Gland Packing: A Comprehensive Guide to Industrial Sealing Solutions

2025.08.07

2025.08.07

Industry News

Industry News

This guide provides a detailed overview of gland packing, focusing on the core material PTFE graphite gland packing and its applications. It also covers various other packing materials, their specific uses, and best practices for selection and installation, with a special emphasis on pump sealing applications.

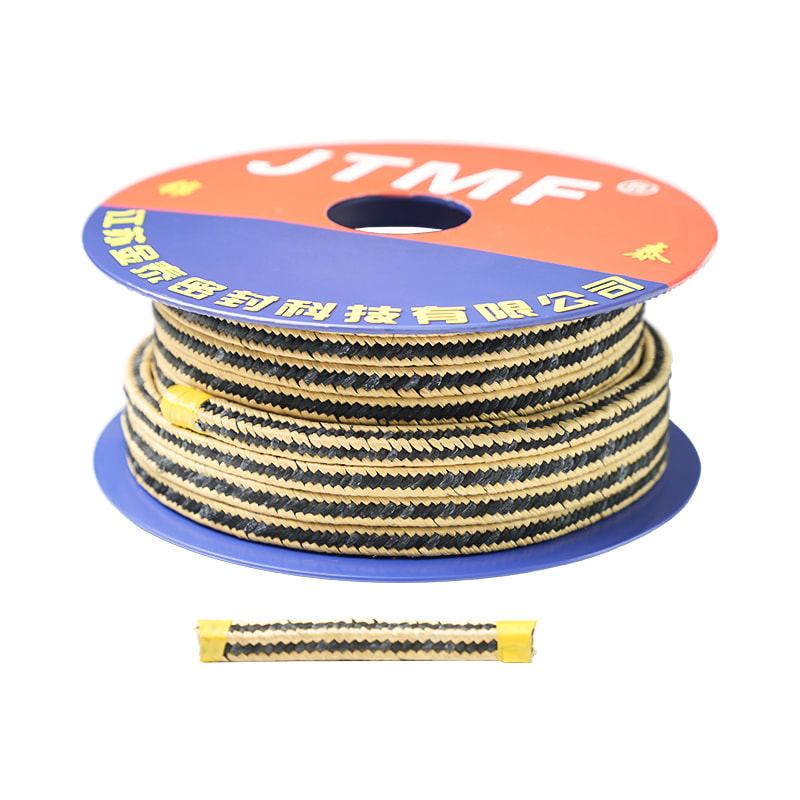

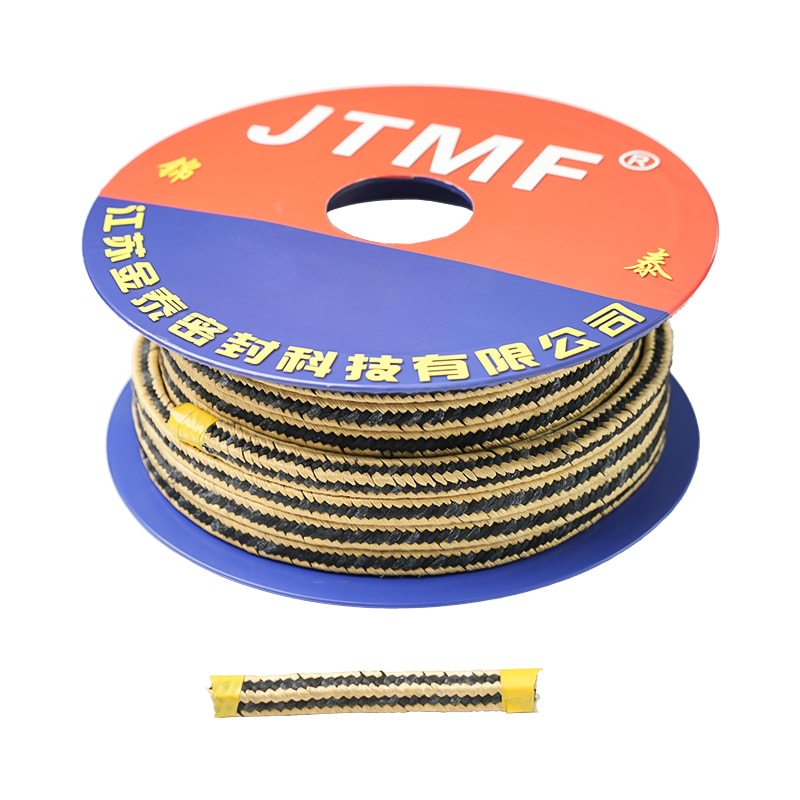

Cord Graphite Aramid Fiber Zebra Braided Gland Packing With Oil

I. The Role of Gland Packing in Industrial Sealing

Gland packing is a critical sealing component used to prevent leaks of fluids or gases from dynamic parts of pumps, valves, and other rotating machinery. Among the many materials available, PTFE graphite gland packing is a top choice due to the synergistic advantages of its two key components:

PTFE (Polytetrafluoroethylene)

Known for its exceptional chemical inertness, PTFE resists corrosion from almost all chemical media, making it stable in harsh environments like strong acids and alkalis. Its excellent self-lubricating properties also significantly reduce friction, extending the life of both the packing and the shaft.

