Graphite Gland Packing in High Temperature and High Pressure Applications

2025.08.21

2025.08.21

Industry News

Industry News

Introduction

Graphite Gland Packing is a critical sealing material used in industrial systems operating under extreme conditions. Its role is essential in maintaining leak-free operation in high-temperature and high-pressure environments, ensuring equipment longevity and operational safety.

Performance Characteristics of Graphite Gland Packing

Temperature and Pressure Resistance

- Maximum operating temperature: 450°C (842°F)

- Maximum operating pressure: 100+ bar

- Recommended for rotary equipment up to 20 m/s shaft speed

- Compression strength: 20–30 MPa depending on reinforcement

- Comparison with other packing materials:

| Material | Max Temperature | Max Pressure | Durability | Typical Applications |

| Graphite Gland Packing | 450°C | 100+ bar | High | Valves, pumps, heat exchangers |

| PTFE Packing | 260°C | 50 bar | Medium | Low temperature chemical lines |

| Metallic Packing | 600°C | 120 bar | High | High pressure steam and gas |

Chemical and Corrosion Resistance

- Resistant to acids, alkalis, and organic solvents

- Compatible pH range: 0–14

- Oxidation resistance up to 400°C in inert atmospheres

- Suitable for aggressive fluids in petrochemical, chemical, and power industries

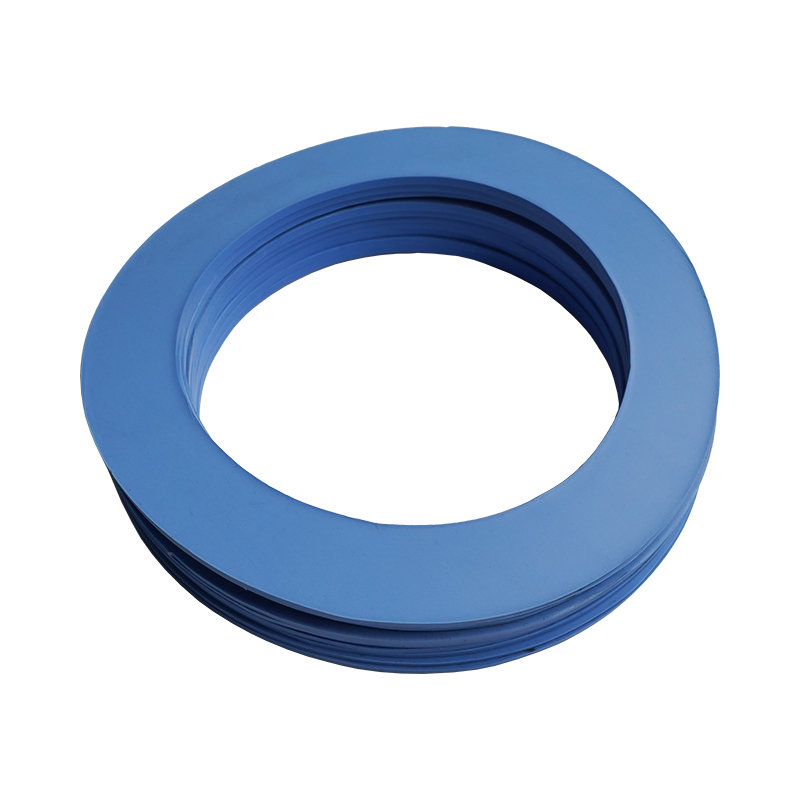

- Longevity improved with anti-extrusion rings in high-pressure applications

Choosing the Right Graphite Gland Packing

Selecting by Operating Conditions

- Choose high temperature graphite packing based on fluid type, temperature, and pressure

- Pressure rating guidelines:

- Low pressure: <50 bar

- Medium pressure: 50–100 bar

- High pressure: 100+ bar

- Rotation speed recommendations:

- Stationary valves: any speed

- Rotating pumps: ≤20 m/s

- Temperature classifications:

