Graphite Gland Packing Structural Types and Functional Differences

2025.10.30

2025.10.30

Industry News

Industry News

- 1 Basic Structural Configurations of Graphite Packing

- 2 Reinforced Graphite Packing Varieties

- 3 Specialized Graphite Packing for Extreme Conditions

- 4 Functional Differences and Application Guidelines

- 5 Technical Specifications and Performance Data

- 6 FAQ

- 6.1 What are the main differences between braided and die-formed graphite packing?

- 6.2 How does reinforcement improve graphite packing performance?

- 6.3 What type of graphite packing is best for high-temperature applications above 500°C?

- 6.4 How do I select the right graphite packing density for my application?

- 6.5 Can graphite packing be used in food processing applications?

Graphite gland packing represents a critical category of sealing solutions with diverse structural configurations designed for specific operational requirements. Understanding the different types of graphite packing materials and their functional characteristics enables engineers to select optimal solutions for various applications, from standard pump sealing to demanding high-temperature services.

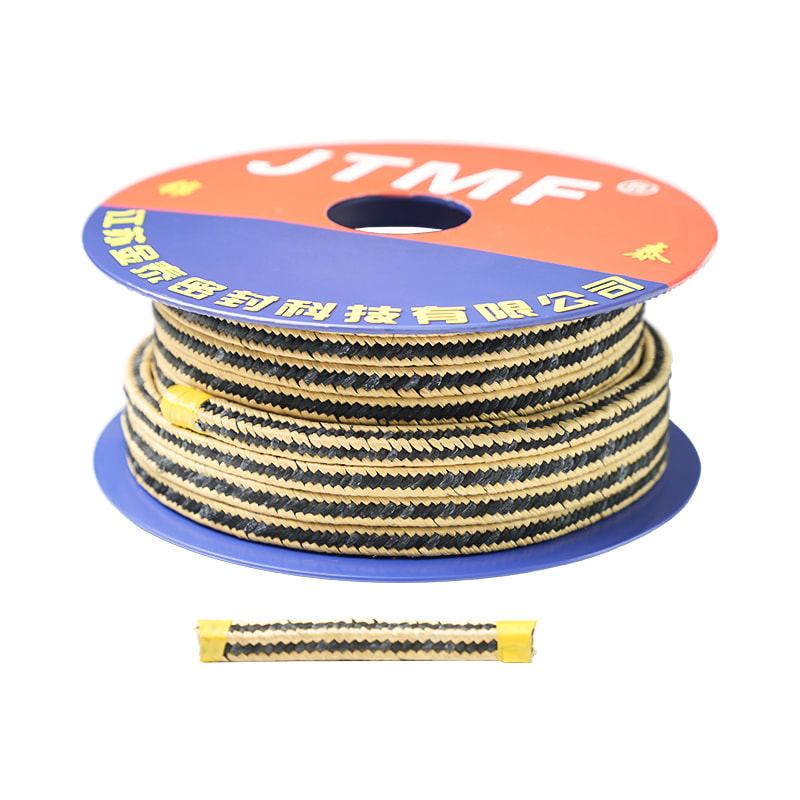

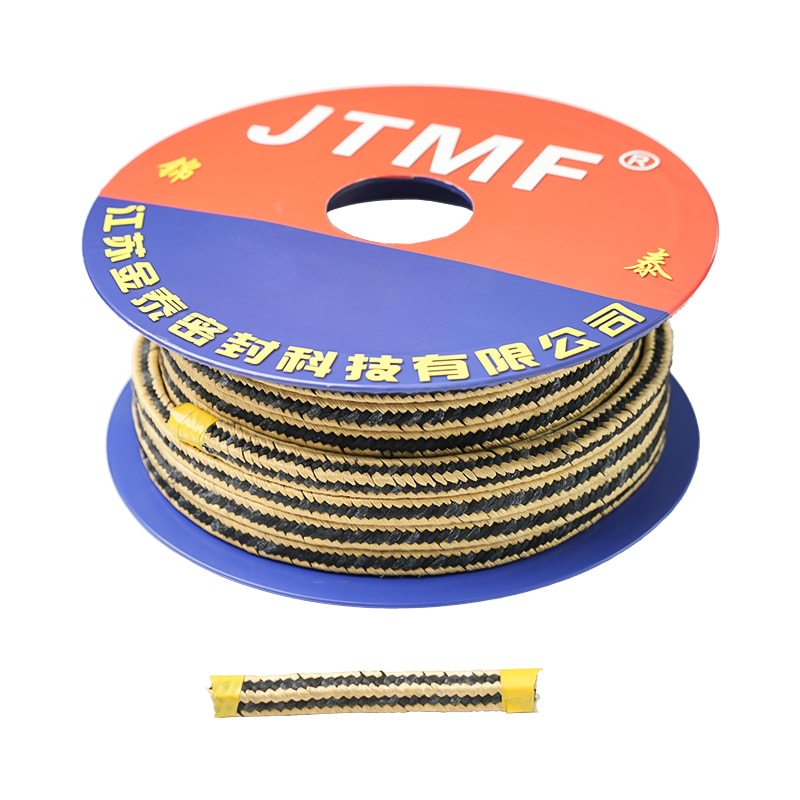

Cord Graphite Aramid Fiber Zebra Braided Gland Packing With Oil

Basic Structural Configurations of Graphite Packing

The fundamental architecture of graphite gland packing significantly influences its performance characteristics, installation methods, and application suitability. Different structural designs address specific operational challenges while maintaining the inherent benefits of graphite as a sealing material.

