Graphite Packing Applications and Performance Advantages: Versatile Applicability from Chemical to Marine Industries

2025.09.25

2025.09.25

Industry News

Industry News

- 1 Introduction to Graphite Gland Packing

- 2 Applications in Chemical Processing Industries

- 3 Marine Industry Applications

- 4 Performance Advantages of Graphite Gland Packing

- 5

- 6 FAQ

- 6.1 How do I choose the right graphite gland packing for my application?

- 6.2 What are the maintenance requirements for graphite gland packing?

- 6.3 Can graphite gland packing be used in food processing industries?

- 6.4 How does graphite gland packing compare to PTFE packing?

- 6.5 What are the environmental considerations when using graphite gland packing?

Introduction to Graphite Gland Packing

Graphite gland packing is a sealing material widely used in various industrial applications due to its excellent thermal stability, chemical resistance, and self-lubricating properties. It is commonly employed in pumps, valves, and other rotating equipment to prevent leakage of fluids or gases.

- What is graphite gland packing? It is a braided or extruded packing material made from flexible graphite, designed to provide a reliable seal in dynamic applications.

- Key properties and advantages:

- High-temperature resistance up to 1200°C in non-oxidative environments.

- Excellent chemical resistance to a wide range of acids, bases, and solvents.

- Self-lubricating properties reduce friction and wear on shafts.

- Low friction coefficient minimizes energy consumption.

- Common applications in various industries:

- Pumps handling corrosive or high-temperature fluids.

- Valves in chemical processing industries.

- Rotary equipment in power generation plants.

- Sealing applications in food processing and pharmaceuticals.

Applications in Chemical Processing Industries

In chemical processing industries, graphite gland packing is utilized for its ability to withstand extreme temperatures and aggressive chemicals. Its performance in such demanding environments ensures the integrity and efficiency of processing systems.

- High-temperature sealing in reactors and pumps:

- Graphite gland packing maintains a reliable seal in high-temperature reactors, preventing leaks and ensuring safe operation.

- Its thermal conductivity helps dissipate heat, reducing the risk of overheating and equipment failure.

- Resistance to aggressive chemicals and solvents:

- Graphite's chemical resistance allows it to withstand exposure to a wide range of corrosive substances without degrading.

- This property extends the lifespan of sealing components and reduces maintenance costs.

- Case studies and industry examples:

- In a case study, the use of graphite gland packing in a chemical processing plant led to a 40% reduction in seal failures, enhancing operational efficiency and safety.

Marine Industry Applications

In the marine industry, graphite gland packing plays a crucial role in sealing marine propulsion systems, ensuring the safe and efficient operation of vessels.

- Sealing in marine propulsion systems:

- Graphite gland packing provides a reliable seal around propeller shafts, preventing seawater ingress and maintaining vessel buoyancy.

- Its self-lubricating properties reduce friction, extending the lifespan of shaft components.

- Performance under seawater and salt exposure:

- Graphite's resistance to corrosion ensures the integrity of seals even in harsh marine environments.

- This durability reduces maintenance needs and enhances vessel reliability.

- Maintenance considerations and best practices:

- Regular inspection and adjustment of gland packing are essential to maintain optimal sealing performance.

- Proper lubrication and alignment of shaft components further extend the service life of the packing.

Performance Advantages of Graphite Gland Packing

The performance advantages of graphite gland packing make it a preferred choice in various industrial applications, offering enhanced efficiency and reliability.

- Thermal conductivity and high-temperature resistance:

- Graphite's high thermal conductivity allows it to effectively dissipate heat, preventing overheating and ensuring stable operation in high-temperature environments.

- Its resistance to temperatures up to 1200°C in non-oxidative conditions makes it suitable for extreme applications.

- Chemical resistance and durability:

- Graphite's excellent chemical resistance enables it to withstand exposure to a wide range of corrosive substances without degradation.

- This durability reduces the frequency of replacements and maintenance, leading to cost savings.

- Self-lubricating properties and low friction:

- Graphite's self-lubricating nature reduces friction between moving parts, minimizing wear and energy consumption.

- This property enhances the efficiency and lifespan of equipment, contributing to overall operational savings.

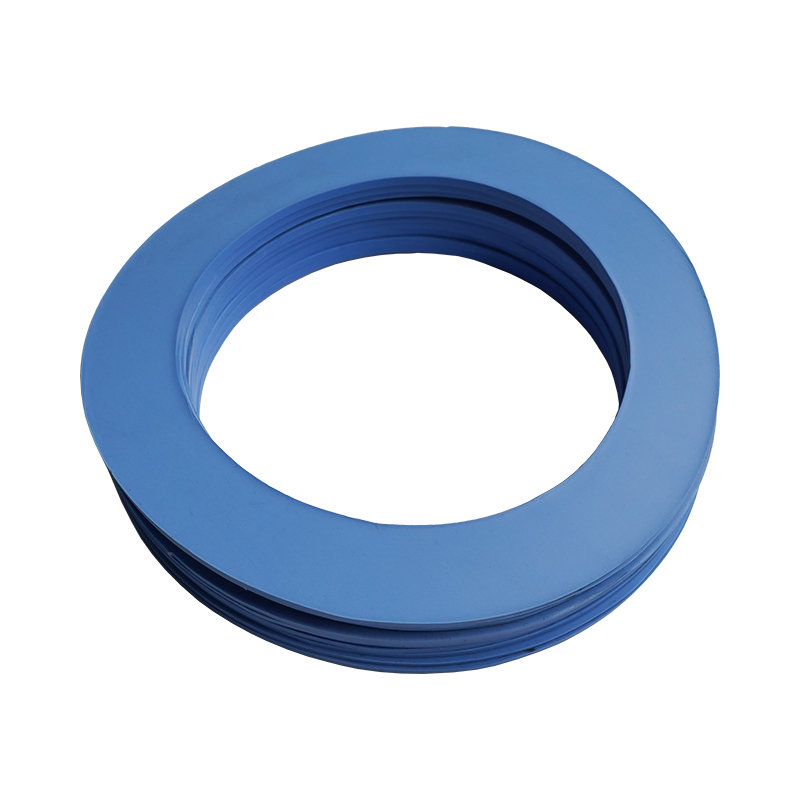

Pure Graphite Braided Gland Packing For Valves Pupm

FAQ

How do I choose the right graphite gland packing for my application?

Choosing the appropriate graphite gland packing involves considering factors such as operating temperature, pressure, chemical exposure, and shaft speed. Consulting with sealing experts and referring to manufacturer specifications can help in selecting the most suitable packing material.

What are the maintenance requirements for graphite gland packing?

Regular inspection and adjustment of gland packing are essential to maintain optimal sealing performance. Monitoring for signs of wear, leakage, and overheating can help in timely maintenance and replacement, ensuring the longevity of equipment.

Can graphite gland packing be used in food processing industries?

Yes, graphite gland packing can be used in food processing industries, provided it meets the necessary food-grade standards and does not contaminate the product. It's essential to ensure that the packing material complies with relevant regulations and certifications.

How does graphite gland packing compare to PTFE packing?

Graphite gland packing offers superior thermal conductivity and high-temperature resistance compared to PTFE packing. While PTFE is highly resistant to chemicals and has a low friction coefficient, graphite packing excels in extreme temperature and pressure conditions, making it suitable for high-demand applications.

What are the environmental considerations when using graphite gland packing?

Graphite gland packing is considered environmentally friendly due to its natural composition and durability, reducing the frequency of replacements and waste. However, it's essential to ensure proper disposal and recycling practices to minimize environmental impact.

Eng

Eng  русский

русский