Pros and Cons of Graphite and Asbestos Packing: Selection and Risks Under High Temperature and High Pressure

2025.10.02

2025.10.02

Industry News

Industry News

In the demanding world of industrial sealing, selecting the right material for valve stems, pumps, and agitators is critical for safety, efficiency, and cost-effectiveness. Among the various options, graphite gland packing and asbestos-based packings represent two significant chapters in engineering history. While asbestos was once the industry standard, health and environmental concerns have led to the rise of advanced alternatives like graphite. This comprehensive guide delves into the advantages, disadvantages, and critical selection criteria for these materials, especially when operating under extreme conditions of high temperature and high pressure. Understanding the properties and risks associated with each is paramount for engineers and maintenance professionals tasked with ensuring system integrity and personnel safety.

Understanding Graphite Gland Packing

Modern graphite gland packing is a high-performance sealing solution engineered to withstand some of the most challenging industrial environments. Composed of flexible graphite foil that is wound and compressed, it boasts exceptional thermal conductivity, chemical resistance, and self-lubricating properties. Unlike traditional twisted packings, graphite forms a robust seal that can adapt to minor shaft misalignments and wear. Its ability to perform reliably in temperatures ranging from cryogenic levels up to 4500°F (in inert atmospheres) makes it a versatile choice for extreme applications. The material is also chemically inert to most media, including acids, solvents, and steam, preventing degradation and ensuring a long service life. This combination of traits makes it an excellent choice for preventing leaks and reducing maintenance downtime in critical systems.

- Superior Thermal Stability: It maintains its structural integrity and sealing capabilities across an incredibly wide temperature spectrum, far surpassing many organic materials.

- Excellent Chemical Resistance: It is non-reactive with a vast array of corrosive process fluids, making it suitable for chemical processing industries.

- Self-Lubrication: The natural lubricity of graphite minimizes friction and wear on the shaft or stem, reducing power consumption and preventing damage to expensive equipment.

- Conformability: The flexible nature of graphite allows it to conform tightly to the shaft and stuffing box, creating a superior seal even on slightly imperfect surfaces.

The Legacy and Risks of Asbestos Packing

Historically, asbestos packing was the go-to material for sealing applications due to its innate resistance to heat, fire, and corrosion. It was cheap, readily available, and effective for sealing steam valves and other high-temperature equipment common in power plants and industrial facilities. However, the discovery of its severe health risks led to a dramatic shift in its use. When asbestos fibers become airborne during installation, removal, or maintenance, they can be inhaled and lodge in the lungs. This exposure is directly linked to serious, often fatal, diseases such as asbestosis, lung cancer, and mesothelioma. While some older facilities may still have equipment sealed with asbestos packing, its use is now heavily regulated or banned outright in many countries. The operational risks, coupled with immense liability and mandatory abatement costs, have made modern alternatives like graphite the standard.

- Proven Heat Resistance: Asbestos possesses excellent inherent thermal properties, capable of handling temperatures exceeding 1000°F.

- Significant Health Hazards: The material is a known human carcinogen, and handling it requires strict safety protocols and personal protective equipment (PPE).

- Environmental and Disposal Concerns: Disposing of asbestos packing is a complex and expensive process governed by strict environmental regulations.

- Legal and Liability Issues: Using asbestos today carries significant legal risk and potential liability for companies regarding employee health.