- Low: <200°C

- Medium: 200–350°C

- High: 350–450°C

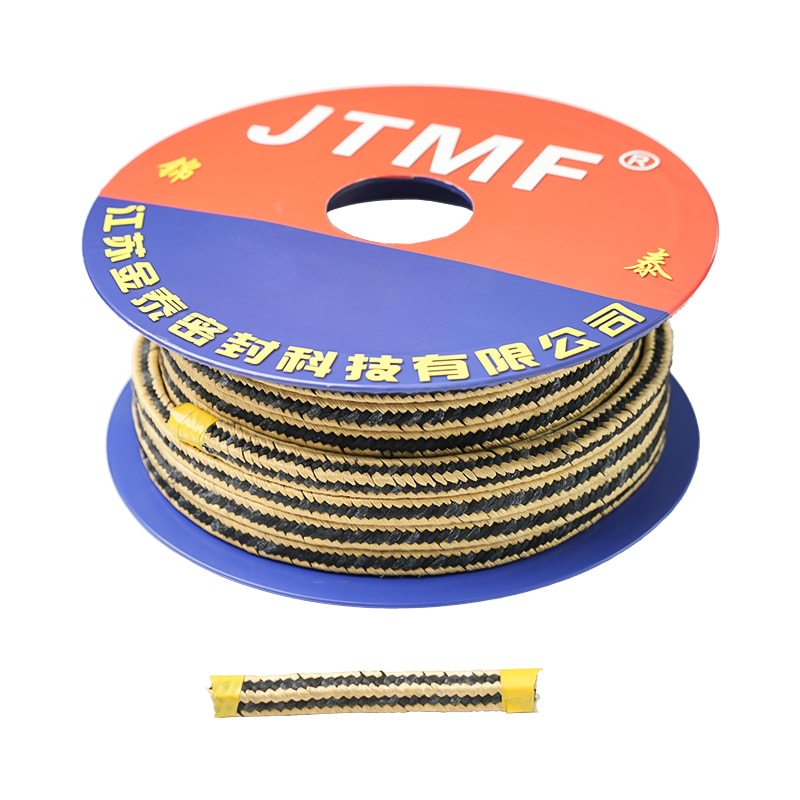

Material Types and Reinforcement

- Plain Graphite Gland Packing: flexible, suitable for moderate pressure

- Reinforced graphite packing for valves: includes metal wire or carbon fiber for high-pressure stability

- Expanded graphite provides superior chemical resistance and adaptability to irregular surfaces

- Graphite sealing solutions ensure leak-free performance in dynamic industrial systems

Installation and Maintenance

Installation Tips

- Proper compression: 10–15% of packing cross-section

- Ring alignment: staggered ends for continuous sealing

- Torque recommendations for gland bolts based on valve size and pressure

- Use anti-extrusion rings for pumps and high-pressure valves

Maintenance Best Practices

- Check packing compression every 2–4 weeks depending on temperature and pressure

- Replace packing when leakage exceeds 2–3 drops per minute for critical systems

- Follow graphite packing maintenance tips:

- Lubricate gland bolts to prevent seizure

- Monitor temperature excursions to avoid oxidation

- Inspect for fiber breakdown or extrusion

Industrial Applications

Key Industries

- Power generation: steam turbines, heat exchangers

- Chemical processing: reactors, pumps, agitators

- Petrochemical: valves, pipelines with corrosive media

Practical Use Cases

- Industrial graphite gland applications in high-temperature steam valves

- Rotary pumps handling acids and alkalis

- High-pressure chemical reactors needing reliable sealing

- Applications requiring periodic maintenance with minimal downtime

Conclusion

- Graphite Gland Packing offers excellent thermal, pressure, and chemical resistance

- Choosing the correct type, following installation procedures, and maintaining regularly ensures long-term reliability

- Using high temperature graphite packing and reinforced graphite packing for valves improves performance in demanding industrial applications

Frequently Asked Questions (FAQ)

1. What makes Graphite Gland Packing suitable for high-temperature and high-pressure applications?

- Graphite Gland Packing offers excellent thermal stability up to 450°C, can withstand pressures over 100 bar, and resists chemical corrosion. Its flexibility and durability make it ideal for industrial valves, pumps, and reactors.

- Jiangsu Jintai Sealing Technology Co., Ltd. has years of experience in developing high-performance sealing products like Graphite Gland Packing, ensuring reliability and long service life for demanding industrial applications.

2. How can I choose the right Graphite Gland Packing for my equipment?

- Consider operating temperature, pressure, shaft speed, and chemical environment. Use reinforced options for high-pressure valves or pumps.

- Jiangsu Jintai Sealing Technology Co., Ltd., through its high-end brand Nofstein, provides expert guidance on selecting Graphite Gland Packing and other sealing solutions tailored to specific industrial needs.

3. What maintenance practices ensure long-term performance of Graphite Gland Packing?

- Regularly monitor gland compression, check for leakage, and replace packing as necessary. Follow lubrication and inspection guidelines to prevent extrusion and wear.

- With decades of research and manufacturing experience, Jiangsu Jintai Sealing Technology Co., Ltd. offers comprehensive technical support and graphite packing maintenance tips to maximize product life and efficiency.

About Jiangsu Jintai Sealing Technology Co., Ltd.: Founded in 2004 and located on Xingyuan Road, Yuanzhu Industrial Park, in Taixing, Jiangsu Province, the company has sound quality management manuals and monitoring systems. Nofstein, its high-end sealing product brand, focuses on high-quality sealing solutions, advanced materials, and innovative designs. As a large comprehensive sealing technology enterprise, the company specializes in seals, environment-friendly asbestos-free gaskets, specialized rubber products, and parts insulation materials for pneumatic and hydraulic systems, serving industries including shipping, power, iron and steel, chemistry, and machinery.

Valves Pump Gland Packing Seals White Pure PTFE Gland Packing

Eng

Eng  русский

русский