Graphite Self-Sealing Technology: Applications and Benefits

2025.07.31

2025.07.31

Industry News

Industry News

- 1 Understanding Graphite Self-Sealing Gaskets and Their Industrial Uses

- 2 The Advantages of High Temperature Graphite Seals Over Conventional Materials

- 3 Flexible Graphite Packing Material for Rotating Equipment Applications

- 4 Implementing Graphite Sheet Thermal Management Solutions

- 5 The Science Behind Self-Lubricating Graphite Components

- 6 Future Developments in Graphite Sealing Technology

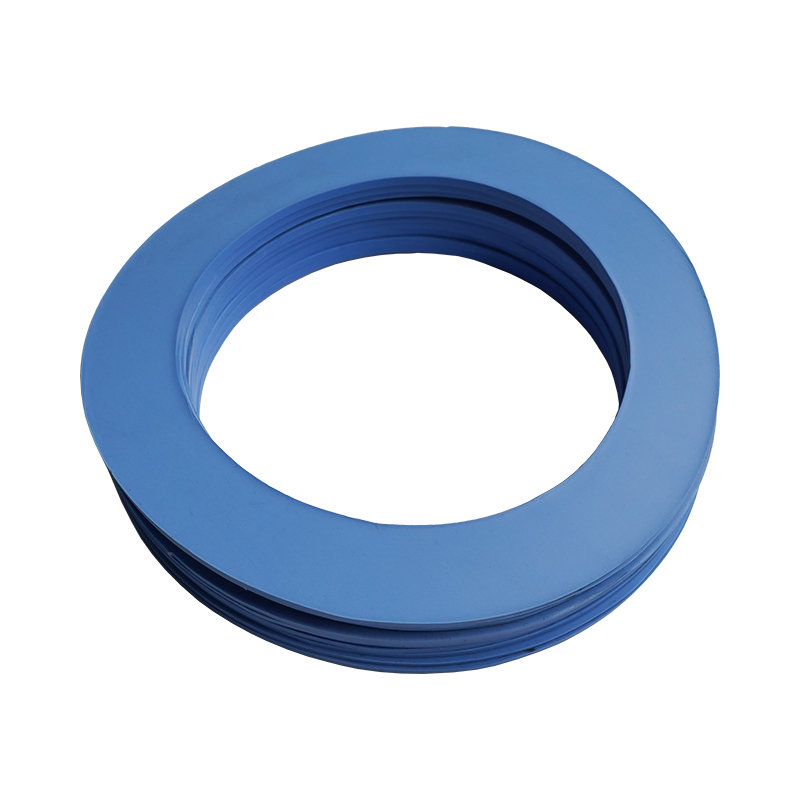

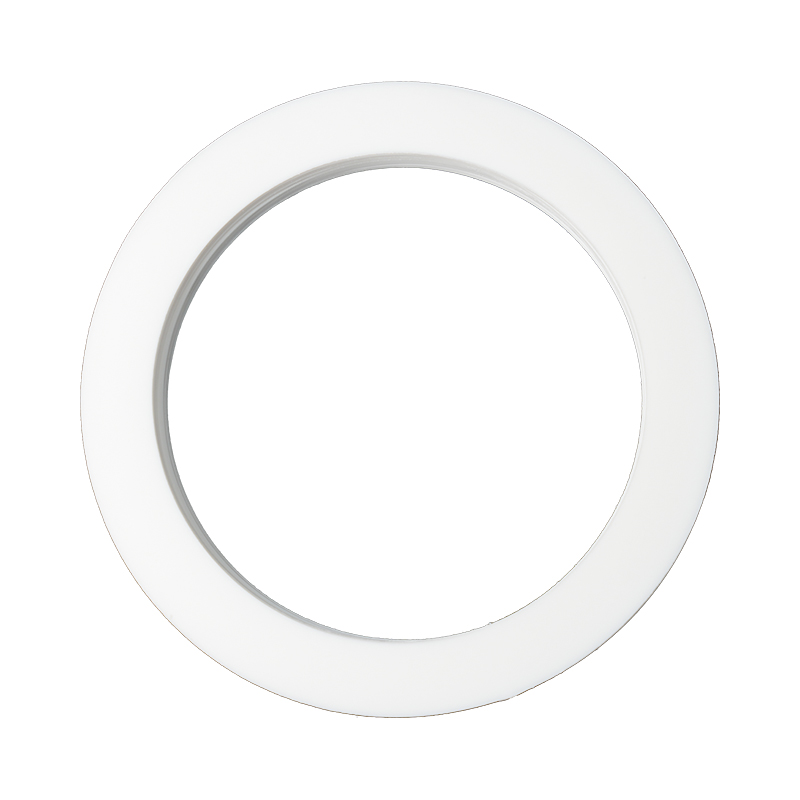

