High-Performance Gaskets: Key Types and Applications

2025.06.12

2025.06.12

Industry News

Industry News

Gaskets play a critical role in industrial sealing, ensuring leak-proof connections in high-pressure and high-temperature environments. Among the most reliable options are corrugated metal gaskets, metal-toothed gaskets, and spiral wound gaskets with metal cores. Each type offers unique advantages depending on the application.

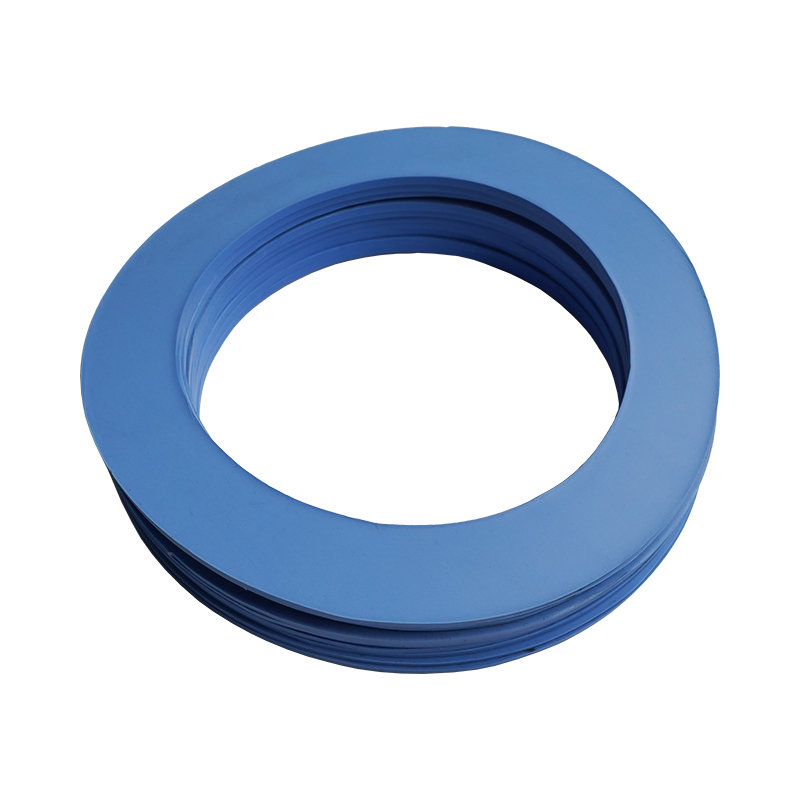

Stainless Steel Seal Ring Corrugated Metal Gasket Toothed Gasket

1. Corrugated Metal Gasket for High Pressure: Superior Sealing Under Extreme Conditions

Corrugated metal gaskets are designed for high-pressure applications, offering excellent resilience and sealing performance. Their wavy (corrugated) structure allows for better compression and recovery, making them ideal for:

Oil & gas pipelines (up to 10,000 psi)

Power generation systems (steam turbines, boilers)

Chemical processing plants (resistant to aggressive media)

Key Advantages:

Maintains seal integrity under thermal cycling

Higher pressure tolerance than flat gaskets

Suitable for irregular flange surfaces

Data Comparison:

| Feature | Corrugated Metal Gasket | Standard Flat Gasket |

|---|---|---|

| Max Pressure | 10,000 psi | 3,000 psi |

| Temperature Range | -200°C to +800°C | -50°C to +400°C |

2. Metal-Toothed Gasket for Flange Sealing: Enhanced Bite and Grip

Metal-toothed gaskets feature serrated edges that "bite" into flange surfaces, creating a strong mechanical seal. They are commonly used in:

High-vibration environments (pumps, compressors)

Flange connections in refineries

Applications requiring frequent disassembly

Key Advantages:

Prevents slippage under dynamic loads

Reusable in some configurations

Excellent for uneven flange surfaces

Performance Insight:

Withstands 15-20% higher bolt load than non-serrated gaskets

Reduces leakage risk in low-clamp-force installations

3. Spiral Wound Gasket with Metal Core: Flexibility and Reliability Combined

Spiral wound gaskets consist of alternating metal and filler layers, providing both flexibility and strength. The metal core (usually stainless steel) enhances stability, making them ideal for:

High-temperature steam systems

Chemical and petrochemical industries

ASME B16.20 compliant applications

Key Advantages:

Handles thermal expansion better than solid metal gaskets

Self-compensating for minor flange distortions

Long service life under cyclic pressure

Comparison with Solid Metal Gaskets:

| Factor | Spiral Wound Gasket | Solid Metal Gasket |

|---|---|---|

| Flexibility | High | Low |

| Reusability | Moderate | High |

| Cost Efficiency | Better for large diameters | More expensive |

Eng

Eng  русский

русский