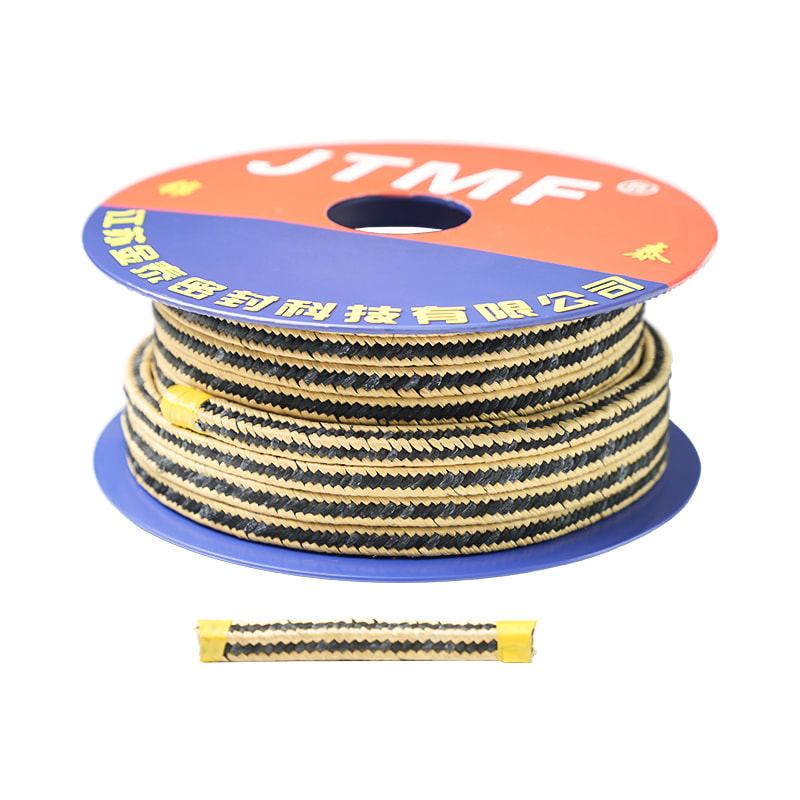

Cord Graphite Aramid Fiber Zebra Braided Gland Packing With Oil

Key Differences: Graphite vs. Asbestos Packing

When directly comparing graphite and asbestos packing, the differences extend far beyond just material composition. The choice between them involves a complex trade-off between historical performance, modern safety standards, and technical capabilities. Graphite excels in its versatility, safety profile, and performance in a wide range of chemical environments. Asbestos, while historically effective for heat, is now largely obsolete due to its irreversible health dangers. The following table provides a clear, side-by-side comparison of their key characteristics to aid in understanding why the industry has moved away from asbestos and towards advanced materials like graphite.

| Parameter | Graphite Packing | Asbestos Packing |

| Temperature Resistance | Excellent (Up to 4500°F in inert gas) | Excellent (Up to 1000°F+) |

| Chemical Resistance | Excellent against most acids and solvents | Good, but can be degraded by strong acids and alkalis |

| Health & Safety | Safe to handle, non-carcinogenic | Extreme hazard, carcinogenic |

| Environmental Impact | Inert, non-hazardous disposal | Hazardous, requires special disposal |

| Shaft Wear | Low (self-lubricating) | Can be higher, depending on lubrication |

| Regulatory Status | Widely accepted and recommended | Banned or heavily restricted |

Performance Under High Temperature and High Pressure

Extreme conditions of high temperature and high pressure are the ultimate test for any sealing material. In these environments, the intrinsic properties of graphite gland packing truly shine. Its exceptional thermal conductivity allows it to effectively transfer heat away from the shaft, preventing overheating and thermal degradation of the packing itself. This is a critical advantage over many other materials that can bake, harden, and fail. Furthermore, graphite's compressibility and recovery allow it to maintain a tight seal even as systems thermally cycle, expanding and contracting without losing sealing force. For high pressure graphite packing applications, it is often used in a die-formed ring configuration or reinforced with Inconel wire to resist extrusion and maintain seal integrity under immense pressure, preventing dangerous blowouts.

- Thermal Cycling Resilience: It can withstand repeated heating and cooling cycles without becoming brittle or losing its sealing ability.

- Heat Dissipation: Its high thermal conductivity protects both the packing and the shaft from heat damage.

- Extrusion Resistance: Reinforced grades are specifically designed to resist being forced out of the stuffing box under high pressure.

- Consistent Performance: Maintains stable friction and wear properties across the temperature range, ensuring predictable performance.

How to Choose the Right Packing Material

Selecting the appropriate gland packing is a systematic process that requires careful consideration of multiple operational factors. The goal is to find a material that provides effective sealing, maximizes equipment life, and minimizes maintenance needs, all while ensuring safety and compliance. The decision should never be based on a single factor like temperature or price alone. A holistic approach that evaluates the chemical environment, pressure, shaft speed, and equipment type is essential. For instance, a graphite packing for valves in a steam service will have different requirements than packing for a chemical pump handling abrasive slurries. This structured approach prevents premature failure, reduces downtime, and avoids costly mistakes.

- Process Media: Identify all chemicals, their concentrations, and phases (liquid, gas, slurry) the packing will contact.

