Graphite Packing Installation and Maintenance Guide: Key to Extending Equipment Life

2025.09.18

2025.09.18

Industry News

Industry News

- 1 Introduction to Graphite Gland Packing

- 2 Step-by-Step Guide to Installing Graphite Gland Packing

- 3 Maintenance Tips for Prolonging the Life of Graphite Gland Packing

- 4 Understanding the Performance and Cost-Benefit of Graphite Gland Packing

- 5

- 6 FAQ

- 6.1 How do I choose the right graphite gland packing for my equipment?

- 6.2 What are the signs that my graphite gland packing needs maintenance?

- 6.3 Can graphite gland packing be used in high-pressure applications?

- 6.4 How do environmental factors affect the performance of graphite gland packing?

- 6.5 What are the common causes of graphite gland packing failure?

Introduction to Graphite Gland Packing

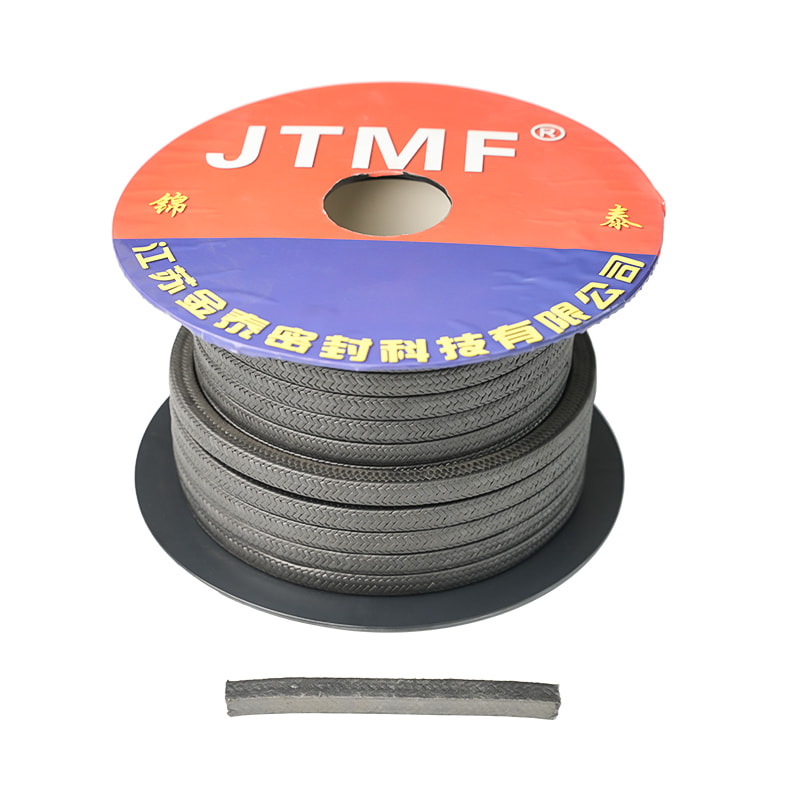

Graphite gland packing is a sealing material widely used in various industrial applications due to its excellent thermal stability, chemical resistance, and self-lubricating properties. It is commonly employed in pumps, valves, and other rotating equipment to prevent leakage of fluids or gases.

- What is graphite gland packing? It is a braided or extruded packing material made from flexible graphite, designed to provide a reliable seal in dynamic applications.

- Key advantages of using graphite gland packing:

- High-temperature resistance up to 1200°C in non-oxidative environments.

- Excellent chemical resistance to a wide range of acids, bases, and solvents.

- Self-lubricating properties reduce friction and wear on shafts.

- Low friction coefficient minimizes energy consumption.

- Common applications in industrial equipment:

- Pumps handling corrosive or high-temperature fluids.

- Valves in chemical processing industries.

- Rotary equipment in power generation plants.

- Sealing applications in food processing and pharmaceuticals.

Step-by-Step Guide to Installing Graphite Gland Packing

Proper installation of graphite gland packing is crucial to ensure optimal sealing performance and extend the lifespan of equipment. Follow these steps for effective installation:

- Preparation before installation:

- Ensure the equipment is shut down and depressurized.

