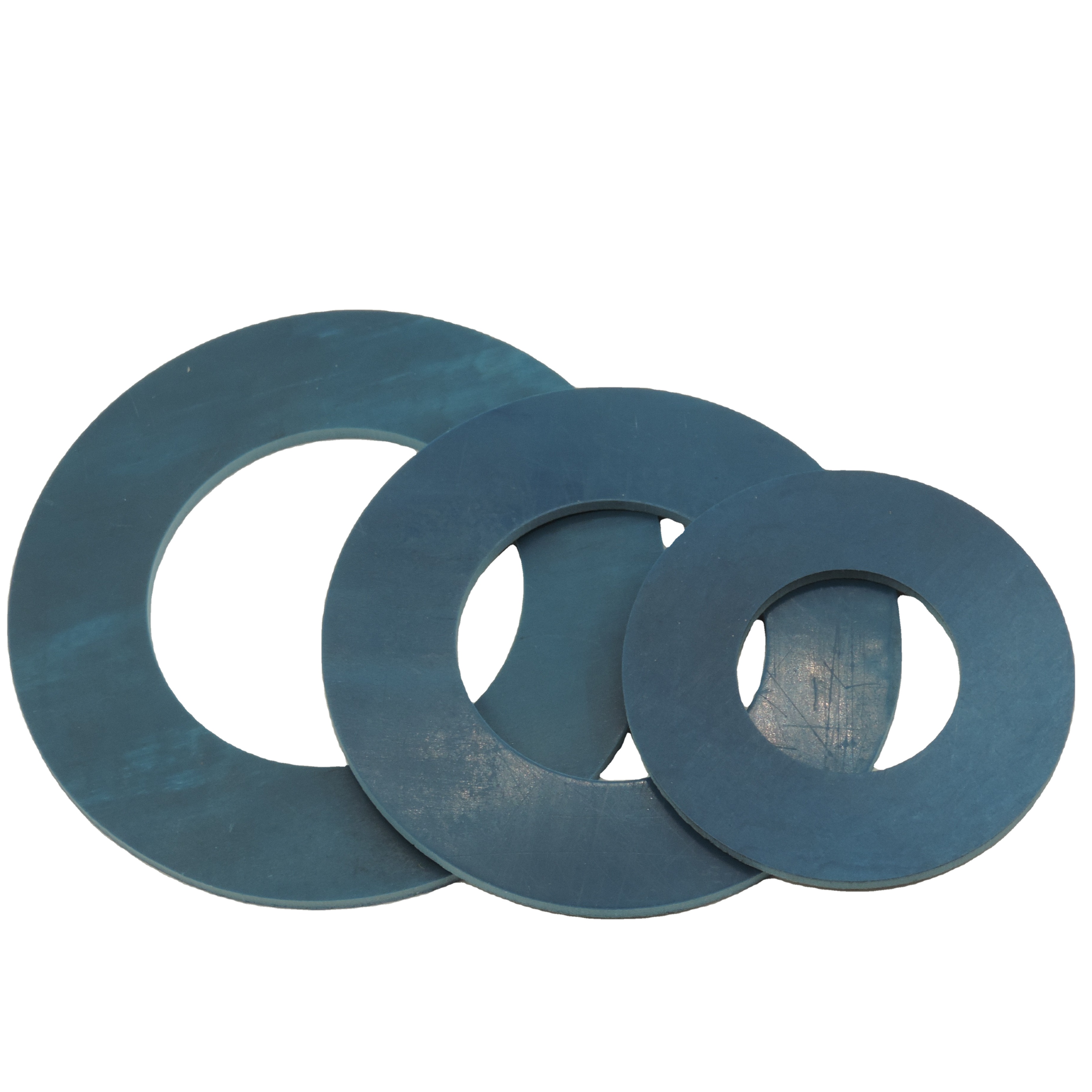

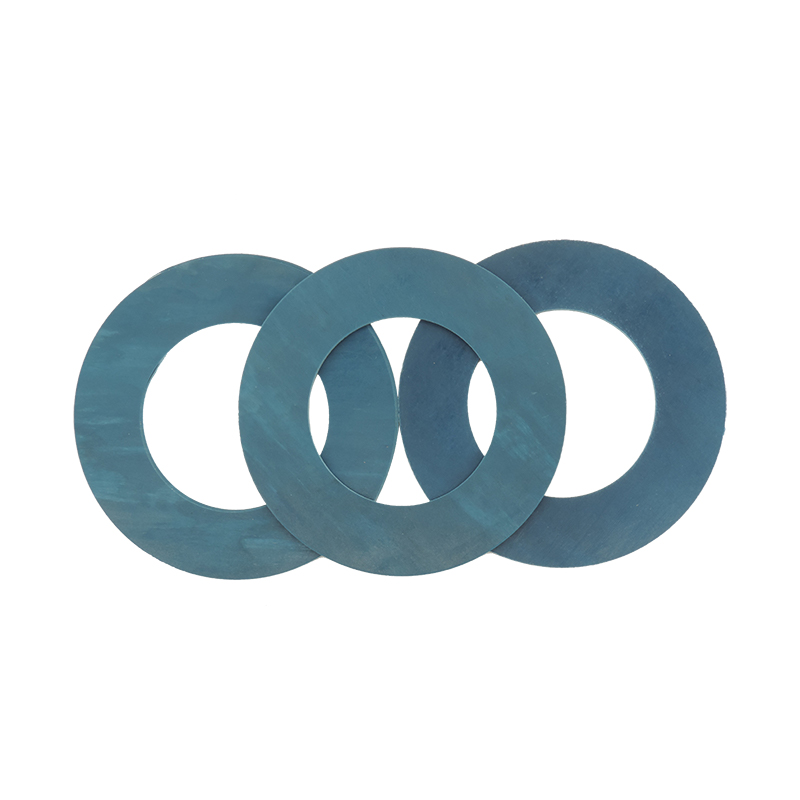

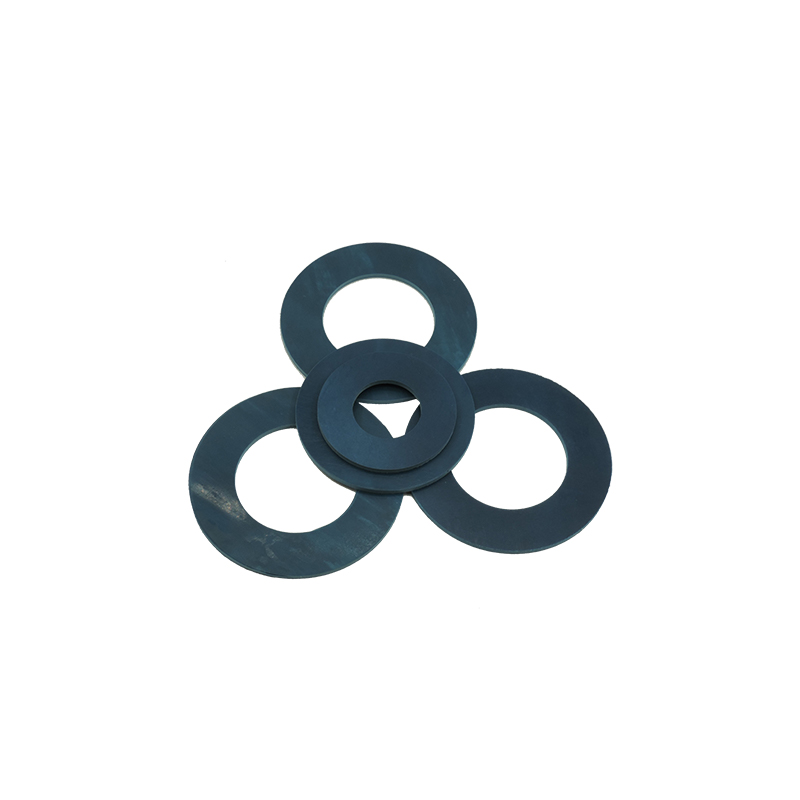

7900/7925/7950 Blue Compressed Aramid Fiber/Nitrile Binder Flange Gasket

JINTAI 7900/7925/7950

ASTM F104:f712120-A9B3E22K5L 151M5

Asbetteros-free compression gasket material

Use:

JINTAI 7900/7925/7950 is a general-purpose economical compression gasket material plate that can be used in weakly corrosive working conditions of pipelines, equipment and OEM equipment whose media are steam, hydrocarbons and refrigerants. This gasket material is an economical alternative material where the working conditions and uses are not severe:

7900/7925/7950 Blue Compressed Aramid Fiber/Nitrile Binder Flange Gasket

7900/7925/7950 Blue Compressed Aramid Fiber/Nitrile Binder Flange Gasket is a high-performance, economical non-asbestos gasket material suitable for flange sealing needs in a variety of industrial environments. Nitrile Binder Flange Gasket has high temperature resistance, excellent chemical resistance, high sealing performance and wide applicability.