- Temperature Range: Determine the minimum, maximum, and continuous operating temperatures.

- Pressure Range: Consider both static and dynamic pressure conditions the system experiences.

- Shaft/Sleeve Speed: Calculate the surface speed (PV value) to ensure the packing can handle the friction and heat generation.

- Equipment Type: Specify whether it's for a valve, centrifugal pump, mixer, or other equipment, as design varies.

- Regulatory & Safety Standards: Ensure the selected material complies with all local, national, and internal safety and environmental regulations.

Installation Best Practices for Longevity

Proper installation is just as critical as material selection for achieving a reliable and long-lasting seal. Incorrect installation can cause leakage, rapid wear, and shaft damage from the outset. The process begins with a clean stuffing box, free of old packing residue and debris. Each ring of graphite gland packing should be cut cleanly to size, typically using the wrap-around-the-shaft method, and each ring should be staggered so that the joints are 90 degrees apart. For a high temperature graphite seal, it is often recommended to pre-compress the rings in a die before installation to ensure optimal density. The gland follower should be tightened gradually and evenly, allowing the system to heat up and then retorquing after a few operational cycles to account for initial compression and thermal expansion.

- Meticulous Cleaning: Ensure the stuffing box and shaft are perfectly clean and smooth before installation.

- Precision Cutting: Cut each ring accurately to avoid gaps or overhangs that can cause leakage.

- Staggered Joints: Always offset the seams of each consecutive ring to prevent a direct path for leakage.

- Gradual Tightening: Tighten the gland nuts hand-tight initially, then gradually tighten further after the system is operational and hot to achieve the correct leak rate.

FAQ

What is the maximum temperature for graphite gland packing?

The maximum temperature for flexible graphite gland packing depends heavily on the operating atmosphere. In oxidizing environments (air), it can typically operate continuously at temperatures up to 900°F (480°C) without significant oxidation. However, in reducing or inert atmospheres (such as nitrogen or argon), it can perform remarkably at temperatures up to 4500°F (2500°C) as the lack of oxygen prevents oxidation. This makes it an ideal high temperature graphite seal for applications in inert gas environments, vacuum furnaces, and other extreme heat processes where most other materials would fail.

Is asbestos packing still legal to use?

The legality of asbestos packing varies by country and region, but its use is heavily restricted or completely banned in most developed nations, including the UK, Australia, and all member states of the European Union. In the United States, while a full ban is not in place, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) enforce extremely strict regulations on its handling, removal, and disposal. Using new asbestos packing is highly uncommon and poses severe legal liability and health risks. Most industries have transitioned to safer alternatives like graphite for all asbestos packing replacement needs.

How often should gland packing be replaced?

There is no single universal timeline for replacing gland packing, as it depends on numerous factors including the operating conditions, the material used, and the equipment. A well-installed graphite packing for pumps in a clean, moderate service can last for several years. The primary indicator for replacement is an increase in leakage that cannot be controlled by gently tightening the gland follower. Other signs include a noticeable increase in power consumption (due to high friction), excessive shaft wear, or the packing becoming hard and brittle. Implementing a predictive maintenance program that includes regular inspection is the best way to determine the optimal replacement interval for your specific application.

Can graphite packing be used on mixers and agitators?

Absolutely. Graphite gland packing is an excellent choice for sealing mixers and agitators, which often experience significant shaft runout and deflection. Its superior flexibility and conformability allow it to maintain a stable seal even with these dynamic movements. For these applications, it is often supplied in a die-formed ring style for easy installation and consistent density. For particularly abrasive slurries or severe services, a grade reinforced with corrosion-resistant wire (like 316 stainless or Inconel) is recommended to provide added strength and resist extrusion, ensuring a long and reliable service life in challenging mixing duties.

What are the signs of failing gland packing?

Recognizing the early signs of failing gland packing can prevent catastrophic equipment damage and unplanned downtime. The most common indicator is a consistent drip rate that increases over time and can no longer be adjusted by the gland follower. Other warning signs include visible smoke or steam coming from the stuffing box, indicating excessive heat generation from friction. A scorched or hardened appearance of the packing, excessive vibration of the pump or valve, and a noticeable increase in the motor's amperage (signaling higher drag) are all clear signals that the packing requires attention, either through adjustment or complete asbestos packing replacement with a modern material like graphite.

Eng

Eng  русский

русский