How to Choose the Right Grade of Carbon Gland Packing for Corrosive Chemical Sealing

2026.02.19

2026.02.19

Industry News

Industry News

- 1 Understanding Material Compositions: Carbon vs. Graphite

- 2 Chemical Compatibility and pH Resistance

- 3 Temperature and Pressure Limits for Industrial Applications

- 4 The Role of Impregnation: PTFE vs. Graphite Finishes

- 5 Conclusion: Selecting the Optimal Grade

- 6 Frequently Asked Questions (FAQ)

- 6.1 1. Is carbon gland packing suitable for potable water applications?

- 6.2 2. How to install carbon gland packing to prevent shaft scoring?

- 6.3 3. What is the difference between carbon and graphite gland packing in terms of cost-effectiveness?

- 6.4 4. Does Nofstein carbon packing require external lubrication?

- 6.5 5. Can I use high temperature carbon packing for valves in steam service?

- 7 Industry References

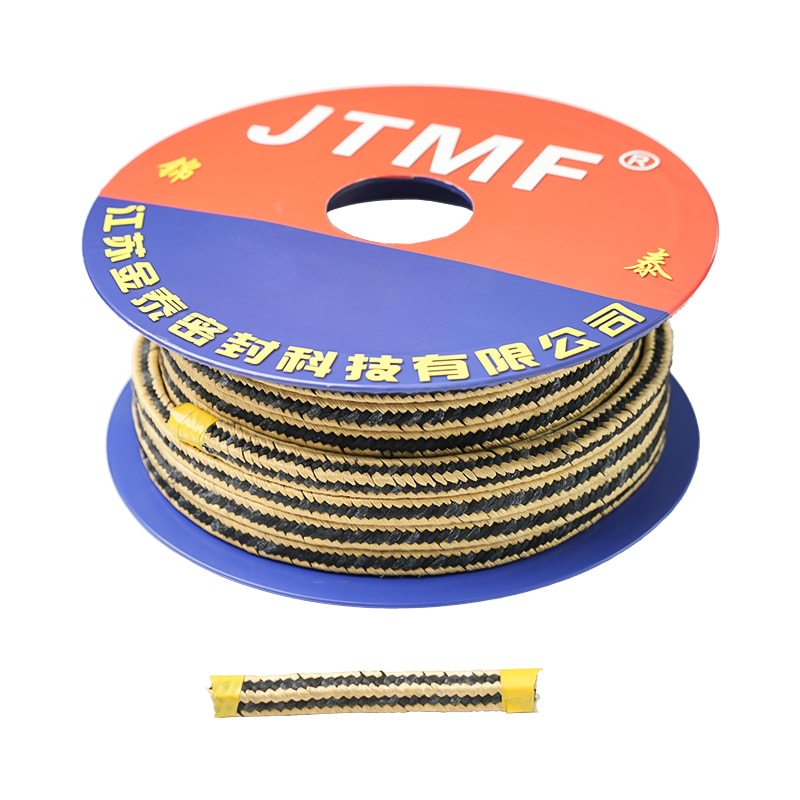

In the demanding landscape of industrial fluid handling, the integrity of a sealing system can dictate the operational lifespan of expensive machinery. Selecting the appropriate carbon gland packing is a critical engineering decision, particularly when dealing with aggressive, corrosive chemicals that can degrade standard sealing materials. Jiangsu Jintai Sealing Technology Co., Ltd., founded in 2004, has spent decades perfecting high-end sealing solutions under our premier brand, Nofstein. Our products, backed by CCS classification society identification and rigorous testing from the Chinese Academy of Coal Sciences, are designed to meet the high-specification needs of the shipping, power, and chemical industries.

Understanding Material Compositions: Carbon vs. Graphite

The first step in selecting a seal is understanding the molecular differences between high-purity carbon and graphite fibers. While often used interchangeably in casual conversation, the difference between carbon and graphite gland packing is significant in terms of stiffness and thermal conductivity. Carbon fiber packing is generally stronger and more resistant to abrasion in slurries, whereas graphite offers superior self-lubrication and heat dissipation. Choosing the wrong grade can lead to shaft scoring or premature packing failure under high-velocity chemical flow.

Comparison of Physical Properties

Carbon fiber excels in high-pressure mechanical strength, while graphite-reinforced grades prioritize thermal management and low friction coefficients.

| Property | High-Purity Carbon Gland Packing | Flexible Graphite Packing |

| Mechanical Strength | Excellent (Resistant to extrusion) | Moderate (Requires end rings) |

| Thermal Conductivity | Moderate | High (Excellent heat dissipation) |

| Chemical pH Range | 0–14 (Except strong oxidizers) | 0–14 (Except strong oxidizers) |

| Friction Coefficient | Low | Ultra-Low (Self-lubricating) |

Chemical Compatibility and pH Resistance

When sealing corrosive media, the pH level and the oxidizing nature of the fluid are paramount. A common engineering challenge is finding a chemical resistant pump packing that does not leach impurities into the process. High-grade carbon gland packing is virtually inert across the entire pH scale (0–14). However, engineers must be cautious with strong oxidizing agents like nitric acid or concentrated sulfuric acid, which can cause the carbon structure to oxidize at elevated temperatures. Nofstein high-end grades often incorporate specialized inhibitors to mitigate this risk.