Understanding Graphite Self-Sealing Gaskets and Their Industrial Uses

Graphite self-sealing materials have revolutionized industrial sealing solutions by offering superior performance in high-temperature and high-pressure environments. Unlike traditional gasket materials, graphite self-sealing gaskets automatically compensate for flange irregularities and maintain tight seals even under extreme conditions.

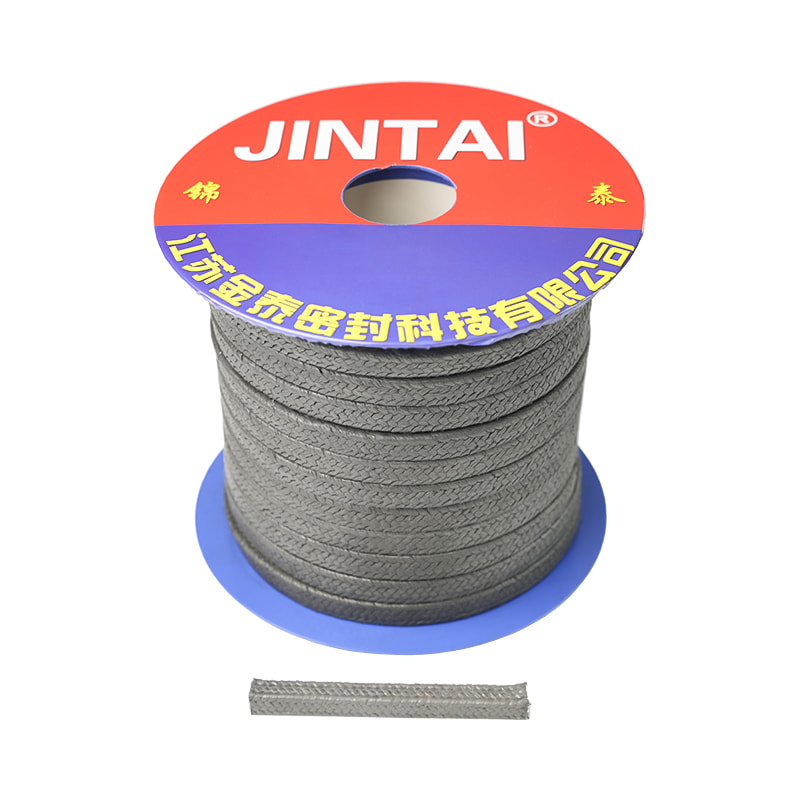

High Temperature Flexible Self Sealing Graphite Gasket With Corrosion

How Graphite Self-Sealing Works

The self-sealing mechanism in graphite gaskets occurs through several unique material properties:

- Flexible graphite layers conform to surface imperfections

- Thermal expansion creates additional sealing pressure

- Compression recovery maintains seal integrity during thermal cycling

- Chemical resistance prevents degradation from process fluids

Applications in Various Industries

Graphite self-sealing gaskets find applications across multiple sectors:

| Industry | Application | Benefits |

|---|---|---|

| Oil & Gas | Pipeline flanges, heat exchangers | Withstands high pressure and corrosive fluids |

| Power Generation | Steam turbine systems | Excellent thermal stability at extreme temperatures |

| Chemical Processing | Reactor vessels | Resistant to chemical attack |

The Advantages of High Temperature Graphite Seals Over Conventional Materials

When comparing high temperature graphite seals to traditional sealing materials, several key differences become apparent:

Temperature Performance Comparison

| Material | Maximum Continuous Temperature | Thermal Cycling Performance |

|---|---|---|

| Graphite | 450°C (842°F) in oxidizing, 3000°C (5432°F) in inert | Excellent - maintains seal through repeated cycles |

| Rubber | 120°C (248°F) typical | Poor - degrades with thermal cycling |

| PTFE | 260°C (500°F) | Fair - cold flow issues at high temperatures |

Long-Term Reliability Factors

The durability of high temperature graphite seals stems from several material characteristics:

- Oxidation resistance at elevated temperatures

- Minimal creep relaxation compared to polymer-based seals

- Maintenance of mechanical properties across wide temperature ranges

- Superior resistance to thermal shock

Flexible Graphite Packing Material for Rotating Equipment Applications

In pump and valve stem packing applications, flexible graphite packing material offers distinct advantages over traditional braided packing.

Installation and Performance Characteristics

Proper installation of graphite packing requires attention to several factors:

- Pre-compression of rings before installation

- Staggered joint alignment in multiple ring installations

- Proper gland follower loading to achieve optimal density

- Break-in procedures to establish proper sealing surface

Comparative Performance Metrics

| Parameter | Graphite Packing | Conventional Packing |

|---|---|---|

| Thermal Conductivity | High - dissipates frictional heat | Low - heat buildup issues |

| Compressibility | Excellent - conforms to shaft | Variable - depends on material |

| Chemical Resistance | Exceptional - inert to most chemicals | Material dependent |

Implementing Graphite Sheet Thermal Management Solutions

Graphite sheet thermal management has become increasingly important in electronics, aerospace, and energy applications due to its unique combination of properties.

Key Properties for Thermal Applications

- Anisotropic thermal conductivity (high in-plane, low through-plane)

- Lightweight compared to metal heat spreaders

- Conformability to uneven surfaces

- Electrical insulation properties

Design Considerations

When implementing graphite thermal solutions, engineers must consider:

- Orientation of the sheet relative to heat flow

- Interface materials and thermal contact resistance

- Mechanical protection of the fragile sheets

- Environmental factors affecting long-term performance

The Science Behind Self-Lubricating Graphite Components

Self-lubricating graphite components provide maintenance-free operation in applications where conventional lubricants fail.

Mechanisms of Self-Lubrication

Graphite's lubricating properties originate from its crystalline structure:

- Lamellar structure allows easy shear between basal planes

- Adsorbed moisture films enhance lubricity

- Transfer films develop on counterfaces

- Debris particles act as rolling elements

Performance in Extreme Environments

| Environment | Graphite Performance | Alternative Materials |

|---|---|---|

| High Vacuum | Excellent - no outgassing | Most lubricants fail |

| High Radiation | Good - maintains structure | Polymers degrade |

| Cryogenic | Fair - reduced lubricity | Liquids solidify |

Future Developments in Graphite Sealing Technology

The field of graphite-based sealing continues to evolve with new material formulations and applications.

Emerging Trends and Innovations

- Hybrid materials combining graphite with other advanced materials

- Nanostructured graphite for enhanced properties

- Additive manufacturing of complex graphite components

- Improved oxidation resistance coatings

Challenges and Opportunities

While graphite sealing solutions offer numerous benefits, some challenges remain:

- Cost considerations for high-performance grades

- Handling and installation requirements

- Material limitations in certain chemical environments

- Need for standardized testing methodologies

Eng

Eng  русский

русский