Technical Integrity: Installation, Re-Torquing, and Maintenance Protocols for Pure Graphite Gland Packing

2025.12.25

2025.12.25

Industry News

Industry News

- 1 I. The Foundation of Reliable Sealing

- 2 II. Installation Engineering: Critical Steps for PTFE Graphite Packing Installation Critical Steps

- 3 III. Operational Maintenance: Re-Torquing and Lifecycle Management

- 4 IV. Material Selection and Performance Trade-offs

- 5 V. Precision for Performance

- 6 VI. Frequently Asked Questions (FAQ)

- 6.1 1. Why must the packing rings be inserted with staggered joints?

- 6.2 2. When is the mandatory re-torquing cycle performed, and why is it necessary?

- 6.3 3. What is the technical function of the lantern ring and its Optimal lantern ring placement in valve packing?

- 6.4 4. When comparing Graphite packing vs carbon fiber packing comparison, which is better for extremely high-temperature steam service?

- 6.5 5. What measurement technique is recommended by Gland packing re-torquing procedure guidelines?

I. The Foundation of Reliable Sealing

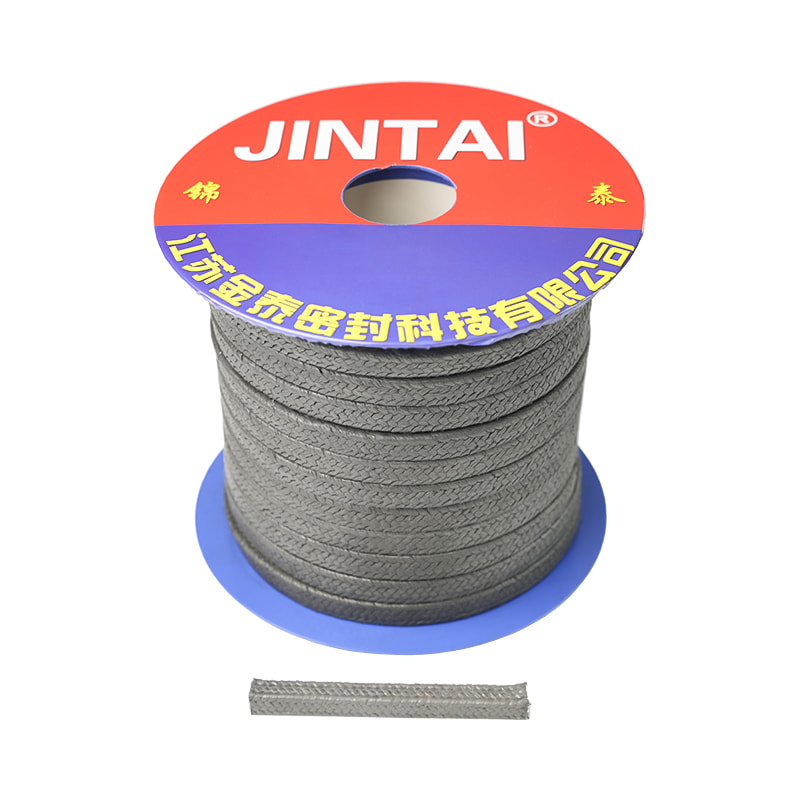

In high-stakes industrial environments—such as power generation, chemical processing, and shipping—the reliable containment of fluids is non-negotiable. Pure graphite gland packing, often enhanced with PTFE for superior chemical and low-friction properties, serves as a critical barrier in pumps, valves, and rotating equipment. Achieving zero-leakage performance and maximum service life hinges not merely on material quality but on strict adherence to installation and maintenance protocols.

Jiangsu Jintai Sealing Technology Co., Ltd., through its high-end sealing product brand, Nofstein, specializes in researching, manufacturing, and selling various types of seals and asbestos-free gaskets. Our commitment to technological innovation, advanced materials, and manufacturing processes enables us to provide high-quality sealing solutions that have been certified by organizations like the CCS classification society and the Chinese Academy of Coal Sciences. This expertise allows us to meet the exacting needs of industries worldwide.

II. Installation Engineering: Critical Steps for PTFE Graphite Packing Installation Critical Steps

The majority of packing failures are rooted in improper installation. Precision in the following procedures is non-negotiable.