- Braided graphite packing with interwoven filament structure

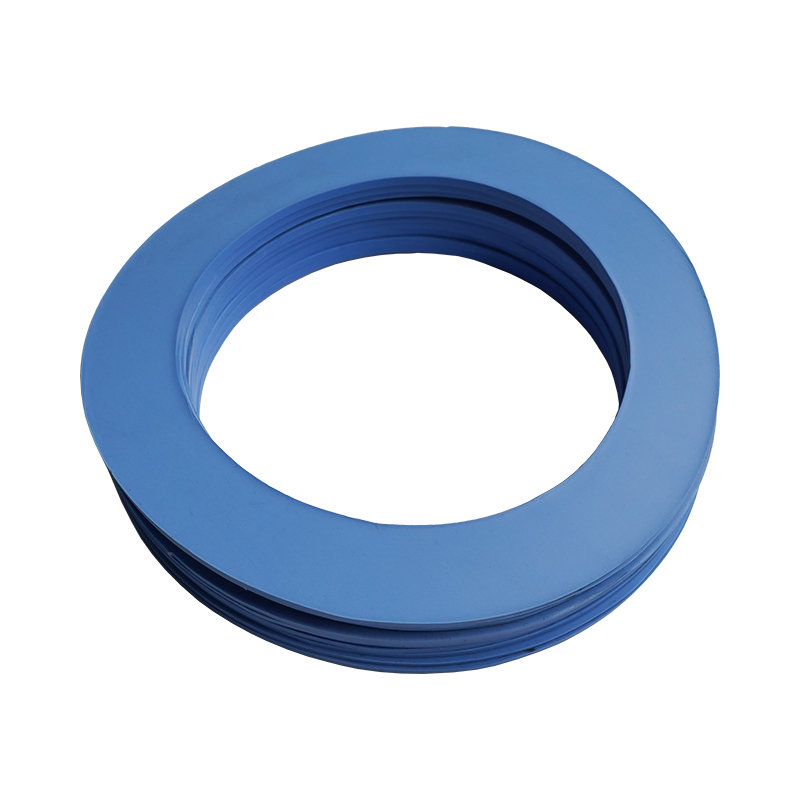

- Die-formed graphite rings with homogeneous composition

- Laminated graphite foil with layered construction

- Reinforced graphite composites with additional strength elements

Braided vs Die-Formed Graphite Packing

When comparing braided graphite packing specifications with die-formed alternatives, each manufacturing process creates distinct material properties that suit different operational environments and performance requirements.

| Manufacturing process | Graphite filaments woven into square or round cross-sections | Graphite powder compressed under high pressure into rings |

| Flexibility | High flexibility for easy installation around shafts | Limited flexibility, requires precise sizing |

| Density control | Variable density based on braiding tightness | Consistent, controlled density throughout |

| Applications | General purpose pumps, valves, and rotating equipment | High-temperature, high-pressure specialized services |

Reinforced Graphite Packing Varieties

Reinforced graphite packing incorporates additional materials to enhance specific performance characteristics while maintaining the fundamental benefits of graphite. These reinforced graphite packing benefits include improved strength, wear resistance, and application-specific performance enhancements.

- Inconel wire reinforced graphite for high-temperature stability

- Stainless steel reinforced graphite for corrosive environments

- Carbon fiber reinforced graphite for high-strength applications

- Aramid fiber reinforced graphite for improved abrasion resistance

Performance Enhancement Through Reinforcement

The strategic incorporation of reinforcement materials creates specialized types of graphite packing materials with enhanced capabilities for demanding industrial applications, extending the operational range beyond pure graphite limitations.

| Temperature limit increase | Up to 800°C with high-temperature alloys | Enables use in extreme heat applications |

| Tensile strength improvement | 300-500% strength increase with metal wires | Resists extrusion in high-pressure services |

| Wear resistance enhancement | Significantly reduced abrasion with fiber reinforcement | Extends service life in abrasive media |

| Chemical compatibility | Maintains graphite benefits while adding strength | Broadens application range |

Specialized Graphite Packing for Extreme Conditions

Advanced graphite packing for extreme temperatures incorporates specialized manufacturing techniques and material formulations to maintain sealing integrity under conditions that would compromise standard graphite packing performance.

