A Comprehensive Guide to PTFE Graphite Gland Packing for Industrial Sealing

2025.08.14

2025.08.14

Industry News

Industry News

Gland Packing Materials and Types

In the field of industrial sealing, choosing the right packing material is crucial. Different materials possess unique properties to suit a variety of demanding working environments.

Overview of Common Packing Materials

- Aramid Packing: Features extremely high mechanical strength and abrasion resistance, often used in high-pressure, high-wear conditions such as with slurry and mortar pumps.

- Pure Graphite Packing: Made from woven expanded graphite, it has excellent resistance to high temperatures and high pressure, as well as self-lubricating properties. It is widely used in high-temperature steam valves and pipelines.

- Pure PTFE Packing: Offers outstanding chemical resistance, capable of withstanding the corrosion of almost all chemical media. It also has a very low coefficient of friction. It is commonly used in the food, pharmaceutical, and chemical industries.

- Carbon Fiber Packing: High strength and wear resistance, with good thermal conductivity and chemical resistance. It is suitable for high-speed rotating equipment and high-temperature media.

Focus on PTFE Graphite Gland Packing

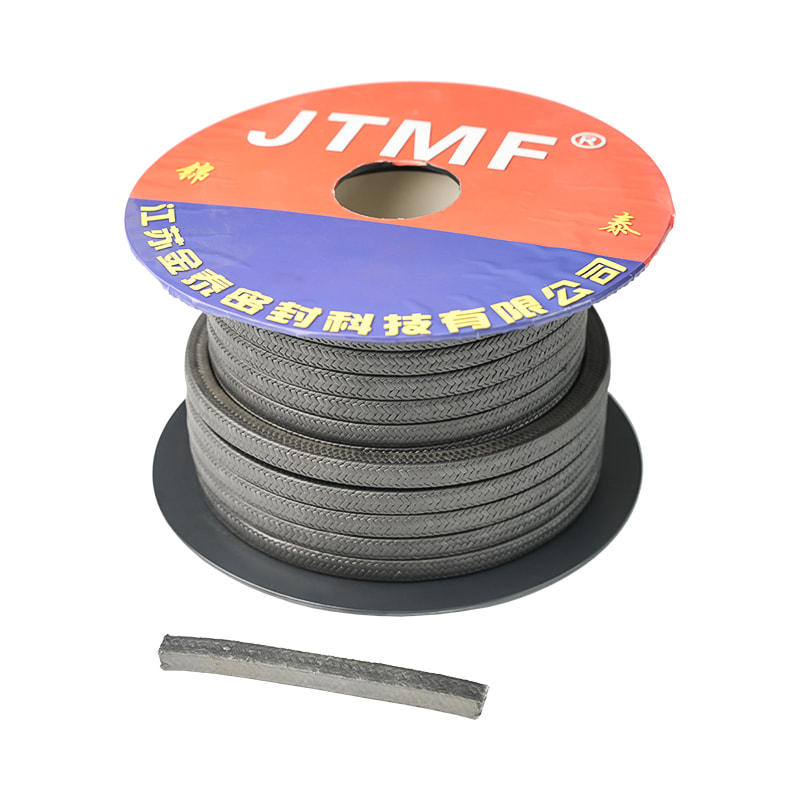

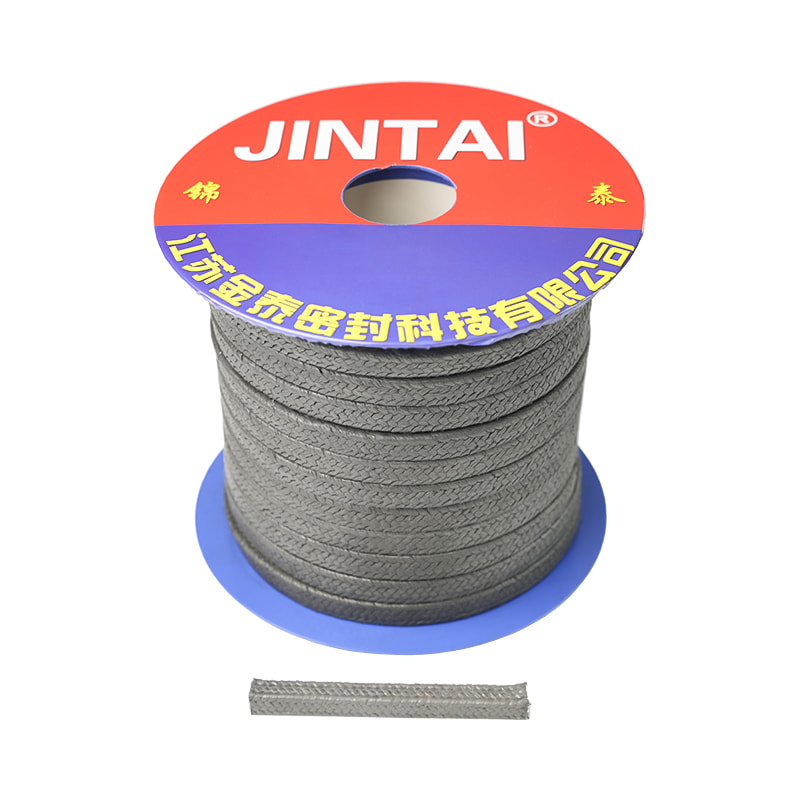

PTFE graphite gland packing is a composite packing that combines the advantages of both polytetrafluoroethylene (PTFE) and graphite. It is typically made by braiding PTFE yarns containing graphite, or by impregnating PTFE packing with graphite. This combination creates a complementary set of performance features.

