Application Advantages of Graphite Gland Packing in Chemical Industry

2025.10.24

2025.10.24

Industry News

Industry News

- 1 Chemical Resistance Properties of Graphite Gland Packing

- 2 High-Temperature Performance in Chemical Processes

- 3 Cost-Efficiency and Maintenance Benefits

- 4 Environmental and Safety Advantages

- 5 Selection Guidelines for Chemical Applications

- 6 FAQ

- 6.1 How does graphite packing perform with strong oxidizing agents?

- 6.2 What makes graphite more cost-effective than PTFE in chemical applications?

- 6.3 Can graphite packing handle abrasive chemicals in slurry applications?

- 6.4 How does temperature affect graphite packing selection for chemical pumps?

- 6.5 What are the installation considerations for graphite packing in chemical service?

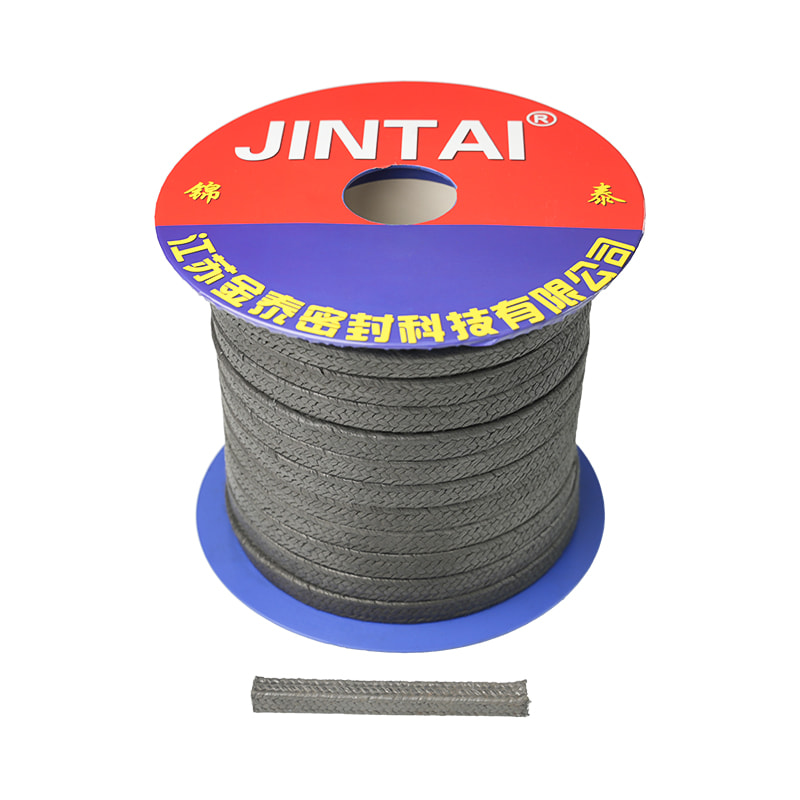

Graphite gland packing has become an essential sealing solution in chemical processing environments due to its exceptional performance under challenging conditions. This specialized material offers unique benefits that address the stringent requirements of chemical applications, from corrosive media handling to high-temperature operations.