- Remove any old packing and clean the stuffing box thoroughly.

- Measure the shaft diameter and stuffing box dimensions to determine the correct packing size.

- Installation process:

- Cut the graphite packing rings to the required length, ensuring the ends are square.

- Insert the first ring into the stuffing box, placing the joint at the bottom to prevent leakage.

- Continue inserting rings, staggering the joints to create a labyrinth seal.

- After all rings are installed, position the gland follower and tighten the gland nuts evenly to compress the packing.

- Post-installation checks:

- Start the equipment and monitor for any leakage.

- Adjust the gland nuts incrementally to achieve a slight drip, indicating proper sealing.

- Allow the packing to settle and re-tighten as necessary after a few hours of operation.

Maintenance Tips for Prolonging the Life of Graphite Gland Packing

Regular maintenance of graphite gland packing ensures continued sealing effectiveness and prevents premature equipment failure. Implement the following practices:

- Regular inspection and monitoring:

- Check for signs of leakage, overheating, or excessive wear.

- Monitor the gland temperature to ensure it remains within acceptable limits.

- Inspect the shaft for scoring or damage caused by packing.

- Adjusting packing to prevent leakage:

- If leakage increases, tighten the gland nuts slightly to compress the packing.

- Ensure not to over-tighten, as this can cause overheating and excessive wear.

- Maintain a slight drip to indicate proper sealing without excessive friction.

- Repacking procedures:

- When leakage persists despite adjustments, replace the packing rings.

- Follow the installation steps outlined above for proper repacking.

- Consider using higher-density graphite packing for improved sealing performance.

Understanding the Performance and Cost-Benefit of Graphite Gland Packing

Evaluating the performance and cost-effectiveness of graphite gland packing helps in making informed decisions for equipment maintenance:

- Sealing performance in various conditions:

- Provides effective sealing in high-temperature and high-pressure environments.

- Resistant to chemical attack from a wide range of substances.

- Offers low friction, reducing energy consumption and wear on equipment.

- Comparative analysis with other packing materials:

Material Temperature Resistance Chemical Resistance Friction Coefficient Graphite Gland Packing Up to 1200°C Excellent Low PTFE Packing Up to 260°C Good Moderate Aramid Packing Up to 280°C Good High - Long-term cost considerations:

- Higher initial cost but longer service life compared to other materials.

- Reduced maintenance and downtime costs due to improved sealing performance.

- Lower energy consumption resulting from reduced friction and wear.

Graphite PTFE Gland Packing Material Gland Seal Packing

FAQ

How do I choose the right graphite gland packing for my equipment?

Select graphite gland packing based on the operating conditions of your equipment, including temperature, pressure, and the nature of the fluid being sealed. Consult with manufacturers or sealing experts to determine the appropriate type and size.

What are the signs that my graphite gland packing needs maintenance?

Signs include increased leakage, overheating of the gland, excessive wear on the shaft, or a noticeable increase in energy consumption. Regular monitoring and inspection can help detect these issues early.

Can graphite gland packing be used in high-pressure applications?

Yes, graphite gland packing is suitable for high-pressure applications. However, ensure that the packing is properly reinforced and installed to withstand the pressure without compromising sealing performance.

How do environmental factors affect the performance of graphite gland packing?

Environmental factors such as temperature, pressure, and the presence of corrosive substances can impact the performance of graphite gland packing. Selecting the appropriate type of packing and regular maintenance can mitigate these effects.

What are the common causes of graphite gland packing failure?

Common causes include improper installation, over-tightening, inadequate lubrication, and exposure to incompatible chemicals or temperatures. Adhering to installation guidelines and maintenance procedures can significantly reduce the risk of failure and extend the life of the graphite gland packing.

- Improper installation: Misaligned or unevenly compressed packing can lead to leakage and wear.

- Over-tightening: Excessive compression increases friction and can damage the shaft.

- Incompatible chemicals: Exposure to substances beyond the chemical resistance of graphite packing can degrade material.

- High-temperature stress: Continuous exposure above recommended limits can reduce sealing efficiency.

- Lack of regular inspection: Failing to monitor gland condition can allow minor issues to become major problems.

Eng

Eng  русский

русский