- PTFE Advantages: Provides excellent chemical inertness, allowing it to work in almost all pH ranges. It also has a very low coefficient of friction, which reduces shaft wear and extends packing life.

- Graphite Advantages: Gives the packing superior thermal conductivity, which rapidly dissipates heat generated by friction. This prevents the packing from overheating and enhances its stability in high-pressure, high-speed conditions.

Parameter Comparison of PTFE and Graphite Packing

To better understand the benefits of PTFE graphite gland packing, here is a comparison of the performance parameters of pure PTFE and pure graphite packing:

| Feature | Pure PTFE Packing | Pure Graphite Packing |

| Color | White | Black |

| Chemical Resistance | Excellent (except molten alkali metals) | Excellent (except strong oxidizing agents) |

| Temperature Range | Approx. -100°C to 260°C | Approx. -200°C to 650°C |

| Thermal Conductivity | Poor (a poor conductor of heat) | Excellent (can effectively dissipate heat) |

| Coefficient of Friction | Very low | Low (has self-lubricating properties) |

| Application Limitations | Poor thermal conductivity; prone to overheating in high-speed operation | Can oxidize; not suitable for strong oxidizing media |

PTFE graphite gland packing combines the best of both materials: the chemical inertness and low friction of PTFE, with the excellent thermal conductivity and high-temperature resistance of graphite. This makes it an extremely versatile, well-balanced sealing solution, particularly for applications that require both corrosion resistance and heat dissipation.

Gland Packing: A Comprehensive Guide to Industrial Sealing Solutions

Choosing the correct gland packing is essential for the efficient and safe operation of industrial equipment. This process requires a comprehensive evaluation of several factors to ensure the selected packing can withstand the specific working conditions.

How to Select the Right Packing

To choose the appropriate packing for a specific application, you must analyze several core parameters:

- Temperature: The packing must be able to withstand the maximum temperature of the medium. If the temperature is too high, the packing material can soften, decompose, or harden, leading to a loss of sealing performance.

- Pressure: The packing needs to withstand system pressure without being squeezed out or deformed. Excessive pressure can cause the packing to extrude from the stuffing box, resulting in leakage.

- Medium: The packing must resist corrosion or erosion from the fluid it contacts (e.g., water, steam, chemicals, oil). The chemical properties of the medium directly determine the choice of packing material.

- Shaft or Stem Speed: For rotating or reciprocating equipment, the speed of the shaft or stem affects the heat generated by friction. High-speed operation requires packing with better thermal conductivity to prevent overheating.

- Equipment Type: Different types of equipment—such as pumps, valves, and mixers—have different performance requirements for packing. For example, pumps typically require good heat dissipation, while valves prioritize the reliability of a static seal.

Broad Applications of PTFE Graphite Gland Packing

PTFE graphite gland packing is a highly versatile and well-balanced choice due to its unique composite performance. It combines the chemical resistance of PTFE with the excellent thermal conductivity of graphite, allowing it to handle a wide range of demanding operating conditions.

Here are some typical applications where PTFE graphite gland packing is suitable:

- Pumps: It is effective in centrifugal and reciprocating pumps that handle corrosive chemicals, water, hot water, or steam, as it can dissipate heat and resist media corrosion.

- Valves: It is suitable for various industrial valves in the chemical, oil, and natural gas industries, providing a reliable seal. Its low-friction properties also reduce the operating force required for frequently used valves.

- Mixers and Agitators: It can effectively seal the shafts in equipment like chemical reactors, preventing media leakage and withstanding the motion and friction from agitation.

Performance Comparison of Different Packing Materials

The table below compares the suitability of PTFE graphite gland packing with several other common types of packing in different working conditions to help you make a better choice:

| Feature | PTFE Graphite Packing | Aramid Packing | Pure Graphite Packing | Pure PTFE Packing |

| Temperature Resistance | Good | Fairly good | Excellent | Good |

| Pressure Resistance | Good | Excellent | Excellent | Fairly poor |

| Chemical Resistance | Excellent | Good | Good (not for strong oxidizers) | Excellent |

| Coefficient of Friction | Low | High | Low | Very low |

| Thermal Conductivity | Excellent | Poor | Excellent | Poor |

| Abrasion Resistance | Good | Excellent | Poor | Poor |

| Typical Applications | Pumps and valves for corrosive media | High-wear, high-pressure pumps | High-temp, high-pressure steam valves | Food, pharmaceutical, and strong acid/alkali environments |

Installation and Maintenance of PTFE Graphite Gland Packing

For PTFE graphite gland packing to deliver its best sealing performance and long service life, correct installation and regular maintenance are critical. Improper installation is a leading cause of seal failure and equipment damage.