Assessing Corrosion Inhibitors

Standard packing might lead to galvanic corrosion on stainless steel shafts. In contrast, premium grades treated with passive corrosion inhibitors provide a sacrificial protective layer, significantly extending the life of the pump sleeve.

| Seal Type | Galvanic Corrosion Risk | Protection Mechanism |

| Standard Carbon Packing | Moderate to High | None |

| Nofstein Premium Grade | Low | Passive Corrosion Inhibitor Coating |

Temperature and Pressure Limits for Industrial Applications

High-temperature corrosive environments require a high temperature carbon packing for valves that maintains its dimensional stability. Standard carbon fibers can withstand temperatures up to 450°C in oxidizing atmospheres and over 2000°C in non-oxidizing or inert environments. When combined with advanced braiding techniques—such as the square cross-braid utilized at our Taixing industrial park—the carbon gland packing can handle extreme pressures without sacrificing flexibility.

Key Technical Indicators:

- Pressure Limits: Capable of handling up to 300 bar in valve applications when used with proper end rings.

- Shaft Speed: Supports peripheral speeds up to 20 m/s in centrifugal pumps due to low thermal expansion.

- Thermal Stability: Minimal volume loss at peak operating temperatures compared to PTFE-based seals.

The Role of Impregnation: PTFE vs. Graphite Finishes

To achieve a leak-free seal, the "voids" between the braided fibers must be filled. For those asking how to install carbon gland packing in chemical pumps, the type of impregnation significantly affects the "break-in" period. PTFE impregnation provides excellent chemical resistance and a tight seal at low temperatures, while graphite impregnation is superior for high-velocity, high-temperature applications where heat dissipation is the primary concern.

Impregnation Comparison

PTFE-impregnated carbon provides a cleaner, more fluid-tight seal, while graphite-impregnated versions allow for higher shaft speeds with less frictional heat build-up.

| Feature | PTFE Impregnated Carbon | Graphite Impregnated Carbon |

| Max Temperature | Up to 280°C (PTFE limit) | Up to 450°C+ |

| Seal Tightness | Superior for gases/thin liquids | Moderate (Better for high speed) |

| Chemical Range | Full pH range (Standard) | Full pH range (High Heat) |

Conclusion: Selecting the Optimal Grade

Choosing the right carbon gland packing requires a balance of mechanical strength, chemical compatibility, and thermal resilience. By evaluating the carbon fiber packing vs ptfe packing trade-offs—where carbon provides higher strength and heat resistance at the cost of some flexibility—engineers can specify a solution that minimizes downtime. Jiangsu Jintai Sealing Technology Co., Ltd. remains committed to providing these high-standard, environmentally friendly products to the global market, ensuring that every Nofstein seal provides the reliability your major projects demand.

Frequently Asked Questions (FAQ)

1. Is carbon gland packing suitable for potable water applications?

While carbon is chemically inert, it is generally recommended for industrial use. For food or potable water, we suggest our asbestos-free environment-friendly gaskets or specialized rubber products that meet specific food-grade certifications.

2. How to install carbon gland packing to prevent shaft scoring?

Ensure the shaft is smooth and free of burrs. Cut the rings at a 45-degree angle (scarf cut) and stagger the joints by 90 degrees. Importantly, do not over-tighten the gland nut initially; allow for a steady leak-off during the first hour of operation to facilitate cooling and lubrication.

3. What is the difference between carbon and graphite gland packing in terms of cost-effectiveness?

Carbon fiber packing is typically more expensive due to the manufacturing process of the fiber, but it offers longer service life in abrasive or high-pressure chemical environments, leading to a lower Total Cost of Ownership (TCO).

4. Does Nofstein carbon packing require external lubrication?

Our high-purity carbon fibers are often self-lubricating, but in high-speed pump applications, an external flush (lantern ring) is recommended to manage heat and prevent the accumulation of corrosive salts within the stuffing box.

5. Can I use high temperature carbon packing for valves in steam service?

Yes, carbon packing is an excellent choice for superheated steam. It maintains its structural integrity far better than polymer-based seals and does not harden over time, ensuring the valve remains operable after long periods of inactivity.

Industry References

- FSA (Fluid Sealing Association) - Gland Packing Handbook.

- ASTM F36: Standard Test Method for Compressibility and Recovery of Gasket Materials.

- CCS Classification Society Quality System Standards.

- ESA (European Sealing Association) Best Plant Role for Gland Packing.

Eng

Eng  русский

русский