A. Preparation and Cleaning Protocols

The stuffing box must be meticulously prepared. All old packing material must be removed, and the area inspected for corrosion, scoring, or burrs on the shaft/stem that could damage the new packing. The inner wall of the stuffing box must be concentric with the shaft. A key technical decision during the PTFE graphite packing installation critical steps is choosing the packing form. While cut coils are flexible, pre-formed rings offer superior density consistency and installation speed, leading to a more uniform seal and less cold flow consolidation after startup.

| Packing Material Form | Achievable Density Consistency | Installation Speed & Labor |

|---|---|---|

| Pre-formed Rings | High (Rings are pressed to specified density) | Fast (Minimized manual shaping) |

| Cut Coils (Field Cut) | Moderate (Highly dependent on installer skill) | Slow (Requires precise cutting and fitting) |

B. Ring Insertion and Orientation

Each ring of the pure graphite gland packing must be inserted individually using a split tamping tool, ensuring it is fully seated before the next ring is added. Joints must be staggered—ideally by 90° or 120°—to prevent a continuous leak path. Furthermore, the Optimal lantern ring placement in valve packing is critical; it must be positioned directly in front of the flush port to ensure that the lubricating or flush fluid is correctly directed into the packing set, cooling the stem and preventing abrasive media ingress.

III. Operational Maintenance: Re-Torquing and Lifecycle Management

Packing compression relaxes after initial operation (cold flow). Re-torquing is essential to maintain the correct seal stress.

A. The Gland Packing Re-Torquing Procedure Guidelines

The initial re-torquing cycle is crucial and should occur within 24 to 48 hours of operation, or after the first major temperature cycle. This step compensates for the "cold flow," or consolidation, of the packing material. The Gland packing re-torquing procedure guidelines strictly mandate the use of a torque wrench. Engineers should apply torque incrementally (e.g., 25% steps) in a star pattern and measure the reduction in gland follower movement, rather than simply counting the number of turns. The goal is to achieve a prescribed bolt stress or gland compression force that matches the packing material's optimal seating stress, minimizing friction and wear.

B. Long-Term Monitoring and PTFE Gland Packing Long-Term Maintenance Schedule

A preventative PTFE gland packing long-term maintenance schedule involves routine visual inspections and leak rate monitoring. While pure graphite gland packing exhibits superior heat dissipation and reduced friction compared to many synthetics, even these high-performance materials require monitoring. Inspections should look for excessive leakage (often measured in drops per minute, usually 1 to 5 drops/minute for pumps) or excessive gland follower travel, which indicates the need for minor adjustment, not complete replacement.

IV. Material Selection and Performance Trade-offs

Procurement must understand the technical characteristics that distinguish high-performance packing materials.

