Evaluating Graphite Content and Braiding Structure in Pure Graphite Gland Packing

2025.12.18

2025.12.18

Industry News

Industry News

- 1 I. Introduction: The Technical Parameters of Sealing

- 2 II. Material Composition: The Influence of Graphite Content

- 3 III. Structural Engineering: Braiding and Density

- 4 IV. Technical Assessment and Procurement Criteria

- 5 V. Conclusion: Precision Engineering for Sealing Solutions

- 6 VI. Frequently Asked Questions (FAQ)

- 6.1 1. How does the thermal conductivity of graphite benefit the packing's lifespan?

- 6.2 2. What is the standard testing procedure for the coefficient of friction?

- 6.3 3. Does higher density always mean lower leakage for PTFE graphite packing?

- 6.4 4. Which braiding structure offers the best wear resistance for dynamic applications?

- 6.5 5. What material characteristic defines a packing as meeting Low friction expanded PTFE graphite packing specifications?

I. Introduction: The Technical Parameters of Sealing

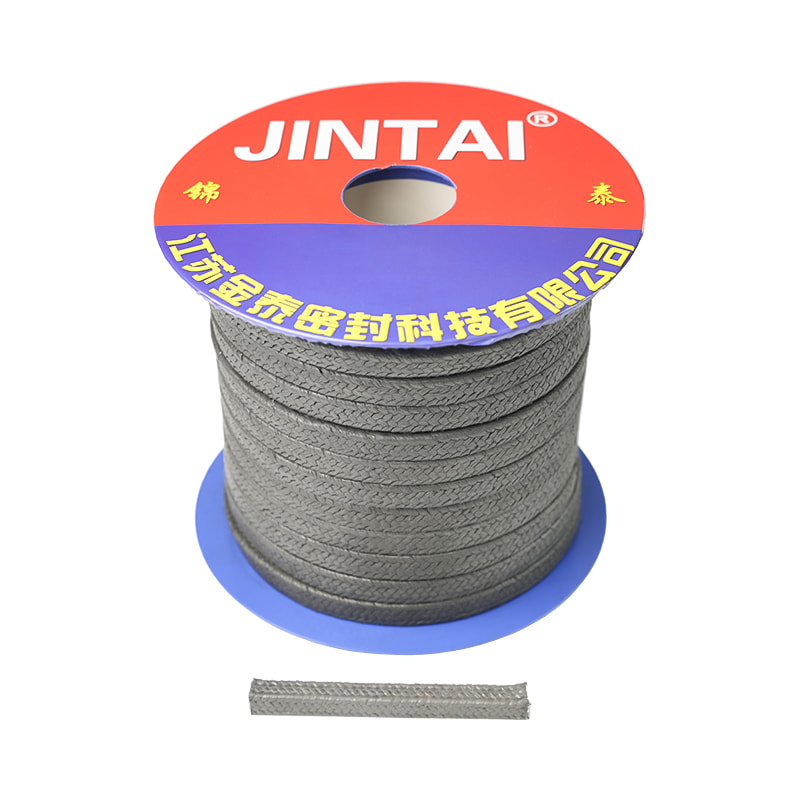

In the highly demanding environments of modern industrial machinery—across the power generation, chemical processing, and shipping sectors—the function of gland packing is paramount. The seal must be robust enough to prevent fluid leakage while generating minimal friction and surviving repeated wear cycles. For this critical balance, pure graphite gland packing, often incorporating PTFE, remains the material standard. Evaluating this product requires a deep dive into two primary technical variables: the graphite content ratio and the packing's structural braiding pattern.

Jiangsu Jintai Sealing Technology Co., Ltd., founded in 2004, is a large comprehensive sealing technology enterprise that, through its high-end Nofstein brand, focuses on providing superior sealing solutions. Our accumulation of scientific experiments and rigorous quality management manuals, backed by certifications such as the CCS classification society identification, enables us to research, manufacture, and sell specialized seals that integrate seamlessly with major industries, facilitating long-term success with our partners.

II. Material Composition: The Influence of Graphite Content

The graphite percentage within PTFE graphite packing is directly engineered to modulate the packing's frictional and thermal properties.

A. Graphite Content and Friction Reduction

Graphite acts as a highly effective solid lubricant. When incorporated into PTFE fibers, it creates a self-lubricating surface that transfers a low-friction film onto the rotating shaft. Higher graphite purity and content directly correlate with a lower running coefficient of friction, which is vital for minimizing energy consumption and shaft wear. Meeting Low friction expanded PTFE graphite packing specifications requires a high graphite ratio, typically exceeding 25% by weight, to achieve this lubrication effect effectively at the packing surface.

The technical advantage of high graphite content is the reduction of running temperature, as confirmed by laboratory testing.

| Graphite Content Ratio (Nominal) | Typical Coefficient of Friction (COF) | Wear Life Rating (Relative) |

|---|---|---|

| Low (15% - 20%) | 0.20 - 0.35 | Fair (Higher heat generation) |

| High (25% - 35%) | 0.08 - 0.15 (Meets Low friction expanded PTFE graphite packing specifications) | Excellent (Low heat, high durability) |

B. Thermal Transfer and High Graphite Content

Graphite possesses exceptional thermal conductivity. A rigorous High graphite content PTFE packing thermal conductivity analysis confirms that increasing the graphite percentage enhances the packing's ability to conduct heat away from the friction interface (the shaft surface) and into the packing gland where it can be dissipated. This heat management capability is critical in preventing localized overheating, which is the primary cause of premature wear and thermal expansion failure in packing materials.

