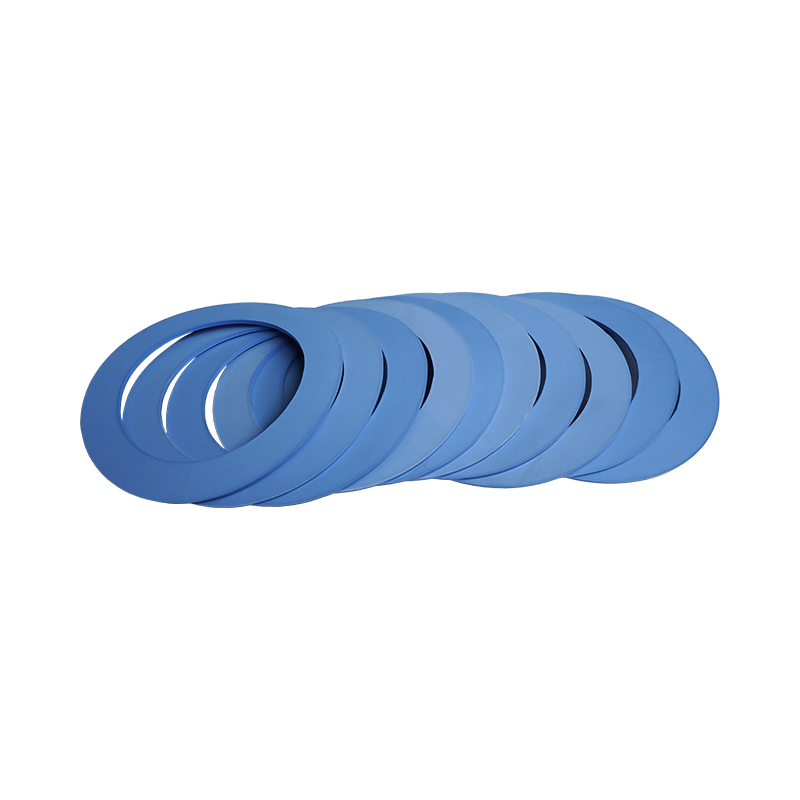

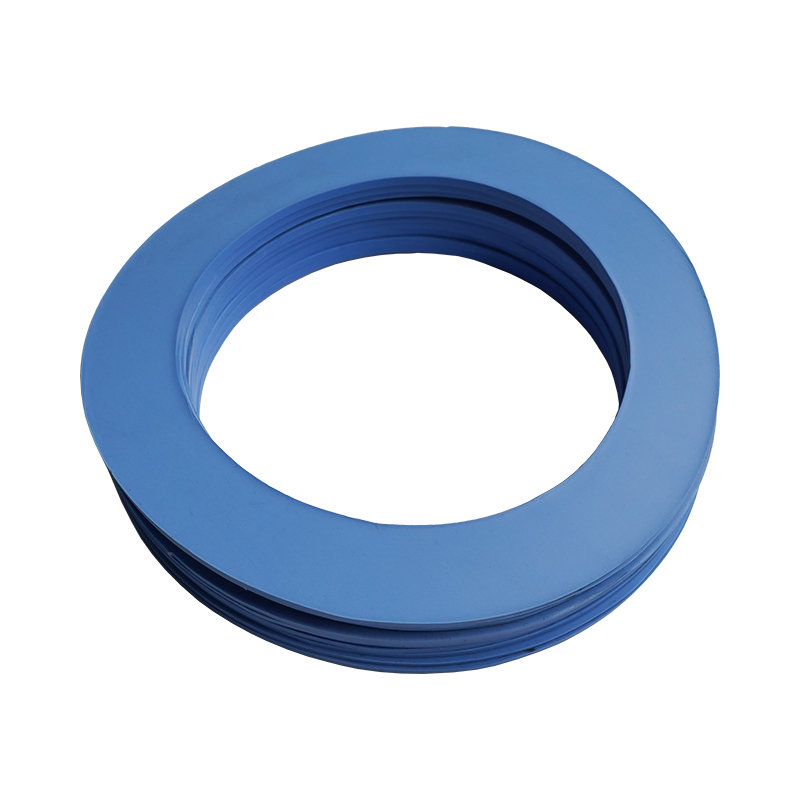

Non Metallic Gasket & Sheet Gasket: High-Performance Sealing Solutions for Industrial Applications

