The Ultimate Guide to Corrugated Metal Seals: Types, Installation, and Benefits

2025.10.09

2025.10.09

Industry News

Industry News

Corrugated metal roofing and siding are renowned for their durability and longevity. However, their performance is heavily dependent on one critical component: the seal. A proper corrugated metal seal is paramount for preventing leaks, blocking pests, and ensuring energy efficiency. This comprehensive guide delves into the world of seals for corrugated metal, exploring different types, their applications, and best practices for installation to ensure a watertight and long-lasting result.

What is a Corrugated Metal Seal?

A corrugated metal seal is a specialized component designed to close the gaps and voids inherent in corrugated metal profiles. These gaps occur at the ridge (the peak of the roof), along the eaves, at side laps where two panels meet, and around penetrations like pipes and vents. Seals are typically made from flexible, weather-resistant materials like EPDM rubber, PVC, or closed-cell foam, allowing them to conform to the metal's unique shape and withstand thermal expansion and contraction.

- Primary Function: To create a continuous barrier against water, air, dust, and insect infiltration.

- Secondary Benefits: Improves thermal insulation, reduces noise from rain or wind, and prevents debris accumulation within the panel channels.

- Material Importance: The choice of material directly impacts the seal's lifespan and effectiveness in specific climates (e.g., UV resistance for sunny areas, flexibility for cold climates).

5 Essential Types of Seals for Corrugated Metal Roofing

Selecting the right seal is crucial for addressing specific points of potential leakage on a corrugated metal structure. Each type is engineered for a distinct location and purpose.

1. Corrugated Metal Ridge Cap Seal

The ridge is one of the most vulnerable areas on any roof. A corrugated metal ridge cap seal is a long, continuous strip installed under the ridge cap before it is screwed down. It fills the large, irregular gap between the cap and the crests of the corrugated panels on either side of the roof's peak.

- Purpose: Provides the primary defense against wind-driven rain and snow entering at the roof's highest point.

- Design: Often a "kork-n-seal" or bulb style that compresses to form a tight, resilient barrier.

- Installation Tip: Ensure the seal is not over-compressed, as this can cause the ridge cap to deform and reduce the seal's longevity.

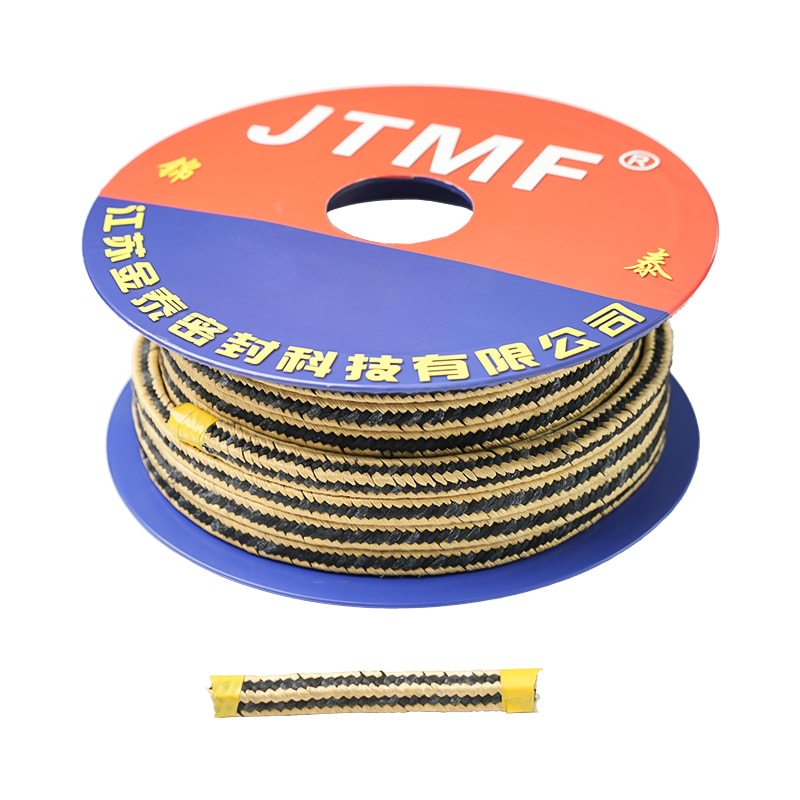

2. Corrugated Metal Roof Closure Strips

Closure strips are arguably the most common type of seal used. These are long, foam strips cut to match the specific profile of your corrugated metal. They are installed at the eave (bottom) and rake (sides) of the roof before the panels are placed.