- High-purity graphite with controlled ash content for nuclear applications

- Oxidation-resistant graphite with protective treatments

- Flexible graphite with enhanced recovery properties for thermal cycling

- Corrosion-resistant formulations for chemical industry applications

High-Temperature Performance Characteristics

Understanding the performance parameters of graphite packing for extreme temperatures requires examination of multiple material properties that collectively determine suitability for high-temperature sealing applications.

| Thermal conductivity | Excellent heat dissipation prevents localized overheating | Maintains seal integrity at elevated temperatures |

| Thermal expansion coefficient | Low, predictable expansion maintains sealing compression | Prevents loosening or over-compression during temperature changes |

| Oxidation resistance | Special formulations resist oxidative degradation | Extends service life in high-temperature air environments |

| Creep resistance | Maintains dimensional stability under load at high temperatures | Prevents gradual deformation and leakage |

Functional Differences and Application Guidelines

The functional performance of different graphite gland packing structures varies significantly, making proper selection critical for achieving optimal sealing performance, extended service life, and operational reliability across diverse industrial applications.

- Flexible graphite foil packing excels in valve stem applications with thermal cycling

- Braided graphite packing provides superior conformability for slightly eccentric shafts

- Die-formed rings offer consistent density for predictable high-pressure performance

- Reinforced varieties bridge performance gaps between graphite and other materials

Application-Specific Selection Criteria

Matching braided graphite packing specifications and other graphite packing types to specific application requirements ensures optimal performance while maximizing service life and minimizing maintenance requirements.

| Chemical processing pumps | Reinforced graphite with corrosion-resistant elements | Handles corrosive media with mechanical strength |

| Power generation valves | High-purity flexible graphite rings | Withstands thermal cycling and high temperatures |

| Marine applications | Braided graphite with enhanced seawater resistance | Provides reliable sealing in saltwater environments |

| Food and pharmaceutical | Certified pure graphite without additives | Meets sanitary requirements and regulations |

Technical Specifications and Performance Data

Comprehensive understanding of graphite packing specifications comparison enables engineers to make informed selection decisions based on quantifiable performance metrics rather than general material descriptions.

- Density ranges from 1.1 g/cm³ to 1.8 g/cm³ for different applications

- Compressibility varies from 15% to 45% based on structural configuration

- Recovery percentages from 35% to 85% after compression release

- pH resistance typically from 0 to 14 for most graphite varieties

Comparative Performance Metrics

Direct graphite packing specifications comparison across different structural types provides valuable insights for selection optimization based on specific operational parameters and performance requirements.

| Temperature range | -200°C to 650°C (oxidizing) | -200°C to 800°C (reinforced) | -200°C to 3000°C (inert) |

| Thermal conductivity | 50-150 W/m·K | 40-120 W/m·K | 80-400 W/m·K (axial) |

| Compression set | 15-25% | 10-20% | 5-15% |

| Chemical compatibility | Excellent except strong oxidizers | Varies with reinforcement | Pure graphite compatibility |

FAQ

What are the main differences between braided and die-formed graphite packing?

The primary differences between braided graphite packing and die-formed varieties lie in their manufacturing processes and resulting physical properties. Braided packing offers greater flexibility for easier installation on various shaft sizes and better conformability to minor equipment imperfections. Die-formed rings provide more consistent density throughout the material, which translates to more predictable sealing performance in high-pressure applications. Jiangsu Jintai Sealing Technology Co., Ltd. manufactures both types to address the full spectrum of industrial sealing requirements.

How does reinforcement improve graphite packing performance?

Reinforcement significantly enhances graphite packing by addressing its inherent limitations while preserving its beneficial properties. The reinforced graphite packing benefits include increased tensile strength to resist extrusion under high pressure, improved abrasion resistance for longer service life, enhanced structural integrity for easier installation and removal, and expanded temperature capabilities through the incorporation of high-temperature alloys. These improvements make reinforced graphite suitable for applications where pure graphite would be inadequate.

What type of graphite packing is best for high-temperature applications above 500°C?

For applications exceeding 500°C, specialized graphite packing for extreme temperatures is required. Die-formed high-purity graphite rings typically offer the best performance in these conditions due to their homogeneous structure and consistent thermal properties. For applications with additional mechanical stress, reinforced graphite with high-temperature alloy wires provides the necessary strength while maintaining thermal stability. The technical expertise of Jiangsu Jintai Sealing Technology Co., Ltd. ensures appropriate recommendations for specific high-temperature scenarios.

How do I select the right graphite packing density for my application?

Selecting the appropriate graphite packing density involves balancing multiple factors including operating pressure, shaft speed, and equipment condition. Lower density (1.1-1.4 g/cm³) graphite gland packing offers better conformability and is suitable for lower pressure applications or equipment with minor runout. Higher density (1.5-1.8 g/cm³) packing provides better extrusion resistance for high-pressure services but requires more precise installation. Consulting technical data sheets and application guidelines ensures optimal density selection.

Can graphite packing be used in food processing applications?

Yes, specific grades of graphite gland packing are suitable for food processing applications when they meet relevant regulatory standards. Food-grade graphite packing must be manufactured from high-purity materials without additives that could contaminate products. These specialized formulations maintain the excellent thermal and chemical resistance of standard graphite while complying with food safety regulations. Proper selection ensures both sealing performance and regulatory compliance in food industry applications.

Eng

Eng  русский

русский