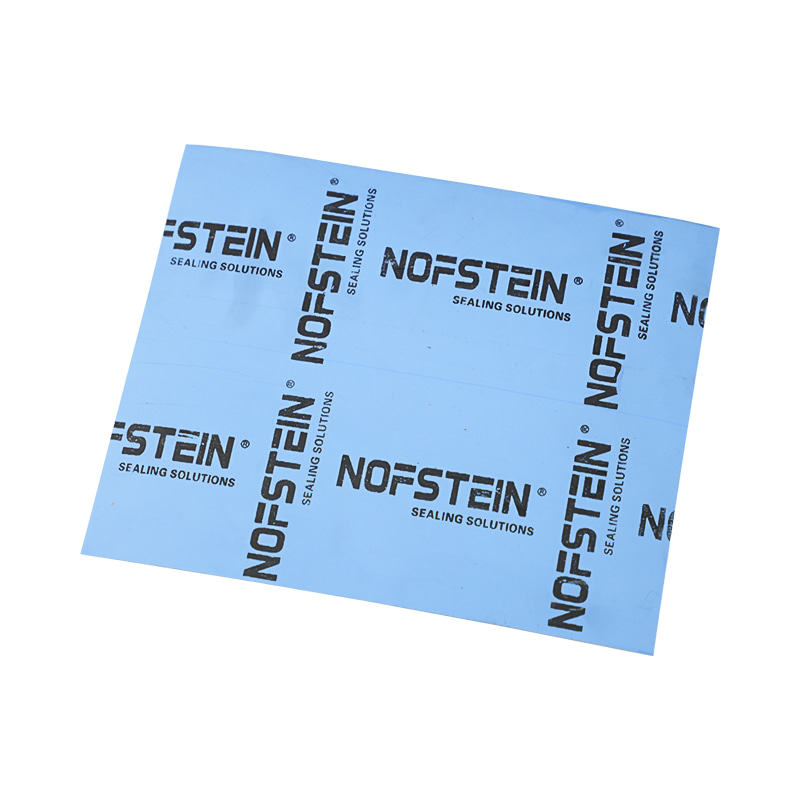

NOF-1000 High-Performance Non-Asbestos Gasket Material, Asbestos Free Jointing Sheet

High-performance gasket material for use in processes requiring neoprene (CR) as an adhesive, such as freezing processes.

This gasket material is veryly resistant to ozone, oils, non-aromatic solvents, and various refrigerants.

NOF-1000 High-Temperature Asbestos-Free Gasket Sheet - Durable Sealing Solution

NOF-1000 is a premium-grade non-asbestos gasket material designed for extreme temperature and pressure applications. This high-performance jointing sheet provides superior sealing performance while meeting strict asbestos-free regulations worldwide.

- 100% asbestos-free composition for safe handling and compliance with international regulations

- Exceptional heat resistance withstands temperatures up to 1000°F (538°C)

- Superior compression recovery maintains seal integrity under fluctuating pressures

- Chemical-resistant formulation compatible with oils, fuels, and most industrial fluids

- Easy to cut and install can be customized for any flange or joint configuration

The NOF-1000 asbestos-free gasket sheet is ideal for:

- Power generation equipment (turbines, boilers, heat exchangers)

- Oil and gas systems (pipeline flanges, refinery equipment)

- Chemical processing plants (pumps, valves, reactors)

- Marine applications (engine components, exhaust systems)

- Heavy machinery (hydraulic systems, compressors)

Why Choose NOF-1000 High-Temp Gasket Material?

Our non-asbestos jointing sheet outperforms traditional materials with:

- Longer service life - Resists degradation from heat cycling and chemical exposure

- Reduced maintenance - Maintains seal integrity longer than conventional gaskets

- Regulatory compliance - Meets OSHA, EPA, and international asbestos-free standards

- Versatility - Available in multiple thicknesses for various pressure requirements

- Cost efficiency - Lower total cost of ownership through extended replacement intervals

Custom Cutting Services

We offer precision gasket cutting services for NOF-1000 material to your exact specifications. Send us your drawings or templates for fast turnaround on custom-shaped gaskets.