- Purpose: To block open ends of the corrugated panels, preventing birds, insects, and leaves from nesting inside the channels and stopping wind from blowing up under the roof.

- Material: Typically made from closed-cell polyethylene foam, which is resistant to moisture absorption and compression set.

- Variations: Available in different densities; heavier-duty versions are used for high-wind or extreme weather areas.

3. How to Seal Corrugated Metal Roof Panels at Lap Joints

Where two corrugated panels overlap sideways (side laps), a small channel is created that can channel water if not properly sealed. Sealing these joints is a critical step in creating a monolithic roof surface.

- Method 1: Applying a continuous bead of a high-quality, UV-resistant sealant (like silicone or polyurethane) along the lap before joining the panels.

- Method 2: Using butyl rubber tape applied to the underlying panel before the overlapping panel is fastened down.

- Key Consideration: The sealing method must remain flexible to accommodate the natural movement of the metal panels without cracking or losing adhesion.

| Method | Best For | Pros | Cons |

| Liquid Sealant | Irregular gaps, complex joints | Excellent adhesion, fills all voids | Messy application, requires skill |

| Butyl Tape | Straight, uniform lap joints | Clean, consistent application, no mess | Less effective on uneven surfaces |

304ss/316ss Corrugated Metal Graphite Gasket

4. Best Sealant for Corrugated Metal Roof Penetrations

Vents, pipes, and HVAC units that protrude through the roof require meticulous sealing. The best sealant for corrugated metal roof penetrations is a high-performance elastomeric sealant designed for metal-to-other-material bonds.

- Ideal Properties: Look for sealants labeled for metal roofing that offer high elasticity, UV resistance, and waterproofing. Polyurethane and silicone-based sealants are top choices.

- Application Technique: Clean the area thoroughly. Apply sealant to the base of the penetration, then install a flashing boot over it. Seal the top and edges of the flashing with more sealant for a redundant seal.

- Product Note: Avoid cheap acrylic latex caulks, as they crack and fail quickly when exposed to sunlight and temperature swings on a metal roof.

5. DIY Corrugated Metal Sealing Tips and Tricks

For the avid DIYer, successfully sealing a corrugated metal roof is achievable with careful planning and the right techniques. A methodical approach will yield professional-level results and prevent costly callbacks.

- Surface Preparation is Key: All surfaces must be completely clean, dry, and free of dirt, oil, and rust. Use a wire brush and a cleaner/degreaser.

- Weather Matters: Apply sealants and install foam closures in dry conditions between 40°F (5°C) and 100°F (38°C). Extreme temperatures affect adhesion and curing.

- Don't Overdrive Fasteners: When installing panels over closure strips, drive screws straight and stop when the washer is snug against the metal. Over-driving compresses and crushes the foam, reducing its effectiveness.

- Inspect Annually: Perform a visual inspection of all seals, especially sealant at penetrations, once a year and re-apply as necessary.

FAQ

What is the longest-lasting sealant for corrugated metal?

High-quality, movement-grade polyurethane or silicone sealants are the longest-lasting options. They are specifically formulated to maintain elasticity and adhesion through extreme temperature fluctuations, UV exposure, and the natural expansion and contraction of metal. These elastomeric sealants can last 15-20 years or more, far outperforming standard acrylic caulks.

Can I use spray foam to seal my corrugated metal roof?

It is strongly discouraged to use expanding spray foam as a primary sealant on corrugated metal roofs. While it seems like an easy fix, it is not designed for this application. It can retain moisture against the metal, promoting rust, and lacks the necessary UV resistance, causing it to break down and crumble when exposed to sunlight. It is also incredibly difficult to remove for repairs. Always use products specifically designed for metal roofing systems.

How do I stop my corrugated metal roof from leaking at the overlaps?

Leaks at side lap joints are often due to improper sealing during installation or failed sealant. The permanent fix involves: 1. Carefully removing the fasteners from the overlapping panel. 2. Thoroughly cleaning both the top and underlying panel surfaces of all old sealant and debris. 3. Applying a new, generous bead of a premium polyurethane sealant to the underlying panel's high rib. 4. Immediately re-fastening the overlapping panel, ensuring screws are driven into the flat areas and not the sealed rib.

Do I need closure strips if I'm using insulation underneath?

Yes, closure strips and insulation serve two different purposes. Batt or board insulation provides thermal resistance (R-value) but is not designed to be an air or pest barrier. Closure strips are specifically designed to seal the open ends of the corrugated panels, creating a continuous barrier against wind, driven rain, and pests. For a fully optimized building envelope, you should use both insulation and the appropriate corrugated metal roof closure strips.

Eng

Eng  русский

русский