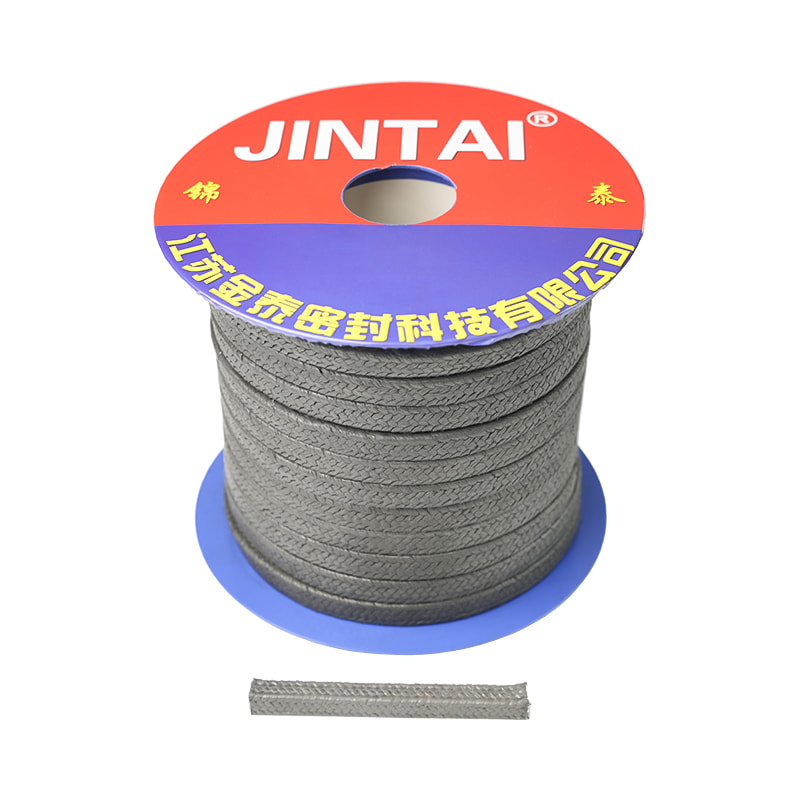

High-Temperature Nano-Graphite Gland Packing

II. Material Science of PTFE Graphite Packing

PTFE Graphite Gland Packing is a composite material engineered to combine the strengths of both constituents. Pure graphite gland packing excels in thermal stability and provides superior sealing under high temperatures due to its low coefficient of friction and high thermal conductivity. However, its chemical resistance is limited in strong oxidizing acids.

Synergistic Performance and Reinforcement

The inclusion of PTFE (Polytetrafluoroethylene) fibers or dispersion substantially improves the chemical inertness of the packing, extending its useful acidity and alkalinity range. Furthermore, B2B buyers must consider structural integrity:

For applications demanding higher mechanical strength and extrusion resistance, advantages of reinforced graphite gland packing vs standard are significant. Reinforcement, often using high-modulus fibers such as carbon or aramid within the braid structure, prevents particle migration and enhances dimensional stability under high gland follower pressure, improving overall service life.

III. Performance in High-Temperature and High-Pressure Environments

The primary concern for procurement engineers is the packing's ability to maintain a seal envelope under extreme thermal and mechanical cycling, especially in steam service. We must analyze the PTFE graphite packing high temperature sealing limits.

Thermal and Pressure Stability Comparison

While PGGP offers continuous temperature ratings up to four hundred fifty degrees Celsius to five hundred fifty degrees Celsius (depending on the presence of inhibitors), the PTFE component limits the continuous working temperature of PTFE-GP. PTFE begins to soften and degrade above approximately two hundred sixty degrees Celsius. Therefore, the selection must be dictated by the process temperature, particularly when following a strict B2B guide to selecting graphite packing for steam valves.

The comparison below highlights the operating limitations:

Thermal and Pressure Limits of Graphite Gland Packing Materials

| Packing Material Type | Max Continuous Temperature (Celsius) | Max Operating Pressure (Bar, Valves) | Primary Limitation |

|---|---|---|---|

| Pure Graphite Gland Packing (PGGP) | 450 - 550 (Inhibited) | 300 | Chemical Attack (Oxidizing Media) |

| PTFE Graphite Packing (PTFE-GP) | 260 | 150 | Thermal Softening/Degradation of PTFE |

| Reinforced Graphite Packing | 450 - 550 | 400 or higher | Chemical Attack (Similar to PGGP) |

Sealing Integrity and Leakage Standards

Maintaining ultra-low fugitive emissions is a technical necessity. Professional manufacturers adhere to stringent tests, aligning with pure graphite packing leakage rate testing standards such as API 622 or ISO 15848-1. In high-pressure applications, the higher mechanical stability of a reinforced packing system is often required to achieve and maintain these ultra-low rates over thousands of thermal cycles.