Safety and Compliance Information

The NOF-1000 is fully compliant with:

- OSHA 29 CFR 1910.1001 (Asbestos standards)

- EPA Asbestos Hazard Emergency Response Act (AHERA)

- EU REACH Regulation (EC) No 1907/2006

- RoHS Directive 2011/65/EU

Specifications

|

|

Test method |

Specified Value |

Unit |

|

Max.Peak Temperature |

|

200 |

℃ |

|

Max.Operating Temperature |

|

150 |

C |

|

Max.Operating Pressure |

|

50 |

bar |

|

Density |

ASTM F 1315 |

1.60 -1.90 |

g/cm³ |

|

Compressibility |

ASTM F 36 J |

7-17.0 |

% |

|

Recovery |

ASTM F 36 J |

≥40.0 |

% |

|

Tensile Strength |

ASTM F 152 |

≥7.0 |

N/mm² |

|

ASTM oil no.3 (5h,150℃) |

ASTM F 146 |

|

|

|

Thickness Increase |

|

≤15.0 |

% |

|

Weight Increase |

|

≤20.0 |

% |

|

Fuel B(5h,23℃) |

ASTMF 146 |

|

|

|

Thickness Increase |

|

≤20.0 |

% |

|

Weight Increase |

|

≤20.0 |

% |

|

Water (5h,100℃) |

ASTMF 146 |

|

|

|

Thickness Increase |

|

≤10.0 |

% |

|

Weight Increase |

|

≤15.0 |

% |

|

Stress Relaxation (16hX175℃,2.00mm) |

DIN 52913 |

≥15.0 |

mpa |

KEEP IN TOUCH

-

I. Introduction: The Technical Parameters of Sealing In the highly demanding environments of modern industrial machinery—across the power generation, chemical processing, and shipping sectors—the func...

READ MORE -

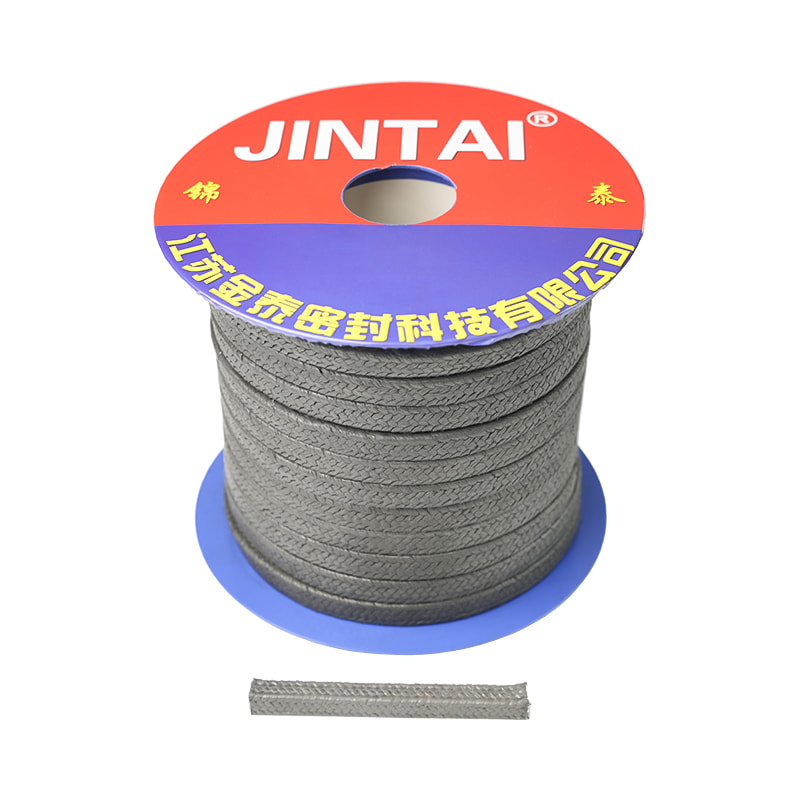

I. Sealing Solutions for Extreme Industrial Environments In critical industrial applications—spanning shipping, power generation, iron and steel, and chemistry—the integrity of dynamic seals is paramo...