Product Advantages

1. Excellent high temperature resistance

7900/7925/7950 Blue Compressed Aramid Fiber Gasket for high temperature can work stably in the range of -40°F to +450°F (-40°C to +232°C), suitable for steam, hot oil and high temperature fluid sealing.

2. Excellent chemical resistance

Nitrile Binder Aramid Fiber Flange Gasket chemical resistance enables it to resist oil, acid, alkali, solvents and a variety of industrial chemicals, extending its service life.

3. Industrial-grade strength and durability

Compressed Aramid Fiber Gasket 7900 series for industrial use adopts a high-density compression process to ensure high mechanical strength, suitable for high-pressure flange connections to prevent leakage.

4. Dedicated to the oil and gas industry

Blue Nitrile Binder Flange Gasket 7925 for oil and gas applications complies with API, ASME and other standards and is suitable for key sealing parts such as pipelines, valves, and pumps.

5. Low compression deformation, long-term reliable sealing

7950 Aramid Fiber/Nitrile Gasket low compression set can maintain its original shape even in long-term high-pressure environments, reducing maintenance frequency.

Why choose our products?

Longer service life – Aramid fiber reinforced structure, creep resistance, and reduced replacement frequency.

Higher safety – Low compression set ensures long-term sealing reliability.

Wider applicability – Suitable for high temperature, high pressure, and corrosive environments.

FAQ

Q1: Can this gasket be used in acidic media?

A: Yes, Nitrile Binder Aramid Fiber Flange Gasket chemical resistance makes it suitable for most acid and alkali environments.

Q2: What is the difference between 7900, 7925, and 7950 models?

A: The main difference is thickness and density, 7900 is suitable for low pressure, and 7950 is suitable for higher pressure environments.

Q3: Does it support customized sizes?

A: Yes, we provide non-standard size customization services to meet special flange requirements.

Specifications

Advantage:

1. Good sealing performance greatly reduces users’ production costs.

2. The multifunctional gasket has better properties than traditional economical gaskets.

3. Anti-stick properties reduce sealing surface cleaning time

4. Good compressibility and resilience ensure good sealing.

Element:

JINTAI 7900/7925/7950 contains high-strength aramid fiber, and its adhesive is high-quality nitrile rubber (NBR).

Anti-stick properties:

All JINTAl compression gasket materials have gone a long way in developing bonding agents with better anti-stick properties. All JINTAl compression gasket materials successfully pass the MIL-G-24696B 300°F/48 hrs Naval Facility Anti-Adhesion Test.

Typical performance:

|

|

Style 7900-off-white, marked Style 7925-green, marked Style 7950 - blue, marked |

|

Fiber chick |

Aramid |

|

Gluing material |

Nitrile rubber (NBR) |

|

Applicable fluid media |

Steam, water, inert gas, oil, fuel, dilute acid, dilute alkali |

|

Density |

1.7g/cm³(106 lbs/ft³) |

|

Tensile strength, ASTM F152 |

1700 psi (11.7 MPa) |

|

Compression rate, ASTM F36 |

7-17% |

|

Rebound rate, ASTM F36 |

40% |

|

Applicable temperature range |

-100-7°F(-73-371℃) |

|

Continuous operating temperature, max. |

500°F(260℃) |

|

Fluid PH value range (room temperature): |

3-11 |

|

pressure, max. |

1200psig(83 bar) |

|

Fluid penetration resistance ASTM F146 |

|

|

IRM 903 oil, 5h300°F/149℃ |

|

|

Thickness increases |

0-15% |

|

Weight gain |

15% |

|

ASTM Fuel B 5h/70° F/21℃ |

|

|

Thickness increases |

0-10% |

|

Weight gain |

12% |

|

Sealing |

|

|

ASTM F37(Fuel A) |

0.03mL/HR |

|

ASTM F37(Nitrogen) |

0.5mL/hr |

|

Insulation breakdown voltage, ASTMD 149 |

11.0KV/mm(279V/mil) |

|

DIN 3535Gas permeability |

0.05cc/min |

|

Creep relaxation rate ASTM F38 |

20% |

|

Flexible,ASTM F147 |

10x |

Note :

The performance of the ASTM standard is measured based on the base frame plate thickness of 1/16 inches, but ASTM F38 is measured based on the plate thickness of 1/32 inches. These properties can only be used as a general reference and cannot be used as a basis for risk or rejection. The data listed in this table are within the normal range of product performance. These data should not be used to compile technical specifications or used alone as a basis for design.