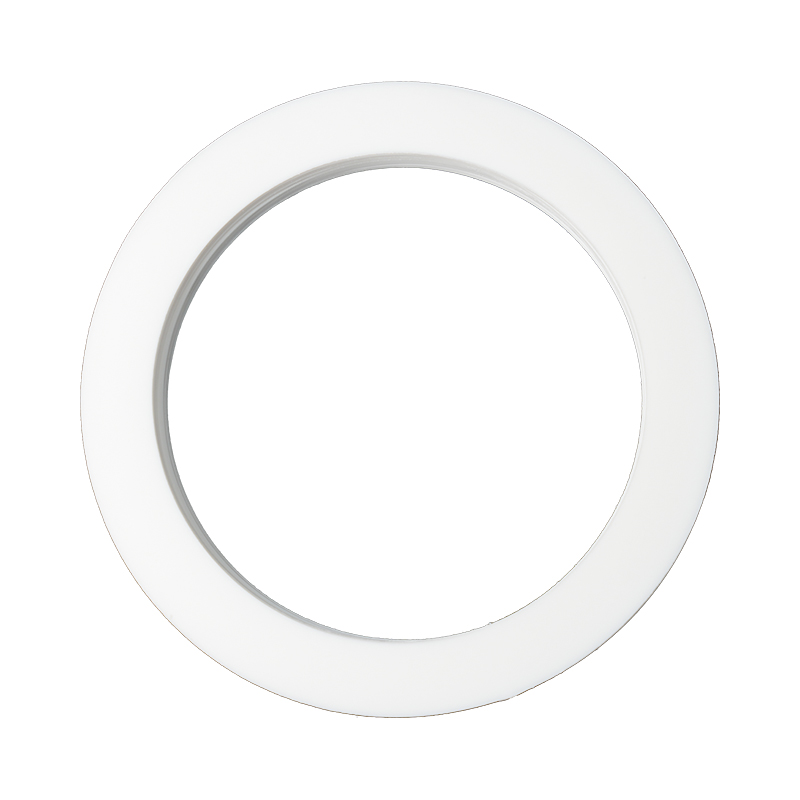

Mechanical/Water Pump PTFE Seal Packing Ramie Fiber Gland Packing

Chemical Resistance Properties of Graphite Gland Packing

The inherent chemical resistance of graphite packing makes it particularly suitable for chemical industry applications where exposure to aggressive media is common. Graphite maintains structural integrity when exposed to most acids, alkalis, and organic solvents, providing reliable sealing performance where other materials would degrade.

- Excellent resistance to mineral acids including sulfuric, hydrochloric, and nitric acid

- Stable performance in alkaline environments up to pH 14

- Compatibility with organic solvents and hydrocarbon-based chemicals

- Minimal swelling or degradation when exposed to chemical media

Comparison with Alternative Sealing Materials

When evaluating graphite vs PTFE packing for chemical applications, each material offers distinct advantages. Understanding these differences helps engineers select the optimal solution for specific chemical processing conditions.

| Temperature resistance | Graphite: Up to 650°C in inert atmosphere | PTFE: Maximum 260°C continuous |

| Chemical compatibility | Graphite: Resists most chemicals except strong oxidizers | PTFE: Nearly universal chemical resistance |

| Thermal conductivity | Graphite: Excellent heat dissipation | PTFE: Poor thermal conductor |

| Compression recovery | Graphite: Maintains seal under thermal cycling | PTFE: Subject to cold flow and compression set |

High-Temperature Performance in Chemical Processes

Chemical manufacturing often involves elevated temperatures where graphite packing for chemical pumps demonstrates superior performance. The material's ability to maintain sealing integrity at high temperatures prevents leaks and ensures operational safety in critical processes.

- Maintains structural stability up to 650°C in oxidizing atmospheres

- Provides consistent sealing performance during thermal cycling

- Reduces the risk of packing hardening and shaft damage

- Minimizes friction and heat generation through self-lubricating properties

Applications in Specific High-Temperature Processes

The thermal stability of high temperature graphite packing makes it ideal for various chemical industry applications where heat management is critical to process efficiency and safety.

| Distillation columns | Sealing agitator shafts in high-temperature separation processes |

| Reactor vessels | Maintaining seal integrity during exothermic reactions |

| Heat transfer systems | Sealing pumps handling hot thermal fluids |

| Incineration processes | Reliable performance in waste treatment applications |

Cost-Efficiency and Maintenance Benefits

Implementing cost-effective graphite packing solutions in chemical plants significantly reduces total ownership costs through extended service life and reduced maintenance requirements. The long-term economic benefits make graphite an attractive choice for budget-conscious operations.

- Extended replacement intervals compared to organic fiber packings

- Reduced downtime for maintenance and repacking

- Lower inventory requirements due to broad application range

- Decreased water consumption for flush systems in high-temperature applications

Lifecycle Cost Analysis

When evaluating cost-effective graphite packing solutions, considering the total lifecycle cost provides a more accurate comparison than initial purchase price alone. Graphite packing often demonstrates superior value over extended operational periods.

| Initial material cost | Higher than basic synthetic fibers | Lower than specialized high-performance materials |

| Installation frequency | Lasts 3-5 times longer than standard packings | Reduces labor and downtime costs |

| Energy consumption | Lower friction reduces power requirements | Improves overall pump efficiency |

| Equipment protection | Minimizes shaft wear | Extends equipment service life |

Environmental and Safety Advantages

In today's regulatory environment, graphite gland packing offers significant environmental and safety benefits that align with chemical industry sustainability initiatives. These advantages contribute to safer working conditions and reduced environmental impact.