IV. Chemical Resistance and Corrosive Media

The inclusion of PTFE is primarily to address the chemical vulnerability of graphite. Pure graphite gland packing can degrade rapidly in strong oxidizing agents (e.g., concentrated nitric acid, oleum, fluorine) above room temperature, leading to catastrophic seal failure.

Chemical Compatibility: The PTFE Advantage

PTFE is virtually inert to all industrial chemicals, offering a substantial advantage. For B2B applications, assessing the chemical compatibility of graphite PTFE packing in pumps is essential. PTFE-GP is the preferred choice for processes handling moderate temperatures and a wide range of corrosive acids or strong alkalis where PGGP is unsuitable.

However, engineers must be cautious about the 'Black Box' scenario: The presence of carbon or graphite in PTFE packing can still introduce a risk of galvanic corrosion when installed in contact with certain stainless steel or exotic alloys, especially in the presence of an electrolyte. A full material compatibility matrix must be consulted before installation.

V. Service Life, Wear, and Maintenance

Long service life reduces Total Cost of Ownership (TCO). The natural lubricity of graphite significantly reduces shaft friction and wear, leading to lower maintenance costs. The technical goal, reinforced by pure graphite packing leakage rate testing standards, is to prevent leakage while minimizing shaft damage.

PTFE-GP generally offers better resistance to aggressive chemical wash-out and hardened shaft wear than un-reinforced PGGP. However, for maximum wear resistance, specific reinforcing agents within the packing compound are often necessary, which Nofstein provides through our advanced sealing products line.

VI. Quality Assurance and B2B Procurement

As a large comprehensive sealing technology enterprise, Nofstein specializes in researching, manufacturing, and selling various types of seals and asbestos-free gaskets. Our ability to collaborate with many industries such as shipping and chemistry, and our rich experience and firm confidence, enable us to undertake various major projects globally, exporting goods to countries in Eastern Europe, Southeast Asia, and Africa. We ensure that our products, whether pure graphite gland packing or complex composite designs, consistently meet or exceed international standards like the CCS classification society identification.

VII. Conclusion: Specifying the Right Gland Packing

For B2B procurement, the decision between pure graphite gland packing and its PTFE-enhanced counterpart is a trade-off between maximum temperature resistance (PGGP) and comprehensive chemical inertness (PTFE-GP). By consulting the B2B guide to selecting graphite packing for steam valves and analyzing the process media against the PTFE graphite packing high temperature sealing limits, engineers can select the precise Nofstein product that guarantees sealing integrity and a long service life.

VIII. Frequently Asked Questions (FAQ)

1. What are the key factors limiting the maximum temperature of PTFE Graphite Packing?

The maximum continuous operating temperature of PTFE Graphite Packing is limited by the thermal softening point of the PTFE component, which is typically around two hundred sixty degrees Celsius. Above this point, the PTFE loses its dimensional stability, leading to creep and seal failure. This defines the PTFE graphite packing high temperature sealing limits.

2. When should an engineer choose reinforced graphite packing over standard pure graphite gland packing?

Reinforced graphite packing should be chosen for high-pressure (200 Bar or higher) or dynamic service applications where extrusion resistance and mechanical stability are critical. The advantages of reinforced graphite gland packing vs standard include superior resistance to pressure cycling and improved durability against shaft movement.

3. How is chemical compatibility assessed for PTFE Graphite Packing in a pump?

Chemical compatibility, especially for chemical compatibility of graphite PTFE packing in pumps, is assessed by verifying the acidity/alkalinity range and oxidizing potential of the process fluid. While PTFE is chemically inert across nearly the entire acidity/alkalinity range, the graphite component restricts usage in strong oxidizing acids.

4. What leakage standards should B2B buyers reference for valve packing?

B2B buyers should reference standards like API 622 or ISO 15848-1. These standards define the rigorous thermal and mechanical cycling tests required to certify ultra-low fugitive emissions, providing the technical metrics for pure graphite packing leakage rate testing standards.

5. Is PTFE Graphite Packing suitable for high-pressure steam service?

PTFE Graphite Packing is only suitable for steam service where the temperature remains below the two hundred sixty degrees Celsius limit of the PTFE component. For high-pressure, superheated steam, a non-PTFE pure graphite gland packing or a reinforced graphite solution is required, as detailed in any B2B guide to selecting graphite packing for steam valves.

Eng

Eng  русский

русский