Graphite

Graphite provides outstanding high-temperature resistance and thermal conductivity. It quickly dissipates heat generated by friction, preventing the packing from overheating. Graphite's flexibility also allows it to conform to the stuffing box, ensuring a tighter seal.

Parameter Comparison: PTFE Graphite vs. Other Common Packings

| Property | PTFE Graphite Packing | Pure PTFE Packing | Pure Graphite Packing | Aramid Fiber Packing |

|---|---|---|---|---|

| Working Temp. | -100℃ to 280℃ | -100℃ to 250℃ | -200℃ to 650℃ | -100℃ to 280℃ |

| Chemical Resist. | Excellent | Excellent | Good (except strong oxidizers) | Good (not strong acids/alkalis) |

| Friction Coeff. | Low | Very low | Low | High |

| Wear Resist. | Good | Fair | Fairly good | Excellent |

| Thermal Cond. | Excellent | Poor | Excellent | Poor |

II. In-Depth Analysis of Gland Packing Materials and Applications

Beyond the classic PTFE graphite, other packing materials are optimized for specific conditions and media.

Expanded PTFE Gland Packing

Made from pure, flexible PTFE fibers, this packing is exceptionally soft and chemically inert. It's ideal for use in the food, pharmaceutical, and chemical industries where contamination and corrosion are major concerns.

Graphite Packing Rope

Known for its extreme temperature and pressure resistance, this packing is a go-to for high-temperature valve and boiler applications in power plants and petrochemical facilities. Its high thermal conductivity is crucial for dissipating heat in these demanding environments.

PTFE Carbon Fiber Packing

By combining the strength of carbon fiber with the lubrication of PTFE, this packing offers high durability and wear resistance. It's well-suited for media containing abrasive particles, making it popular in the paper and pulp or mining industries.

Aramid Fiber Gland Packing

This material stands out for its high tensile strength and superior wear resistance. It's the top choice for abrasive media like slurries and sewage, commonly found in metallurgical and mining applications.

Performance Comparison of Different Packing Materials

| Property | PTFE Graphite | Expanded PTFE | Graphite Rope | PTFE Carbon Fiber | Aramid Fiber |

|---|---|---|---|---|---|

| Main Advantage | Balanced performance | Chemical inertness | High temp. & pressure | High strength & wear resist. | Extreme wear resist. |

| Temp. Range | -100℃ to 280℃ | -100℃ to 250℃ | -200℃ to 650℃ | -100℃ to 280℃ | -100℃ to 280℃ |

| Wear Resist. | Good | Poor | Fairly good | Excellent | Superior |

| Typical Use | General corrosive media | Food-grade, high-purity | High temp. steam | Abrasive media | Slurries, abrasive particles |

III. Gland Packing in Pump Applications: Pump Gland Packing

Properly selected gland packing is vital for a pump's efficiency and lifespan. It prevents fluid leakage, protects bearings, and ensures operational safety.

Centrifugal Pumps

These pumps typically have high rotational speeds. PTFE graphite and PTFE carbon fiber packing are excellent choices due to their low friction and high thermal conductivity, which minimize shaft wear and overheating.

Plunger Pumps

Operating at high pressure, these pumps require packing with high compressive strength and anti-extrusion capabilities. Aramid fiber packing or reinforced packing with aramid corners is recommended to handle the pressure.

Slurry Pumps

Used for media with abrasive solids, slurry pumps demand highly wear-resistant packing. Aramid fiber packing is the ideal solution, as its high tensile strength and wear resistance effectively resist abrasion from solid particles.

IV. Correct Selection and Installation of Gland Packing

The performance of gland packing depends on both proper selection and meticulous installation.

Selection Guide

The choice of packing should be based on the medium (corrosive or abrasive), operating conditions (temperature, pressure), equipment type (pump or valve), and shaft speed.

Installation Techniques

- Preparation: Thoroughly clean the stuffing box and shaft.

- Cutting: Cut packing rings at a precise 45° angle.

- Installation: Install rings one by one, staggering the cuts at 90° or 180° to prevent leak paths.

- Tightening: Use gland bolts to apply pressure evenly, but avoid over-tightening.

- Adjustment: After startup, monitor leakage. Adjust the gland nuts slightly to maintain a minimal, controlled leak for lubrication and cooling.

As a leading sealing technology enterprise, Jiangsu Jintai Sealing Technology Co., Ltd. provides comprehensive sealing solutions. We specialize in the research, manufacturing, and sale of various seals and sealing materials. Our products have received certifications from organizations like the CCS Classification Society and have been tested by the Chinese Academy of Coal Sciences, ensuring their high quality and reliability. We offer expert guidance to help you select the most suitable packing for your specific needs and ensure correct installation, guaranteeing the safe and reliable operation of your equipment.

Eng

Eng  русский

русский