- Asbestos-free composition eliminates health hazards associated with traditional packing materials

- Reduced leakage minimizes chemical emissions to the environment

- Compatibility with environmental regulations and industry standards

- Lower fugitive emissions support compliance with clean air regulations

Meeting Industry Standards and Regulations

Modern graphite packing for chemical pumps is designed to comply with increasingly stringent industry standards and environmental regulations, providing chemical plants with sealing solutions that support regulatory compliance.

| Fugitive emission standards | Meets requirements for low leakage rates in volatile service |

| Material safety | Compliant with RoHS and REACH regulations |

| Industry certifications | Approved for use in regulated chemical processes |

| Quality assurance | Manufactured under strict quality control systems |

Selection Guidelines for Chemical Applications

Choosing the appropriate graphite gland packing requires careful consideration of specific application parameters to ensure optimal performance and longevity in chemical service conditions.

- Evaluate chemical compatibility with process media, including trace components

- Consider temperature ranges including thermal cycling conditions

- Assess pressure and velocity parameters for the specific equipment

- Review equipment design including shaft surface finish and stuffing box dimensions

Application-Specific Recommendations

Different chemical processes require tailored approaches to graphite packing selection to address unique operational challenges and ensure reliable sealing performance.

| Corrosive service | Pure graphite without metallic reinforcement | Avoids galvanic corrosion |

| Abrasive slurries | Reinforced graphite with appropriate fillers | Enhanced wear resistance |

| High-speed equipment | Flexible graphite with controlled density | Balanced friction characteristics |

| Food and pharmaceutical | High-purity medical grade graphite | Meets sanitary requirements |

FAQ

How does graphite packing perform with strong oxidizing agents?

Graphite gland packing has limitations when handling strong oxidizing agents such as nitric acid, chromic acid, or concentrated sulfuric acid above certain temperatures. Under these conditions, graphite can oxidize, leading to reduced service life. For applications involving strong oxidizers, specialized packing materials or additional protective measures may be necessary. Jiangsu Jintai Sealing Technology Co., Ltd. offers technical guidance on material selection for challenging chemical environments.

What makes graphite more cost-effective than PTFE in chemical applications?

When comparing graphite vs PTFE packing for chemical use, graphite typically offers longer service life in high-temperature applications, better thermal conductivity that reduces heat buildup, and superior recovery after thermal cycling. While PTFE has broader chemical resistance, graphite's performance advantages in specific chemical industry applications often result in lower total cost of ownership through reduced maintenance frequency and downtime.

Can graphite packing handle abrasive chemicals in slurry applications?

Standard graphite gland packing may experience accelerated wear when handling abrasive slurries. However, reinforced graphite packing with appropriate filler materials can provide satisfactory service in moderately abrasive applications. For highly abrasive chemical slurries, alternative solutions or additional protective measures such as hardened sleeves may be recommended. The extensive experience of Jiangsu Jintai Sealing Technology Co., Ltd. in diverse industrial applications enables them to provide tailored recommendations for challenging conditions.

How does temperature affect graphite packing selection for chemical pumps?

Temperature significantly influences the selection of graphite packing for chemical pumps. While graphite generally performs well at elevated temperatures, the specific chemical environment must be considered. In oxidizing atmospheres, temperature limits are lower than in inert or reducing environments. Additionally, thermal expansion characteristics must align with equipment design to maintain proper sealing compression across operating temperature ranges.

What are the installation considerations for graphite packing in chemical service?

Proper installation of graphite gland packing in chemical applications requires attention to several critical factors: ensuring complete cleanliness of the stuffing box to prevent chemical contamination, using appropriate lubrication compatible with the process media, implementing correct ring staggering techniques to minimize leakage paths, and following proper run-in procedures to establish optimal packing configuration before full operation. Following manufacturer guidelines specific to chemical service ensures maximum performance and service life.

Eng

Eng  русский

русский