The Future of Industrial Sealing: How Graphite Gland Packing Enhances Efficiency

2025.07.10

2025.07.10

Industry News

Industry News

- 1 Why Graphite Gland Packing is Revolutionizing Industrial Sealing Solutions

- 2 Optimizing Performance with High-Temperature Graphite Packing

- 3 Cost-Effective Maintenance Using Graphite Packing for Pumps

- 4 Environmental Compliance with Eco-Friendly Gland Packing Materials

- 5 Extending Equipment Life with Corrosion-Resistant Valve Packing

- 6 Implementation Challenges and Solutions

Why Graphite Gland Packing is Revolutionizing Industrial Sealing Solutions

Industrial sealing technologies have evolved significantly, with graphite gland packing emerging as a game-changer. Unlike traditional materials, graphite offers superior thermal conductivity, chemical resistance, and longevity. This section explores why industries are shifting toward this advanced solution.

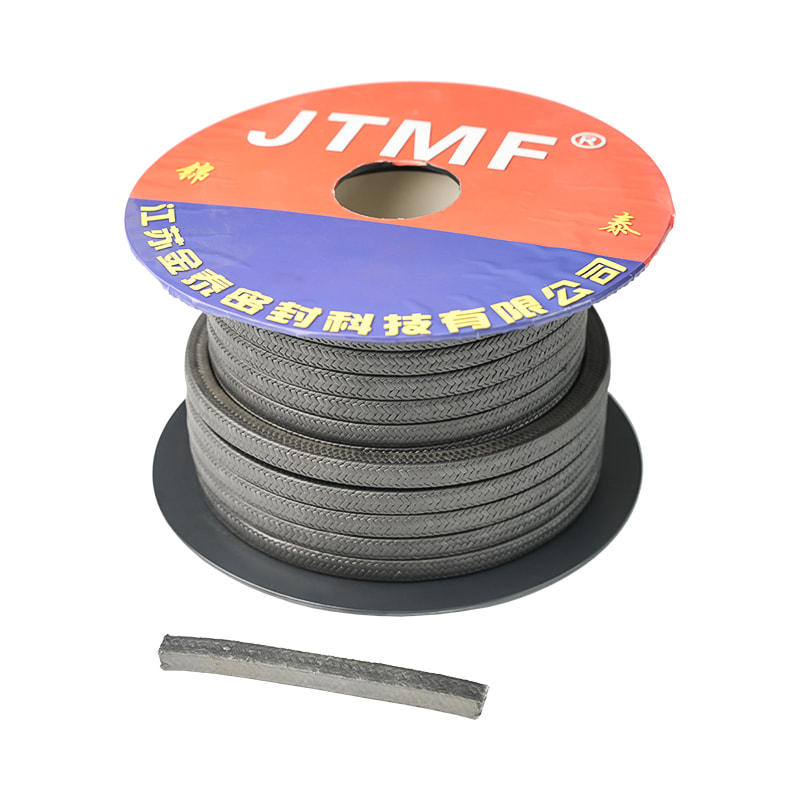

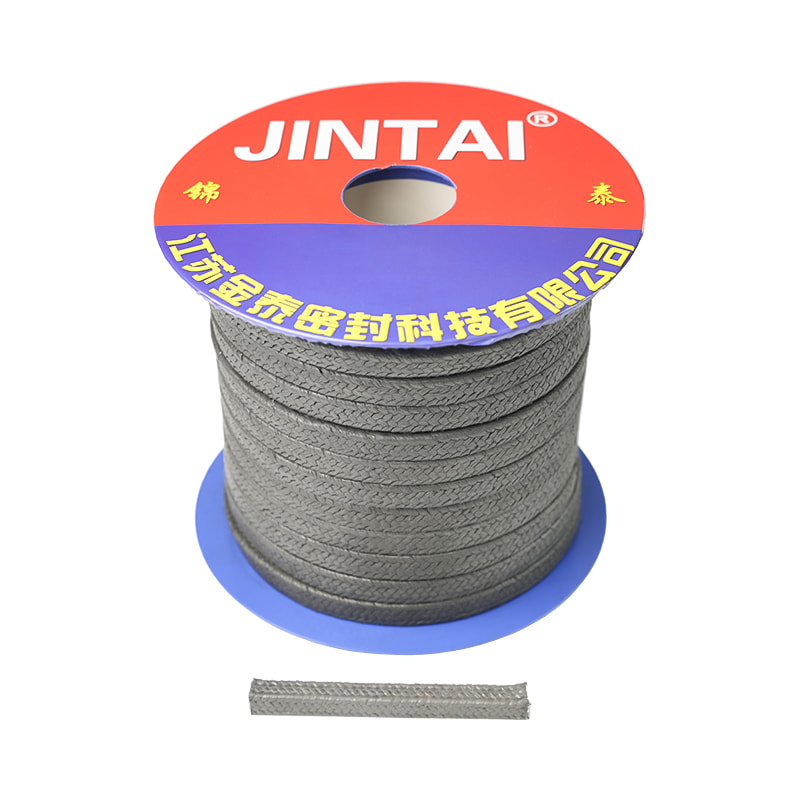

Graphite PTFE Gland Packing Material Gland Seal Packing

1.1 Key Advantages Over Traditional Materials

Compared to asbestos or PTFE-based packings, graphite gland packing withstands extreme temperatures (up to 600°C) without degradation. Its self-lubricating properties reduce shaft wear, while its flexibility ensures tighter seals under variable pressures. Below is a performance comparison:

| Parameter | Graphite | Asbestos | PTFE |

|---|---|---|---|

| Max Temperature | 600°C | 300°C | 260°C |

| Chemical Resistance | Excellent | Moderate | Good |

| Service Life | 2-3x longer | 1 year | 18 months |

Optimizing Performance with High-Temperature Graphite Packing

Industries like steel manufacturing and power generation require high-temperature graphite packing to prevent leaks in aggressive environments. This section details implementation strategies.

2.1 Installation Best Practices

Proper installation ensures maximum efficiency. Key steps include:

- Cleaning the shaft surface thoroughly