READ MORE -

In critical industrial applications—from power generation to petrochemical processing—the performance of pure graphite gland packing is measured by its ability to reliably contain media across extreme...

READ MORE

NOF-1000 asbestos-free gasket: Isn't an environmentally friendly and efficient future a new chapter in industrial sealing?

With the rapid development of modern industry, sealing technology is becoming increasingly important as a key link to ensure the safe and stable operation of equipment. With the increasing awareness of environmental protection and increasingly stringent regulations, traditional asbestos-containing gaskets have gradually withdrawn from the stage of history due to their potential health risks and environmental problems, and have been replaced by a series of environmentally friendly and efficient new sealing materials. Among them, the NOF-1000 high-performance asbestos-free gasket material independently developed by Jiangsu Jintai Sealing Technology Co., Ltd. has become a leader in the industry with its excellent performance and wide application fields.

Jiangsu Jintai Sealing Technology Co., Ltd., as a leading enterprise in the field of domestic graphite composite gaskets, has always stood at the forefront of technological innovation, actively responded to the national green development strategy, and is committed to the research and development and promotion of asbestos-free sealing materials. NOF-1000 high-performance asbestos-free gasket material is the crystallization of this concept. It not only completely abandons traditional asbestos materials, adopts advanced fiber reinforcement technology and environmentally friendly adhesives, realizes pollution-free production from raw materials to finished products, but also achieves a comprehensive transcendence of traditional asbestos gaskets in performance, bringing revolutionary changes to the field of industrial sealing.

NOF-1000 high-performance asbestos-free gasket material has demonstrated excellent sealing performance with its unique formula design and exquisite production process. The material has excellent high temperature resistance, high pressure resistance, and corrosion resistance. It can maintain a stable sealing effect under extreme working conditions, effectively prevent medium leakage, and ensure equipment safety. At the same time, its good resilience and sealing adaptability enable NOF-1000 to easily cope with various complex and changeable sealing needs. It is widely used in multiple industries such as shipping, electricity, steel, chemical industry, machinery, etc., and has become a sealing solution trusted by many companies.

Jiangsu Jintai Sealing Technology Co., Ltd. is well aware that technological innovation is an inexhaustible driving force for the sustainable development of enterprises. The company continues to increase its R&D investment, introduce advanced technologies and equipment at home and abroad, and establish a high-quality R&D team, which provides a strong guarantee for the continuous optimization and upgrading of NOF-1000 high-performance asbestos-free gasket materials. Through continuous technological innovation, NOF-1000 has achieved significant improvements in material strength, sealing efficiency, service life, etc., further consolidating its leading position in the industry.

In addition to its excellent product performance, Jiangsu Jintai Sealing Technology Co., Ltd. has also won wide acclaim in the market with its high-quality services. The company always adheres to the "customer-centric" service concept, providing customers with all-round support from technical consultation, product selection, installation and commissioning to after-sales service. At the same time, the company also actively establishes close cooperative relations with upstream and downstream enterprises, jointly builds a mutually beneficial and win-win industrial ecology, and promotes the healthy development of the entire sealing industry.

Looking to the future, Jiangsu Jintai Sealing Technology Co., Ltd. will continue to uphold the corporate spirit of "innovation, environmental protection, high efficiency, and service", with NOF-1000 high-performance asbestos-free gasket material as the core, and continuously promote the innovation and development of sealing technology, and contribute more to the green transformation and high-quality development of the industrial field.

Eng

Eng  русский

русский