Spiral Metal-Toothed Corrugated Metal Gaskets: A Comprehensive Guide

2025.07.19

2025.07.19

Industry News

Industry News

- 1 Understanding Spiral Wound Gaskets with Metal Teeth for High-Pressure Applications

- 2 Key Considerations When Selecting Corrugated Metal Gaskets with Spiral Reinforcement

- 3

- 4 Comparing Metal-Toothed vs Non-Toothed Spiral Gaskets in Critical Service

- 5 Maintenance and Inspection of High-Pressure Spiral Metal Gaskets

- 6 Innovations in Spiral Corrugated Seal Technology for Modern Industry

Understanding Spiral Wound Gaskets with Metal Teeth for High-Pressure Applications

Spiral wound gaskets with metal teeth represent an advanced sealing solution designed for extreme operating conditions. These specialized gaskets combine the flexibility of spiral wound construction with the bite of metal teeth to create superior sealing performance in challenging environments.

Construction and Design Features

The unique architecture of these gaskets features multiple layers of precision-engineered components:

- Spiral-wound metal strip (typically stainless steel)

- Non-metallic filler material (often graphite or PTFE)

- Corrugated metal outer ring

- Precision-cut metal teeth along the sealing surface

Performance Advantages

When compared to standard spiral wound gaskets, the metal-toothed version offers distinct benefits:

| Feature | Standard Spiral Wound | Metal-Toothed Version |

|---|---|---|

| Sealing Pressure | Up to 3000 psi | Up to 5000 psi |

| Temperature Range | -200°C to +500°C | -250°C to +800°C |

| Vibration Resistance | Moderate | Excellent |

Key Considerations When Selecting Corrugated Metal Gaskets with Spiral Reinforcement

Choosing the right corrugated metal gasket with spiral reinforcement requires careful evaluation of several technical parameters to ensure optimal performance and longevity.

Material Compatibility Factors

The selection of appropriate materials for both the metal components and filler directly impacts gasket performance:

- Media being sealed (chemical compatibility)

- Operating temperature range

- Pressure fluctuations

- Potential for thermal cycling

Installation Requirements

Proper installation techniques are crucial for corrugated metal gaskets with spiral reinforcement to achieve their designed performance:

- Surface finish requirements (typically 125-250 Ra)