2025.06.05

2025.06.05

Industry News

Industry News

Sheet Gasket for High Temperature Applications: Best Materials and Uses

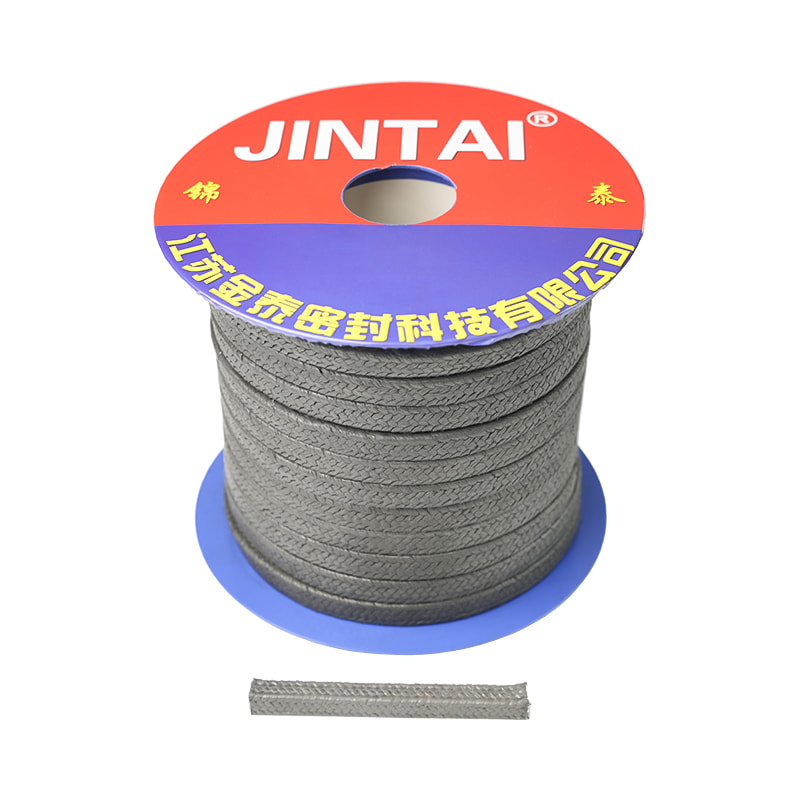

High-temperature environments demand durable sealing solutions to prevent leaks and ensure safety. Sheet gaskets made from materials like graphite, ceramic fiber, and PTFE excel in extreme heat. Graphite gaskets, for example, withstand temperatures up to 1000°C (1832°F) while maintaining flexibility. These gaskets are ideal for boilers, exhaust systems, and power plants. Choosing the right high-temperature sheet gasket ensures long-term reliability and reduces maintenance costs.

Best Sheet Gasket Material for Oil Resistance: Key Options

Oil-resistant gaskets must resist degradation from lubricants, fuels, and hydraulic fluids. Nitrile rubber (NBR), aramid fiber, and fluorocarbon (FKM) are top choices for oil resistance. Nitrile rubber gaskets offer excellent fuel and oil compatibility, while FKM provides superior chemical resistance. These materials are widely used in automotive, marine, and industrial machinery where oil exposure is constant. Selecting the right oil-resistant gasket prevents swelling, cracking, and leaks.

Non Metallic Gasket for Chemical Applications: Reliable Sealing in Harsh Environments

Chemical processing requires gaskets that resist acids, alkalis, and solvents. Non-metallic gaskets made from PTFE, EPDM, and compressed non-asbestos fiber (CNAF) provide excellent chemical resistance. PTFE gaskets, in particular, are nearly inert, making them ideal for pharmaceutical, petrochemical, and wastewater treatment plants. Unlike metallic gaskets, non-metallic options prevent galvanic corrosion and ensure a tight seal under varying pressures.

Soft Expanded Modified PTFE Sheet With Graphite, PTFE Teflon Sealing

Whether facing high temperatures, oil exposure, or aggressive chemicals, the right non-metallic gasket or sheet gasket enhances performance and safety. By selecting the optimal material for your application, you can improve efficiency, reduce downtime, and extend equipment lifespan. Explore these gasket solutions to meet your industrial sealing needs effectively.

Eng

Eng  русский

русский