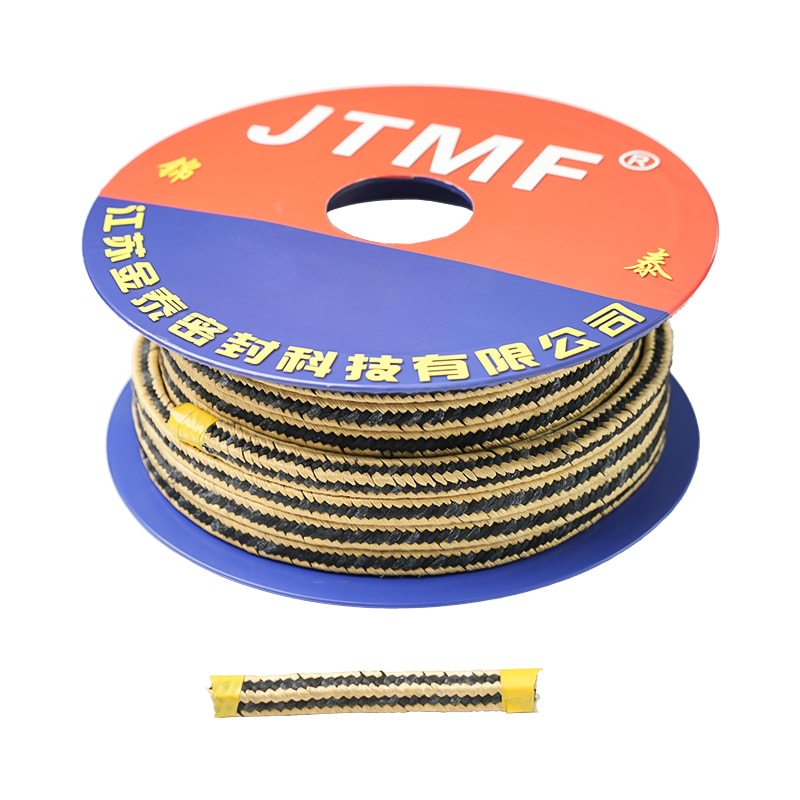

A. Graphite Packing vs Carbon Fiber Packing Comparison

Both materials are high-temperature solutions, but their properties differ significantly. Pure graphite gland packing (expanded graphite) excels in thermal conductivity, efficiently dissipating heat away from the shaft/stem interface, reducing friction wear. Conversely, carbon fiber packing offers superior tensile strength and abrasion resistance, making it suitable for abrasive media or high-velocity pumps, though it generally has a lower thermal conductivity and a higher friction factor than pure graphite.

| Sealing Material | Thermal Conductivity | Coefficient of Friction |

|---|---|---|

| Pure Graphite | High (Excellent heat dissipation) | Low (Ideal for reduced stem wear) |

| Carbon Fiber | Moderate | Moderate to High (Better abrasion resistance) |

B. Advanced Sealing Solutions

As a large comprehensive sealing technology enterprise, Nofstein continues to carry out technological innovation. We adopt advanced materials and manufacturing processes to develop hybrid materials that combine the chemical resistance of PTFE with the thermal resilience of graphite, ensuring the product adapts to challenging service conditions, such as superheated steam or aggressive chemical environments.

V. Precision for Performance

The operational success and safety of critical industrial equipment depend directly on the integrity of the sealing system. By strictly adhering to the PTFE graphite packing installation critical steps, precisely following the Gland packing re-torquing procedure guidelines, and maintaining a detailed PTFE gland packing long-term maintenance schedule, B2B clients can maximize the performance of their pure graphite gland packing. Jiangsu Jintai Sealing Technology Co., Ltd. is equipped with the rich experience and advanced products, enabling us to undertake various major projects globally.

VI. Frequently Asked Questions (FAQ)

1. Why must the packing rings be inserted with staggered joints?

- A: Staggering the joints (typically by 90° or 120°) prevents the formation of a continuous, helical leak path through the packing set. This is a fundamental PTFE graphite packing installation critical steps requirement to ensure uniform compression and effective sealing along the stem or shaft.

2. When is the mandatory re-torquing cycle performed, and why is it necessary?

- A: The mandatory re-torquing cycle is typically performed 24 to 48 hours after initial startup, or after the first major temperature cycle. It is necessary to compensate for the "cold flow" or material consolidation of the pure graphite gland packing under operational heat and pressure, preventing significant relaxation and subsequent leakage.

3. What is the technical function of the lantern ring and its Optimal lantern ring placement in valve packing?

- A: The lantern ring is a spacer ring placed within the packing set, typically aligned with the stuffing box's flush port. Its function is to introduce a fluid (lubricant or barrier fluid) to the stem, which cools the shaft and prevents abrasive particles from migrating into the packing set, extending the lifespan.

4. When comparing Graphite packing vs carbon fiber packing comparison, which is better for extremely high-temperature steam service?

- A: Both are high-temperature solutions, but pure graphite is generally preferred for extremely high-temperature steam due to its superior thermal conductivity. This property allows pure graphite gland packing to dissipate heat more efficiently than carbon fiber, reducing the temperature at the shaft interface and minimizing potential damage to the stem.

5. What measurement technique is recommended by Gland packing re-torquing procedure guidelines?

- A: Gland packing re-torquing procedure guidelines recommend using a calibrated torque wrench and following a star pattern to ensure uniform compression. Measuring the torque (bolt stress) is technically superior to simply counting bolt turns, as it ensures the required sealing stress is achieved consistently across all bolts.

Eng

Eng  русский

русский