- Bolt load calculations

- Compression limits

- Alignment procedures

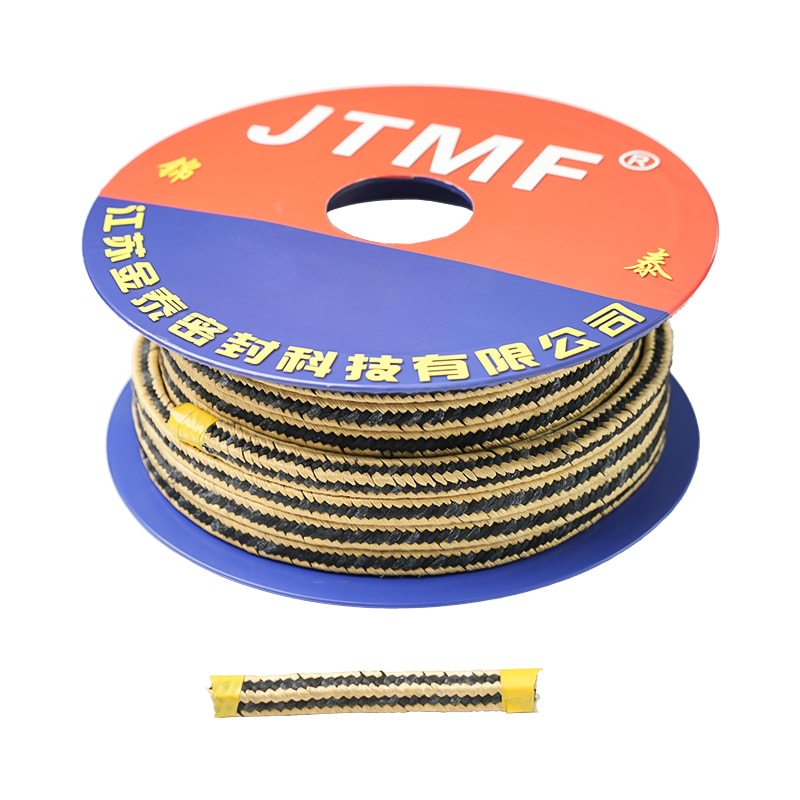

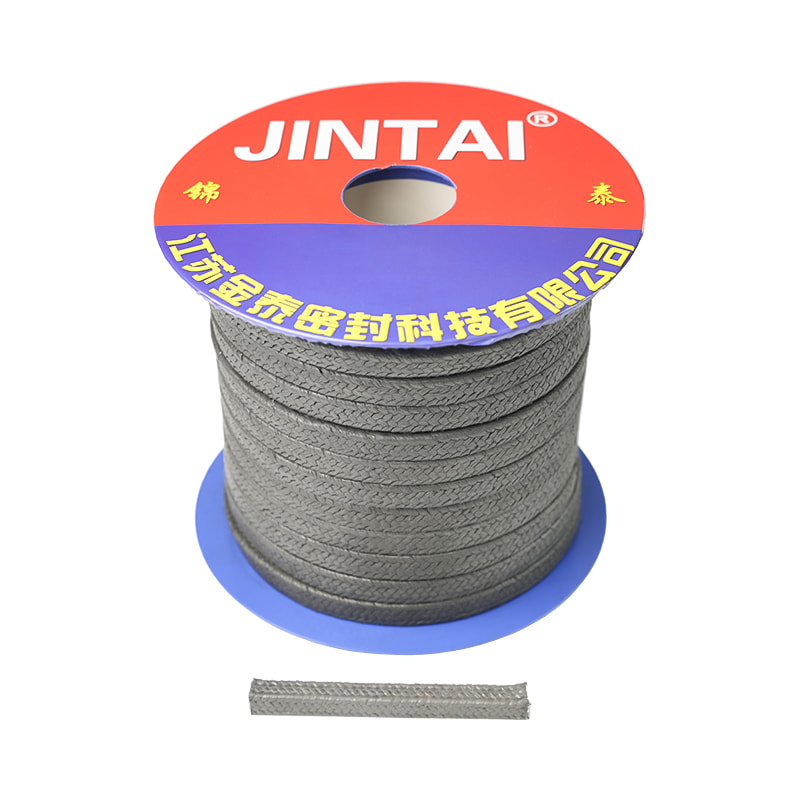

Stainless Steel Seal Ring Corrugated Metal Gasket Toothed Gasket

Comparing Metal-Toothed vs Non-Toothed Spiral Gaskets in Critical Service

The decision between toothed and non-toothed spiral gaskets depends on specific application requirements and operating conditions.

When to Choose Metal-Toothed Variants

Metal-toothed spiral gaskets excel in these challenging scenarios:

- High vibration environments

- Systems with frequent pressure cycling

- Applications requiring superior creep resistance

- Services with extreme temperature fluctuations

Limitations of Standard Spiral Wound Gaskets

While standard spiral wound gaskets perform well in many applications, they may show limitations in:

- Extreme pressure differentials

- Highly corrosive environments

- Systems with poor flange alignment

- Applications requiring zero leakage

Maintenance and Inspection of High-Pressure Spiral Metal Gaskets

Proper maintenance practices significantly extend the service life of high-pressure spiral metal gaskets and prevent unexpected failures.

Routine Inspection Procedures

Implement these inspection protocols for optimal performance:

- Visual examination for signs of compression set

- Measurement of thickness retention

- Check for metal tooth deformation

- Assessment of filler material condition

Common Failure Modes

Understanding potential failure mechanisms helps in preventive maintenance:

| Failure Mode | Primary Causes | Preventive Measures |

|---|---|---|

| Tooth deformation | Over-torquing, misalignment | Proper bolt load, alignment checks |

| Filler extrusion | Excessive pressure, temperature | Material selection, pressure limits |

Innovations in Spiral Corrugated Seal Technology for Modern Industry

Recent advancements in spiral corrugated seal technology have expanded application possibilities and improved reliability.

Material Science Developments

New material combinations enhance performance characteristics:

- High-temperature superalloys for metal components

- Advanced composite filler materials

- Corrosion-resistant coatings

- Hybrid metal-polymer constructions

Design Optimization Trends

Modern engineering approaches have led to:

- Precision laser-cut tooth patterns

- Variable pitch spiral winding

- Asymmetric corrugation profiles

- Integrated sealing surfaces

Eng

Eng  русский

русский