III. Structural Engineering: Braiding and Density

Beyond material composition, the mechanical construction of the packing rope significantly influences its sealing performance and dimensional stability.

A. Braiding Structure and Wear Resistance

The braiding pattern dictates how the individual strands of PTFE and graphite yarn lock together. For example, a lattice braid provides greater material density and stability than a square braid, offering superior resistance to extrusion under high gland pressure. Understanding the Braiding structure effect on graphite packing wear resistance is key for procurement. A tightly woven, interlocking braid minimizes yarn migration, ensuring that the packing retains its structural integrity and bulk density over thousands of operational cycles, maintaining continuous contact with the shaft without fracturing.

B. Density and Sealing Effectiveness

The bulk density of the finished packing rope is directly related to its sealing effectiveness. A thorough PTFE graphite gland packing density vs leakage rate study shows that higher density reduces the void space within the packing, minimizing potential leak paths. Optimal density must be achieved through precise tension control during braiding, ensuring maximum compression resistance without compromising the material's flexibility. We validate performance through technical procedures like the Friction coefficient testing for pure graphite packing to ensure both low friction and high sealing capability are achieved simultaneously.

| Braiding Structure | Material Stability (Under Pressure) | Resistance to Extrusion/Migration |

|---|---|---|

| Square Braid | Fair (Prone to some material shift) | Moderate (Lower density retention) |

| Lattice/Diagonal Braid | Excellent (Interlocking design) | High (Optimizes Braiding structure effect on graphite packing wear resistance) |

IV. Technical Assessment and Procurement Criteria

Procurement professionals should rely on certified data and proven manufacturing expertise when selecting pure graphite gland packing.

A. Quality Control and Certification

Our company's participation in international certification processes, such as the CiT test for environmental protection and the CCS classification society quality system identification, ensures that the base materials (PTFE and graphite) meet the highest purity and safety standards. This verification is essential for guaranteeing the performance claims related to Low friction expanded PTFE graphite packing specifications and chemical compatibility.

B. Performance Customization

As a large comprehensive sealing technology enterprise, Jintai Sealing provides customized solutions. We leverage technological innovation to modify braiding tension and graphite content—informed by High graphite content PTFE packing thermal conductivity analysis—to develop specialized products that form a complete sealing set for demanding industries like shipping and power, fulfilling diverse project requirements globally.

V. Conclusion: Precision Engineering for Sealing Solutions

The high performance of pure graphite gland packing is a direct result of precision engineering in material composition and structure. Optimizing graphite content is vital for reducing friction and managing heat, while selecting the correct braiding structure determines wear resistance and sealing integrity. Through rigorous testing, from Friction coefficient testing for pure graphite packing to analyzing PTFE graphite gland packing density vs leakage rate, Jiangsu Jintai Sealing Technology ensures the delivery of safe, reliable, and economically durable sealing solutions to our partners worldwide.

VI. Frequently Asked Questions (FAQ)

1. How does the thermal conductivity of graphite benefit the packing's lifespan?

- A: The high thermal conductivity allows the packing to efficiently dissipate frictional heat generated at the shaft interface. This prevents localized heat build-up, which can lead to premature material degradation and shaft scoring, thus prolonging the service life, as confirmed by High graphite content PTFE packing thermal conductivity analysis.

2. What is the standard testing procedure for the coefficient of friction?

- A: Friction coefficient testing for pure graphite packing is typically performed using a controlled ring test method. The packing is installed under specific compression in a gland, and the force required to rotate the shaft at a fixed speed is measured, allowing for an accurate calculation of the dynamic coefficient of friction.

3. Does higher density always mean lower leakage for PTFE graphite packing?

- A: Yes, generally. A high PTFE graphite gland packing density vs leakage rate study shows a correlation where higher bulk density minimizes void space, reducing potential leak paths. However, the density must not be so high as to eliminate the internal lubrication space or make the material too rigid, compromising shaft compliance.

4. Which braiding structure offers the best wear resistance for dynamic applications?

- A: Interlocking braid patterns, such as lattice or diagonal braids, offer the best wear resistance for dynamic applications. The Braiding structure effect on graphite packing wear resistance shows that this construction resists material migration and extrusion, maintaining the required dimensional stability under continuous shaft movement and gland pressure.

5. What material characteristic defines a packing as meeting Low friction expanded PTFE graphite packing specifications?

- A: Meeting Low friction expanded PTFE graphite packing specifications is defined by having a high percentage (typically over 25%) of high-purity expanded graphite within the PTFE matrix. This ensures the maximum amount of solid lubricant is available to coat the shaft surface, dramatically reducing the running coefficient of friction compared to standard packing.

Eng

Eng  русский

русский