Ramie Gland Packing: The Ultimate Guide to Properties, Applications, and Selection

2025.07.24

2025.07.24

Industry News

Industry News

- 1 Understanding Ramie Gland Packing and Its Unique Characteristics

- 2 Key Advantages of Using Ramie Gland Packing

- 3 Proper Installation Techniques for Ramie Gland Packing

- 4 Maintenance and Troubleshooting of Ramie Gland Packing

- 5 Selecting the Right Ramie Gland Packing for Your Application

- 6 Future Trends in Ramie Gland Packing Technology

Understanding Ramie Gland Packing and Its Unique Characteristics

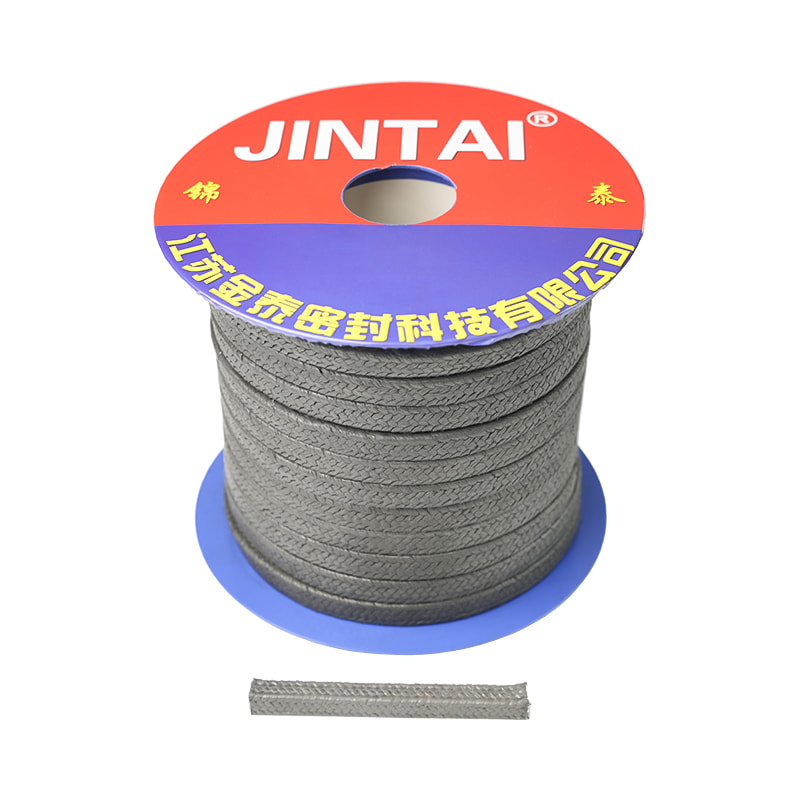

Ramie gland packing is a specialized sealing material made from natural ramie fibers, known for its exceptional durability and resistance to various environmental factors. This type of packing has gained significant popularity in industrial applications due to its unique combination of properties that make it suitable for demanding sealing requirements.

Mechanical/Water Pump PTFE Seal Packing Ramie Fiber Gland Packing

What Makes Ramie Fibers Special for Gland Packing?

Ramie fibers, derived from the Boehmeria nivea plant, possess several distinctive characteristics that make them ideal for gland packing applications:

- Exceptional tensile strength, surpassing even cotton and flax

- Natural resistance to bacteria, mildew, and rotting

- High absorbency while maintaining dimensional stability

- Excellent heat dissipation properties

- Low elongation under stress

The ramie gland packing temperature range typically spans from -40°C to 120°C (-40°F to 250°F), making it suitable for various industrial environments. Compared to synthetic alternatives, ramie packing offers better heat dissipation, which is crucial for preventing seal failure in high-friction applications.

Historical Use and Modern Applications

Ramie has been used for textile purposes for centuries, but its application in industrial sealing solutions gained momentum in the mid-20th century. Today, it serves as a reliable sealing material in:

- Pump shafts in water treatment plants

- Valve stems in chemical processing

- Rotating equipment in food processing

- Marine applications where saltwater resistance is required

Key Advantages of Using Ramie Gland Packing

The benefits of ramie gland packing extend beyond its basic sealing function, offering operational and maintenance advantages that contribute to overall system efficiency.