Proper Installation Techniques

- Clean the Stuffing Box: Before installing new packing, you must thoroughly clean the stuffing box of all old packing residue and debris. Inspect the shaft or stuffing box for any signs of wear or scratches.

- Measure and Cut: Based on the dimensions of the stuffing box, cut the PTFE graphite gland packing into rings. The cuts should be clean and can be made at an angle or straight. Ensure each ring is cut to the precise length to fit snugly inside the stuffing box.

- Install Ring by Ring: The packing should be installed one ring at a time, not all at once. Each ring should be inserted along the shaft and gently pressed into place using a specialized tool or a block of wood to ensure it is properly seated.

- Stagger the Cuts: The cuts of each packing ring should be staggered by 90° or 180° from the cuts of the previous ring to prevent the creation of a direct leakage path.

- Pre-tighten and Run-in: After all the packing is installed, tighten the gland nuts evenly, but not too tightly. Run the equipment without a load for a period, checking for a slight amount of leakage. If the leakage is excessive, gradually and evenly tighten the nuts until the leakage rate is within an acceptable range.

Common Installation Errors and How to Avoid Them

| Common Error | Result | How to Avoid |

| Inaccurate cutting | Gaps between packing rings, causing leakage | Use a professional tool for precise measurement and cutting, ensuring clean cuts |

| Not staggering cuts | Creates a leakage path and poor sealing performance | Strictly follow the procedure of staggering the cuts of each ring by at least 90 degrees |

| Inserting all at once | Uneven pressure on the packing, creating internal voids | Install and compress the packing ring by ring to ensure each one is tightly seated |

| Overtightening | Packing hardens from excessive compression, increasing friction and wear, potentially damaging the shaft | Follow the principle of step-by-step tightening, adjusting based on the observed leakage rate |

Routine Maintenance Tips

- Regular Inspections: Periodically check the stuffing box for leakage. A small amount of leakage is normal and necessary for the packing’s self-lubrication. If the leakage increases, tighten the gland nuts appropriately.

- Supplemental Lubrication: PTFE graphite gland packing has self-lubricating properties, but in some high-temperature or high-speed conditions, supplemental external lubrication can enhance its performance.

- Timely Replacement: If the packing is worn to the point where leakage cannot be controlled by adjusting the gland nuts, or if the packing appears hardened or carbonized, it should be replaced immediately with new packing.

- Spare Parts Management: Keep spare packing in a clean, dry, and ventilated environment. Avoid crushing or deforming it so it is ready when needed.

Troubleshooting PTFE Graphite Gland Packing

In industrial applications, even high-quality PTFE graphite gland packing can fail for a variety of reasons. Timely identification and resolution of these issues are crucial for maintaining equipment performance and avoiding downtime.

Identifying Problems

- Excessive Leakage: While a slight amount of leakage is normal, a significant increase could be a sign of worn-out packing, a loose gland, or improper installation.

- Equipment Overheating: Over-tightening can cause the packing and the shaft to heat up. This may indicate that the packing is installed too tightly or that there is insufficient lubrication.

- Shaft or Stuffing Box Wear: Problems with the packing material or installation can cause wear on the shaft or stuffing box surface, which will affect the seal and shorten the packing’s lifespan.

Solutions

Here are the steps for troubleshooting and resolving the issues mentioned above:

| Problem | Possible Cause | Solution |

| High Leakage | Loose gland nuts; worn packing; improper installation | Uniformly tighten the gland nuts; replace with new packing; reinstall the packing correctly |

| Equipment Overheating | Over-tightened packing; insufficient lubrication; misaligned shaft | Slightly loosen the gland nuts; check or add lubrication; inspect equipment alignment |

| Shaft Wear | Packing has a high coefficient of friction; packing contains hard particles; poor lubrication | Use a better-lubricated packing (such as PTFE graphite gland packing); check the packing quality; ensure adequate lubrication |

Jiangsu Jintai Sealing Technology Co., Ltd., through its high-end sealing brand Nofstein, once encountered a challenge with a chemical plant’s pump. The pump handled corrosive media at a high rotational speed, and the original pure PTFE packing frequently overheated due to its poor thermal conductivity. This led to packing hardening and subsequent leakage.

The Nofstein team analyzed the situation and recommended using PTFE graphite gland packing. This packing combines the excellent corrosion resistance of PTFE with the superior thermal conductivity of graphite. After installation, the graphite component effectively dissipated the heat generated by friction, solving the overheating problem. Simultaneously, the low-friction properties of the PTFE reduced shaft wear and extended the life of both the packing and the equipment. This significantly lowered maintenance costs and downtime.

This case study clearly demonstrates that choosing and using a high-performance packing like PTFE graphite gland packing is key to solving complex industrial sealing challenges. By leveraging years of accumulated scientific experiments and manufacturing expertise, along with a robust quality management system, Jiangsu Jintai Sealing Technology Co., Ltd. provides high-quality and reliable sealing solutions for various industries.

Eng

Eng  русский

русский