- Using staggered joint alignment for layered packing

- Applying controlled compression (20-30% of packing thickness)

Cost-Effective Maintenance Using Graphite Packing for Pumps

Rotary and centrifugal pumps benefit significantly from graphite packing for pumps, reducing downtime and maintenance costs.

3.1 Leakage Prevention Techniques

Graphite's microcrystalline structure adapts to shaft movements, minimizing leakage. A case study showed a 40% reduction in seal failures after switching to graphite in chemical processing pumps.

Environmental Compliance with Eco-Friendly Gland Packing Materials

As sustainability regulations tighten, eco-friendly gland packing materials like graphite meet both performance and environmental standards.

4.1 Comparing Environmental Impact

Unlike synthetic alternatives, graphite is naturally occurring and non-toxic. Its extended service life also reduces waste generation. Regulatory bodies increasingly recommend it for:

- Wastewater treatment plants

- Food processing equipment

- Pharmaceutical applications

Extending Equipment Life with Corrosion-Resistant Valve Packing

Valves handling corrosive fluids require corrosion-resistant valve packing. Graphite's inertness makes it ideal for:

5.1 Chemical Compatibility Analysis

Graphite demonstrates exceptional resistance to:

| Chemical | Resistance Level |

|---|---|

| Sulfuric Acid | Excellent |

| Chlorine Gas | Good |

| Caustic Soda | Excellent |

This contrasts sharply with organic fibers that degrade rapidly in acidic environments.

Implementation Challenges and Solutions

While superior, graphite packing requires specific handling. This section addresses common issues.

6.1 Overcoming Compression Set Concerns

Proper torque application during installation prevents excessive compression that could reduce packing flexibility. Manufacturers now provide torque specifications based on:

- Shaft diameter

- Operating pressure

- Temperature range

Eng

Eng  русский

русский