Environmental and Operational Benefits

Ramie packing for eco-friendly sealing solutions has become increasingly popular due to growing environmental concerns. Unlike synthetic alternatives, ramie is biodegradable and requires less energy to produce. Additional advantages include:

- Reduced friction compared to many synthetic materials

- Natural lubricity that minimizes shaft wear

- Excellent compatibility with water and mild chemicals

- Ability to absorb lubricants for improved performance

Performance Comparison with Other Packing Materials

When evaluating ramie gland packing against other common materials, several key differences emerge:

| Property | Ramie | PTFE | Graphite | Aramid |

|---|---|---|---|---|

| Temperature Range | -40°C to 120°C | -200°C to 260°C | -200°C to 650°C | -70°C to 300°C |

| Chemical Resistance | Good (mild chemicals) | Excellent | Excellent | Good |

| Environmental Impact | Biodegradable | Non-biodegradable | Non-biodegradable | Non-biodegradable |

| Cost | Moderate | High | Very High | High |

Proper Installation Techniques for Ramie Gland Packing

Correct installation is crucial for maximizing the performance and lifespan of ramie gland packing installation guide materials. Improper installation can lead to premature failure, increased maintenance costs, and potential equipment damage.

Step-by-Step Installation Process

The installation process for ramie gland packing follows these critical steps:

- Clean the stuffing box thoroughly to remove old packing and debris

- Measure the shaft or stem diameter and the stuffing box bore

- Cut packing rings at a 45-degree angle for proper butt joints

- Install rings one at a time, staggering joints by 90 degrees

- Use proper compression tools for even packing compression

- Adjust gland follower gradually to achieve proper leakage rate

Common Installation Mistakes to Avoid

Several common errors can compromise the effectiveness of ramie gland packing:

- Over-tightening the gland follower, which can cause excessive friction

- Using improper cutting techniques that create gaps in the seal

- Mixing different types of packing materials in the same stuffing box

- Failing to allow for proper run-in period with gradual tightening

- Ignoring manufacturer's recommendations for installation torque

Maintenance and Troubleshooting of Ramie Gland Packing

Proper maintenance extends the service life of ramie gland packing and ensures optimal performance throughout its operational cycle.

Routine Maintenance Procedures

The ramie packing maintenance schedule should include these key activities:

- Regular inspection of leakage rates (typically 40-60 drops per minute)

- Monitoring of packing temperature during operation

- Periodic adjustment of gland follower compression

- Lubrication as recommended by the manufacturer

- Visual inspection for signs of wear or extrusion

Troubleshooting Common Issues

When problems arise with ramie gland packing, these diagnostic steps can help identify and resolve issues:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Excessive leakage | Insufficient compression | Gradually tighten gland follower |

| Overheating | Excessive compression | Loosen gland follower slightly |

| Rapid wear | Shaft misalignment | Check and correct alignment |

| Packing extrusion | Excessive clearance | Replace with properly sized packing |

Selecting the Right Ramie Gland Packing for Your Application

Choosing the appropriate best ramie gland packing for pumps requires careful consideration of multiple factors to ensure optimal performance and longevity.

Key Selection Criteria

When selecting ramie gland packing, evaluate these critical parameters:

- Operating temperature range and fluctuations

- Media being sealed (water, chemicals, steam, etc.)

- Shaft speed and surface finish

- Pressure requirements

- Environmental regulations and compatibility

Application-Specific Recommendations

Different applications demand specific ramie gland packing characteristics:

Water Treatment Applications

For ramie gland packing for water pumps, consider these specifications:

- Typically 1/4" to 1/2" square cross-section

- May include corrosion-resistant wire reinforcement

- Often impregnated with food-grade lubricants

- Should meet potable water standards when applicable

Chemical Processing Applications

Chemical environments require special considerations:

- Verify chemical compatibility with process media

- Consider PTFE-impregnated ramie for aggressive chemicals

- May require more frequent maintenance inspections

- Monitor for signs of chemical degradation

Future Trends in Ramie Gland Packing Technology

The evolution of ramie gland packing continues as manufacturers develop new formulations and treatments to enhance performance.

Innovations in Material Treatment

Recent advancements in ramie gland packing technology include:

- Improved impregnation techniques for better lubrication

- Hybrid compositions combining ramie with synthetic fibers

- Nanotechnology treatments for enhanced wear resistance

- Eco-friendly lubricant formulations

Sustainability and Circular Economy

The future of ramie gland packing aligns with global sustainability trends:

- Development of fully biodegradable formulations

- Recycling programs for used packing materials

- Reduced water and energy consumption in manufacturing

- Lifecycle assessment tools for environmental impact measurement

Eng

Eng  русский

русский