*When used for nominal pressure Class 300 or above, please consult our representative office.

KEEP IN TOUCH

-

Fugitive emissions in industrial aging flange systems present a dual challenge: environmental non-compliance and significant product loss. As flanges age, surface irregularities, warping, and pitting ...

READ MORE -

I. The Foundation of Reliable Sealing In high-stakes industrial environments—such as power generation, chemical processing, and shipping—the reliable containment of fluids is non-negotiable. Pure grap...

READ MORE -

I. Introduction: The Technical Parameters of Sealing In the highly demanding environments of modern industrial machinery—across the power generation, chemical processing, and shipping sectors—the func...

READ MORE

The Rise of Aramid Gaskets: Are They the Future of Industrial Sealing Solutions?

In the industrial field, sealing technology is a key link to ensure the safe and stable operation of equipment, and its importance is self-evident. With the continuous advancement of materials science, a high-performance fiber material called Aramid Fiber has gradually emerged in the field of sealing gaskets. Among them, the JINTAI 7900/7925/7950 series of aramid gaskets launched by Jiangsu Jintai Sealing Technology Co., Ltd. have become an ideal choice for solving sealing problems in many industries with their unique performance advantages.

Aramid, the full name of aromatic polyamide fiber, is a new type of synthetic fiber with excellent properties such as high strength, high modulus, high temperature resistance, and chemical corrosion resistance. These characteristics make aramid widely used in aerospace, military, automobile, chemical industry and other fields. In the field of sealing gaskets, aramid materials have become one of the important materials to replace traditional asbestos gaskets with their excellent corrosion resistance, good resilience and excellent thermal stability.

JINTAI 7900/7925/7950 series aramid gaskets, as the star product of Jiangsu Jintai Sealing Technology Co., Ltd., not only inherit all the advantages of aramid materials, but also further improve their sealing performance and durability through fine manufacturing processes.

Economical and efficient: As a general economical compression gasket material, JINTAI series aramid gaskets effectively control costs while ensuring excellent performance, providing users with a highly cost-effective solution. It performs particularly well in weakly corrosive conditions such as pipelines, equipment and OEM equipment for media such as steam, hydrocarbons and refrigerants.

Asbestos-free design: With the enhancement of environmental awareness, asbestos-free materials have become a development trend in the field of sealing gaskets. JINTAI series aramid gaskets completely abandon asbestos components, which not only meets environmental protection requirements, but also avoids health risks that may be caused by the release of asbestos fibers, providing a safer working environment for staff.

Excellent corrosion resistance: Aramid materials themselves have extremely strong chemical stability and can resist the erosion of various corrosive media such as acids, alkalis, and salts. This makes the JINTAI series aramid gaskets have a wide range of application prospects in the chemical, petroleum, natural gas and other industries, which can effectively extend the service life of equipment and reduce maintenance costs.

Good resilience and sealing: The high modulus characteristics of aramid fiber give the JINTAI series gaskets excellent resilience, and even under extreme conditions such as high temperature and high pressure, it can maintain stable sealing performance. This feature makes this series of gaskets perform well in preventing medium leakage and protecting equipment safety.

Wide range of application fields: With the above advantages, the JINTAI series aramid gaskets have been successfully used in many industries such as shipping, electricity, steel, chemical industry, machinery, etc. In these fields, it has won wide praise from users for its excellent sealing performance and reliable quality.

Strength and contribution of Jiangsu Jintai Sealing Technology Co., Ltd.

As a leading enterprise in China's customized sealing gaskets, sealing packings, and rubber products, Jiangsu Jintai Sealing Technology Co., Ltd. has always been committed to the research and development and innovation of sealing technology. The company has a professional R&D team and advanced production equipment, which can provide customers with a full range of solutions from design, manufacturing to after-sales service. Over the years, Jintai Sealing has established long-term and stable cooperative relationships with many industry giants, jointly promoting the progress and development of sealing technology.

With the continuous advancement of industrial technology and increasingly stringent environmental protection requirements, aramid gaskets, as the preferred solution for modern industrial sealing, will have a broader market prospect. Jiangsu Jintai Sealing Technology Co., Ltd., with its strong R&D strength, high-quality product quality and perfect service system, will continue to play a leading role in this field and make greater contributions to promoting the development of sealing technology in my country and even the world.

Eng

Eng  русский

русский