Graphite Gland Packing Installation and Maintenance Guide

2025.10.17

2025.10.17

Industry News

Industry News

Graphite gland packing is a critical sealing component used in rotating equipment like pumps and valves. Proper installation and maintenance are essential for optimal performance and longevity. This guide provides professional insights into handling this material effectively.

Pre-Installation Preparation for Graphite Gland Packing

Before installing graphite gland packing, thorough preparation ensures smooth operation. This phase involves inspecting components, selecting appropriate materials, and ensuring cleanliness to prevent premature failure.

- Check shaft or sleeve for wear and corrosion

- Verify packing ring dimensions match equipment specifications

- Clean stuffing box thoroughly to remove old packing residues

- Ensure proper alignment of rotating components

Tools and Safety Equipment Required

Having the right tools is crucial for efficient how to install graphite gland packing. Safety gear protects against graphite particles and ensures precise installation.

- Packing puller or extraction tool

- Clean rags and solvent for degreasing

- Calipers for measuring shaft and stuffing box dimensions

- Safety glasses and gloves

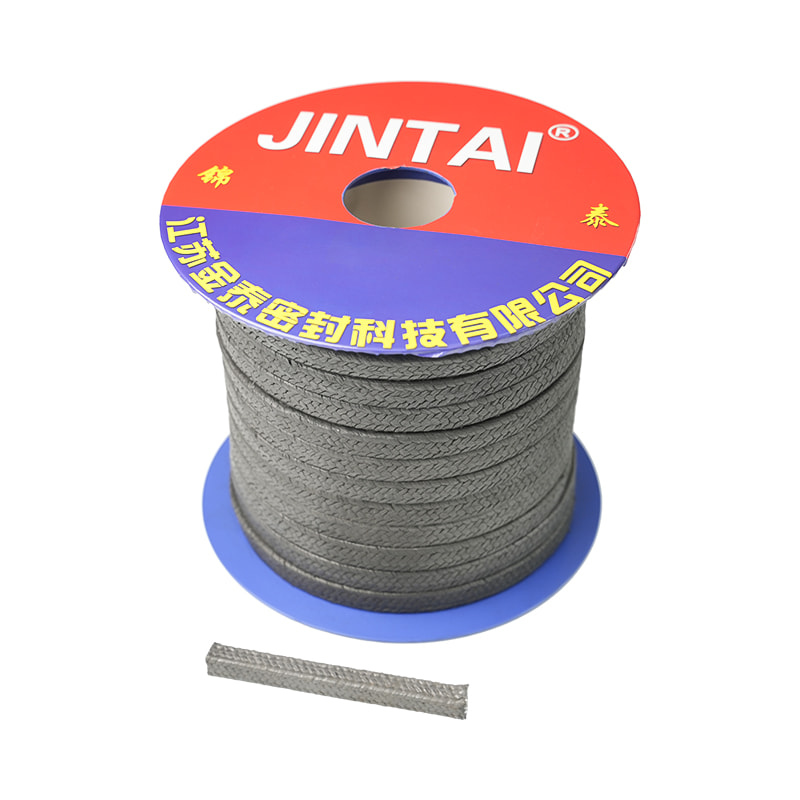

Mechanical/Water Pump PTFE Seal Packing Ramie Fiber Gland Packing

Step-by-Step Installation Process

Correct installation of graphite gland packing prevents leaks and extends service life. Follow these steps meticulously to achieve optimal sealing performance.

- Wrap packing loosely around shaft to determine cutting length

- Cut rings at 45-degree angles using sharp blade

- Stagger joints by 90 degrees between consecutive rings

- Tighten gland follower gradually after installation

Common Installation Mistakes to Avoid

Understanding graphite packing failure causes helps prevent operational issues. Avoid these common errors during installation.

| Over-tightening gland | Causes excessive friction and heat buildup |

| Incorrect ring cutting | Leads to leakage at joints |

| Using damaged rings | Compromises sealing integrity |

| Mixing old and new packing | Creates uneven compression |

Maintenance and Monitoring Techniques

Regular maintenance of graphite gland packing ensures reliable operation. Implement these techniques to maximize performance between replacements.

- Monitor leakage rate - 40-60 drops per minute is typically ideal

- Check temperature regularly using infrared thermometer

- Listen for unusual noises indicating excessive friction

- Document performance trends for predictive maintenance

Optimizing Graphite Packing Lifespan

Extending graphite packing lifespan tips reduces downtime and maintenance costs. These practices help achieve maximum service life.

| Proper run-in procedure | Gradual tightening over 24-48 hours |

| Adequate lubrication | Using compatible lubricants for specific media |

| Regular adjustment | Minor tightening as packing settles |

| Clean operating environment | Preventing abrasive particle ingress |

Troubleshooting Common Issues

When problems occur with graphite gland packing, systematic troubleshooting identifies root causes. Address these common issues promptly.

- Excessive leakage often indicates need for adjustment or replacement

- Overheating suggests overtightening or inadequate lubrication

- Shaft wear points to misalignment or abrasive contamination

- Short service life may stem from chemical incompatibility

High Temperature Graphite Packing Solutions

For applications involving elevated temperatures, high temperature graphite packing requires special considerations. These solutions address thermal challenges.

- Select reinforced graphite grades for temperatures above 500°F

- Allow additional clearance for thermal expansion

- Implement cooling flushes for extreme temperature applications

- Monitor thermal cycling effects on packing compression

FAQ

What is the maximum temperature for graphite gland packing?

Graphite gland packing typically withstands temperatures up to 600°F (315°C) in oxidizing atmospheres and up to 1200°F (650°C) in inert environments. For high temperature graphite packing applications, specialized reinforced grades can extend this range. Jiangsu Jintai Sealing Technology Co., Ltd. develops advanced materials tested under extreme conditions to ensure reliability.

How often should graphite packing be replaced?

Replacement intervals for graphite gland packing vary based on operating conditions. Generally, expect 6-24 months of service with proper maintenance. Following graphite packing lifespan tips like correct run-in procedures and regular adjustments can maximize service life. Monitoring leakage rates and temperature provides indicators for replacement timing.

What causes graphite packing to fail prematurely?

Common graphite packing failure causes include chemical incompatibility, improper installation, shaft misalignment, and abrasive media. Understanding these factors helps prevent unexpected downtime. Jiangsu Jintai Sealing Technology Co., Ltd. conducts rigorous testing to identify failure mechanisms and develop more durable solutions.

Can graphite packing be used in food processing equipment?

Yes, specific grades of graphite gland packing are manufactured to meet food-grade standards. These materials use high-purity graphite without additives that could contaminate products. When selecting packing for food applications, verify compliance with relevant regulations and consider graphite packing for pumps in sanitary designs.

How do I select the right graphite packing for my application?

Selecting appropriate graphite gland packing requires evaluating operating parameters including temperature, pressure, shaft speed, and chemical exposure. For specific applications like graphite packing for pumps versus valves, consider differences in dynamic motion. Jiangsu Jintai Sealing Technology Co., Ltd. offers technical support to match their Nofstein brand products to application requirements.

Eng

Eng  русский

русский